Modified lithium ion battery high-nickel anode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsatisfactory battery discharge capacity, poor cycle stability, high residual lithium, etc., to improve cycle performance and safety performance, cost Low and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

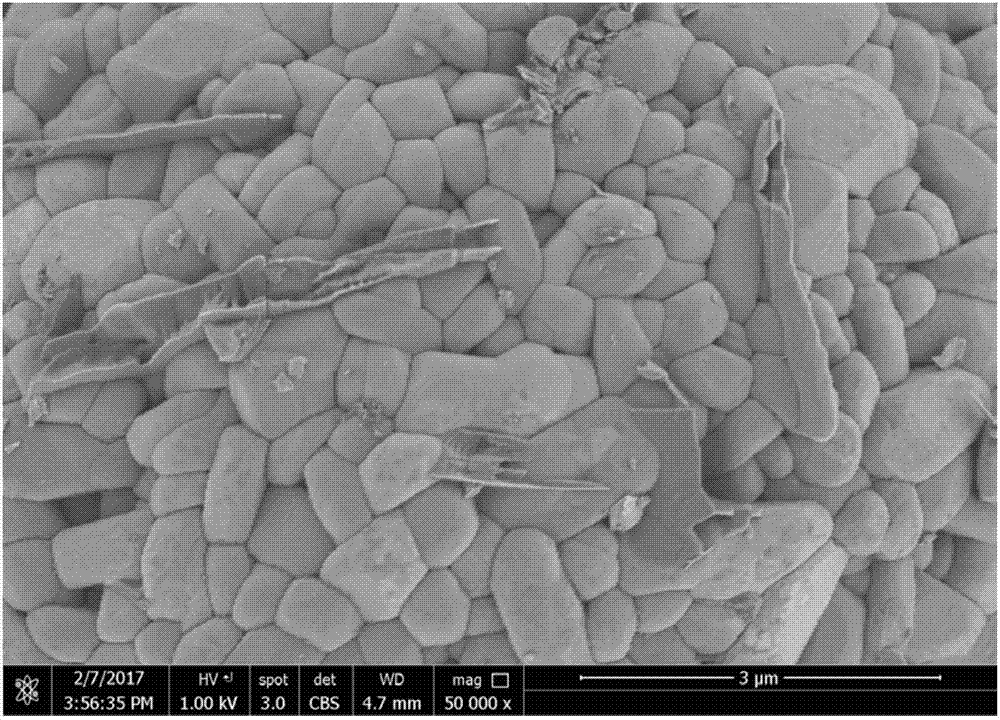

[0035] In terms of mass ratio, high nickel cathode material: deionized water is 1:2, tin source: high nickel cathode material is 1:1500. First weigh 100g LiNi 0.8 co 0.1 mn 0.1 o 2 The material was added to 200mL deionized water, stirred and washed at 1000r / min for 10min, filtered, dried in a vacuum oven at 120°C for 4h, and passed through a 400-mesh sieve to obtain a washed high-nickel cathode material. Grind the tin oxide again, pass through a 200-mesh sieve, weigh 0.067g of the sieved tin oxide powder and 100g of the washed positive electrode material into the ball mill jar at the same time, place on the ball mill and mix evenly, discharge, sieve, and Under 90% oxygen atmosphere, heat up to 500°C at a heating rate of 3°C / min, sinter at a constant temperature for 5 hours, cool, crush, and sieve to obtain a water-washed and tin-coated modified lithium-ion battery high-nickel cathode material. After testing, the mass of tin in the obtained high-nickel cathode material is L...

Embodiment 2

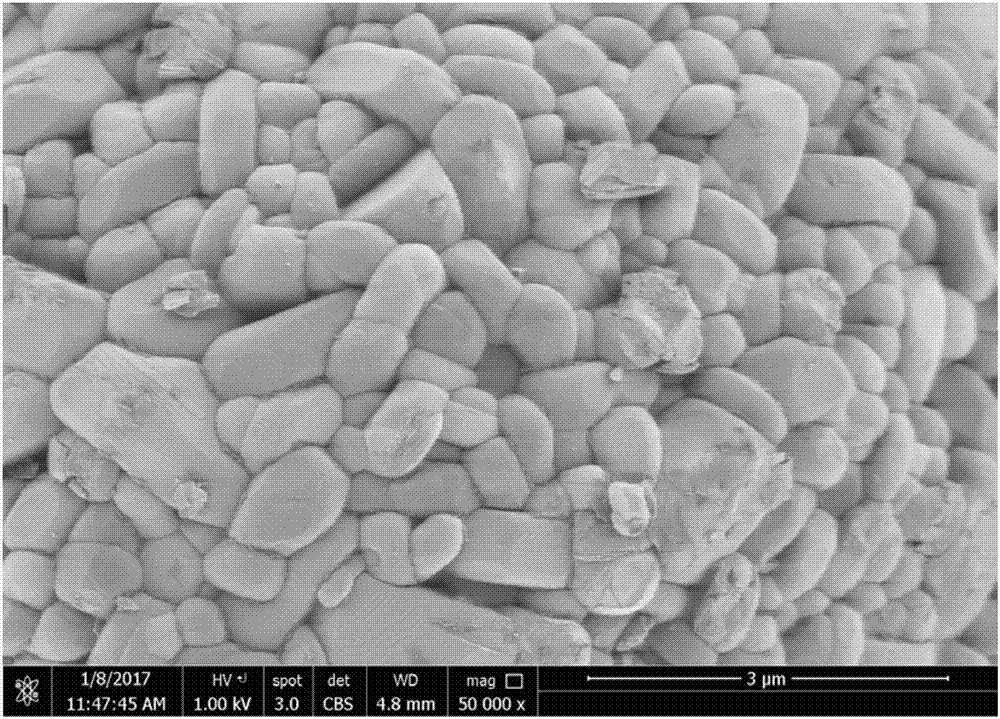

[0043] In terms of mass ratio, high nickel positive electrode material: deionized water is 1:2, tin source: high nickel positive electrode material is 1:750. First weigh 100g LiNi 0.8 co 0.1 mn 0.1 o 2 The material was added to 200mL deionized water, stirred and washed at 1000r / min for 10min, filtered, dried in a vacuum oven at 120°C for 4h, and passed through a 400-mesh sieve to obtain a washed high-nickel cathode material. Then grind the tin oxide, pass through a 200-mesh sieve, weigh 0.134g of the sieved tin oxide powder and 100g of the washed positive electrode material, and add them to the high-efficiency mixer to mix evenly, discharge, sieve, and mix in 80% oxygen Under the atmosphere, the temperature was raised to 500°C at a heating rate of 3°C / min, sintered at a constant temperature for 5 hours, cooled, crushed, and sieved to obtain a lithium-ion battery high-nickel positive electrode material with a uniform tin coating on the surface. After testing, the mass of ti...

Embodiment 3

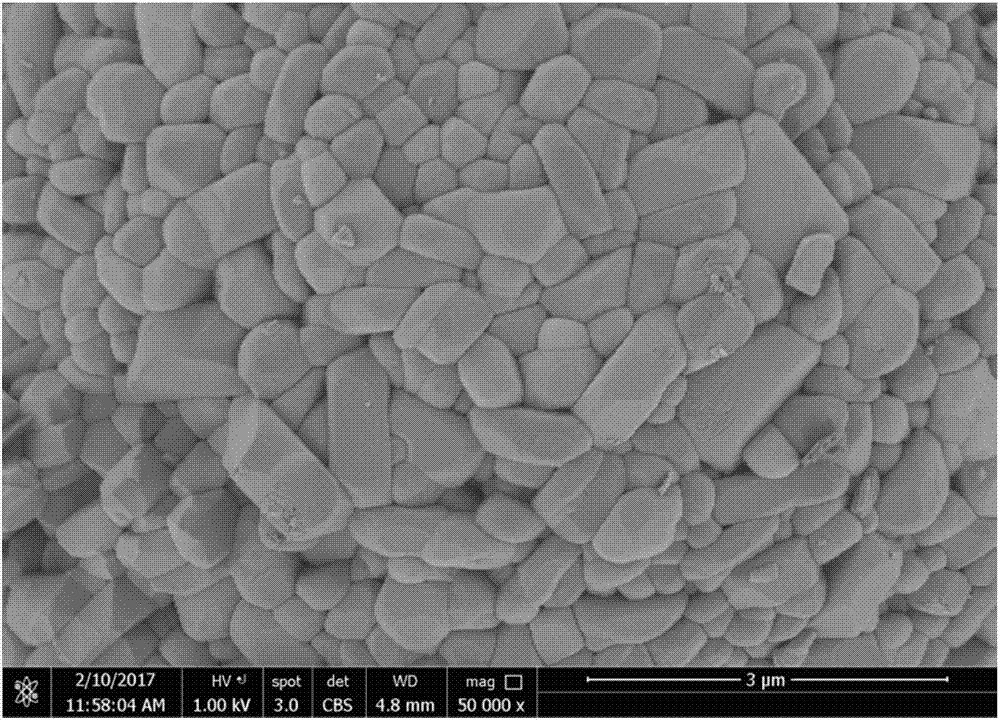

[0045] In terms of mass ratio, high nickel positive electrode material: deionized water is 1:4, tin source: high nickel positive electrode material is 1:750. First weigh 100g LiNi 0.8 co 0.1 mn 0.1 o 2 The material was added to 400mL deionized water, stirred and washed at 1000r / min for 5min, filtered, dried in a vacuum oven at 120°C for 4h, and passed through a 400-mesh sieve to obtain a washed high-nickel cathode material. Grind the tin oxide again, pass through a 300-mesh sieve, weigh 0.134g of the sieved tin oxide powder and 100g of the washed positive electrode material into the ball mill jar at the same time, place on the ball mill and mix evenly, discharge, sieve, and Under an 80% oxygen atmosphere, heat up to 550°C at a heating rate of 3°C / min, sinter at a constant temperature for 4 hours, cool, crush, and sieve to obtain a lithium-ion battery high-nickel cathode material with evenly coated tin on the surface. After testing, the mass of tin in the obtained high-nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com