Method of adopting gray scale mode in write-through photoetching system to improve exposure graph quality

A lithography system and a technology for exposing graphics, which are applied in microlithography exposure equipment, photolithography exposure devices, etc., can solve the problems of increasing hardware costs, affecting production capacity, and increasing the time consumption of the exposure system of lithography machines. Guarantee production capacity and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

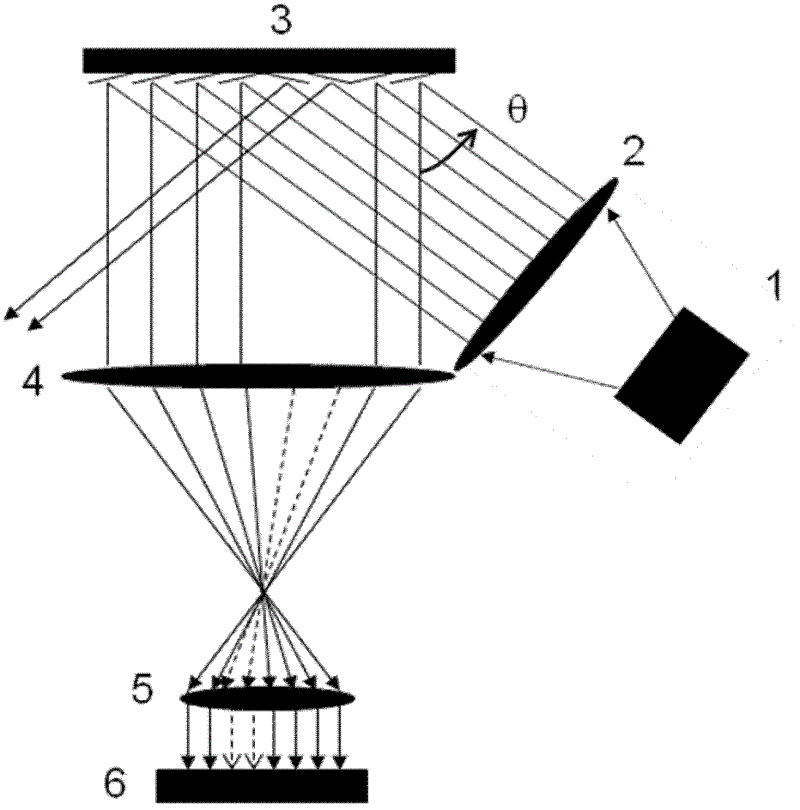

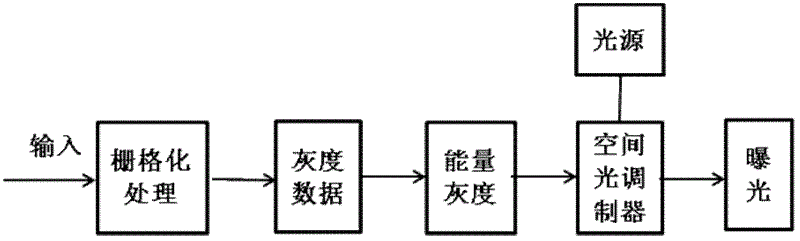

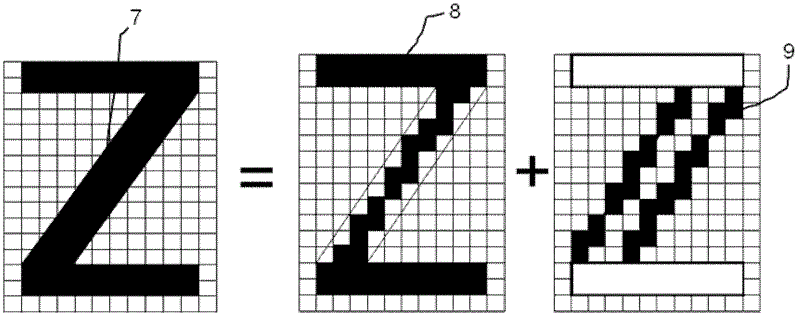

[0032] Such as figure 1 As shown, the method for improving the quality of exposure patterns in the direct-writing lithography system using gray scale includes a telecentric imaging system composed of an exposure light source 1, a condenser lens system 2, a spatial light modulator 3, an eyepiece 4 and an objective lens 5, and a substrate. 6. The light emitted by the exposure light source 1 is converged and homogenized by the condenser lens system 2 and then incident on the spatial light modulator 3 at a certain angle θ. After being modulated by the spatial light modulator 3, the incident light is imaged on the substrate 6 through the telecentric imaging system (mask plate or wafer), the characteristic pattern generated by the micromirror array of the spatial light modulator 3 must be processed before being transmitted to the spatial light modulator 3, and the exposure light source is turned on at the same time, and the characteristic pattern is transferred to the substrate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com