Automatic mud removing device of bucket wheel machine

A bucket wheel machine, automatic technology, applied in the direction of soil mover/shovel, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of small inner wall capacity of the bucket, affecting continuous work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

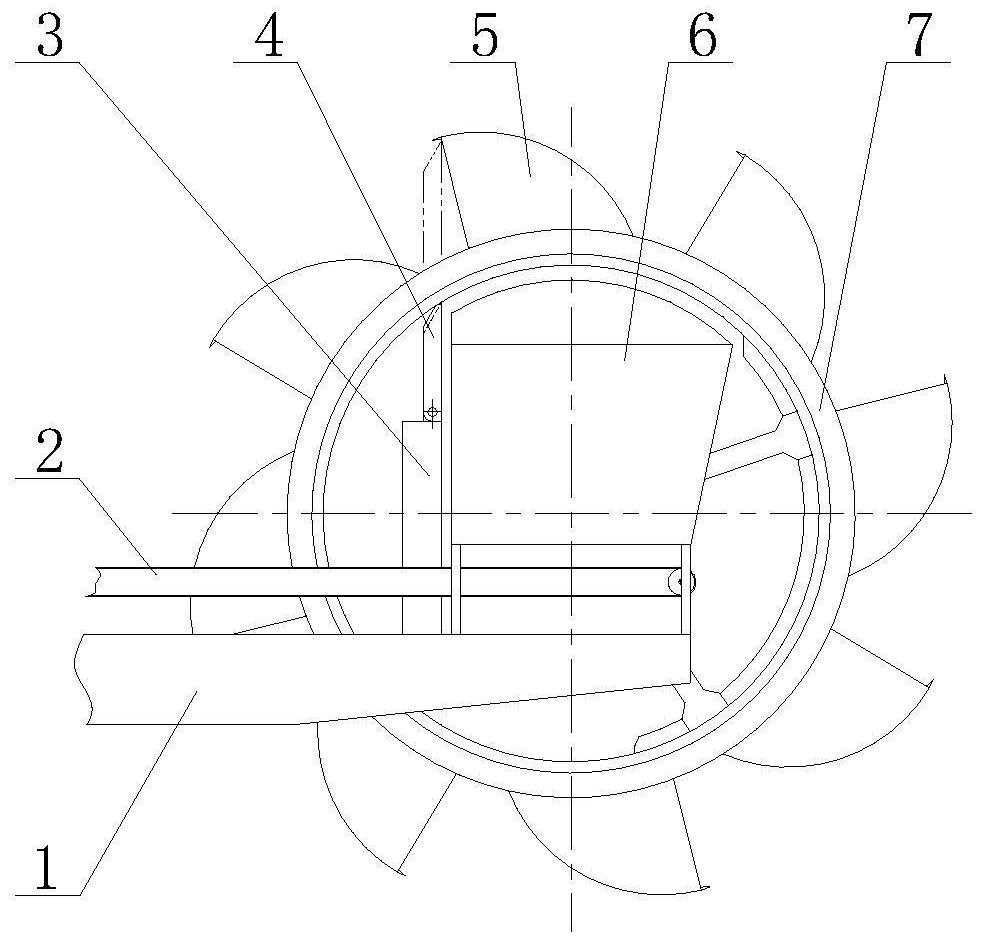

[0017] see figure 1 , the present invention provides a technical solution: bucket wheel machine automatic desilting device, including bucket wheel disk 7, the outer wall of the bucket wheel disk 7 is fixedly arranged with uniformly arranged buckets 5, the front side of the bucket wheel disk 7 The wall is fixed with a bucket wheel support truss 1, the upper side wall of the bucket wheel support truss 1 is fixed with a belt conveyor 2, and the right end of the upper side wall of the belt conveyor 2 is fixed with a receiving hopper 6. The hopper 6 extends above the rear wall of the belt conveyor 2 to the bottom of the bucket 5, the left end of the receiving hopper 6 below the bucket 5 is longitudinally fixed with a scraper mechanism 3, and the upper end of the scraper mechanism 3 is fixed with a A three-sided scraper 4, the upper end of the three-sided scraper 4 is in contact with the inner wall of the bucket 5 during relative movement.

[0018] The side wall of the bucket wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com