Well-killing workover method used with water plugging

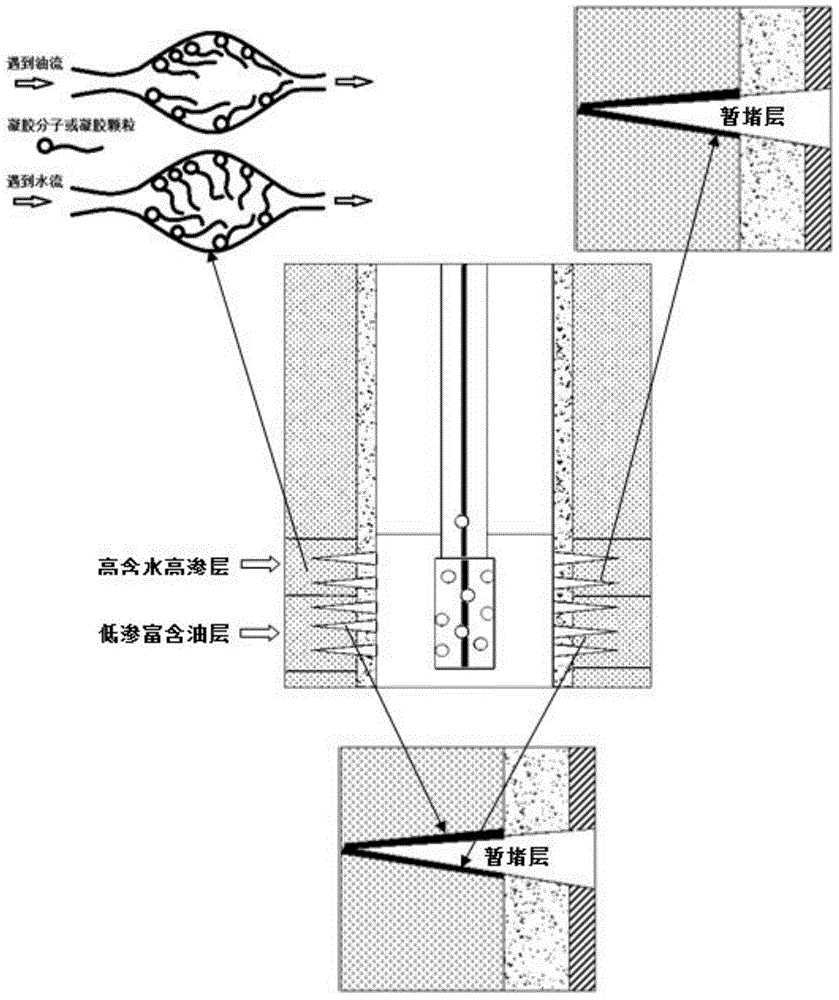

A joint operation and well killing technology, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problems of large filtration loss of clean brine, great influence of brine density, and reduction of water content in oil wells, etc. , to achieve the effects of improving gel performance, strong field operability, and convenient field configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

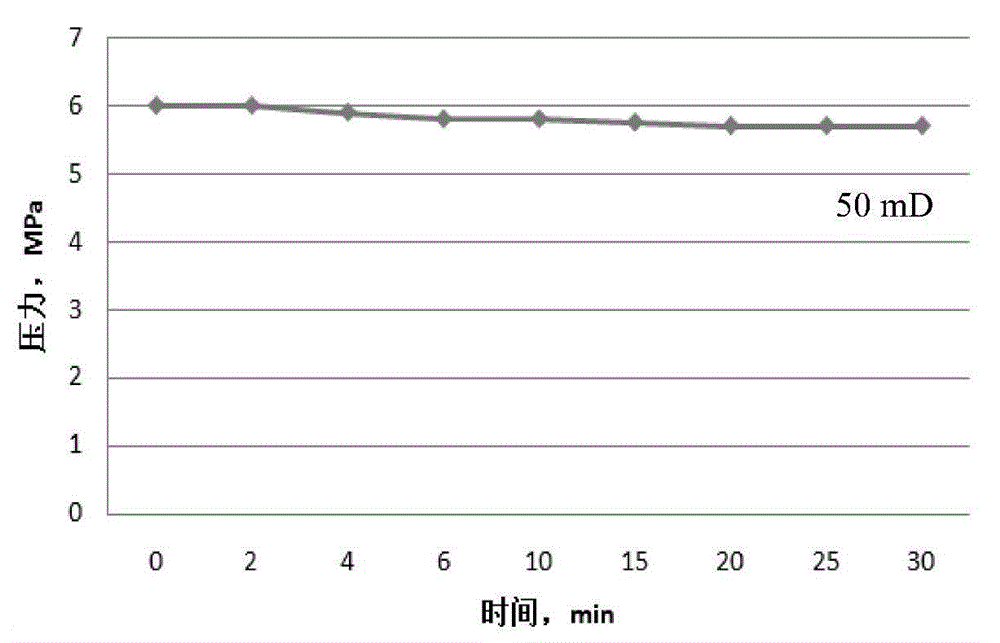

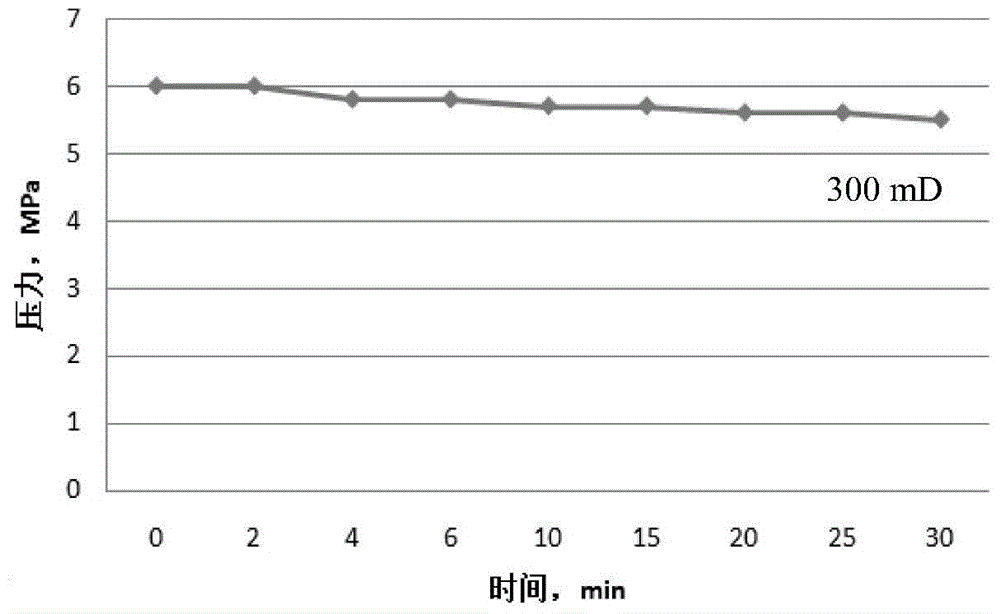

Embodiment 1

[0047] Reservoir X has a temperature of 25°C-35°C, a well depth of 500-700 meters, a permeability distribution of 0.054-1651.2mD, with an average of 582.3mD, and a porosity of 3.14%-32.45%, with an average of 20.1%. At present, the reservoir has entered the middle and late stages of development, and the formation heterogeneity is serious. The water content of oil wells is generally between 65% and 95%, and the formation pressure coefficient has dropped to 0.9-1.02. Oil wells in the middle and later stages of production are faced with frequent workover problems. At present, brine is commonly used as well killing fluid, and a large amount of leakage often occurs, which will seriously affect the water saturation around the wellbore, resulting in a significant decline in oil well production after workover. And the resumption cycle is longer, which affects the efficiency.

[0048] According to the current development situation of the work area, it is planned to adopt a well killing...

Embodiment 2

[0074] For low-pressure formations, use gel particle type low-density well killing fluid to kill the well, add gel particles with a mass concentration of 3.5% in clear water, let the gel particles fully expand at 50°C, and finally form a gel particle type low-density well. Density kill fluid, free water content 3 . The indoor simulation of well killing and workover is as described in Example 1. This method also achieves good leak prevention and water shutoff effects, and improves the productivity of oil wells after workover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com