Battery plate for improving active material utilization

A battery plate and active material technology, applied to battery electrodes, lead-acid battery electrodes, electrode carriers/collectors, etc., to achieve the effects of reducing battery weight, improving adhesion, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

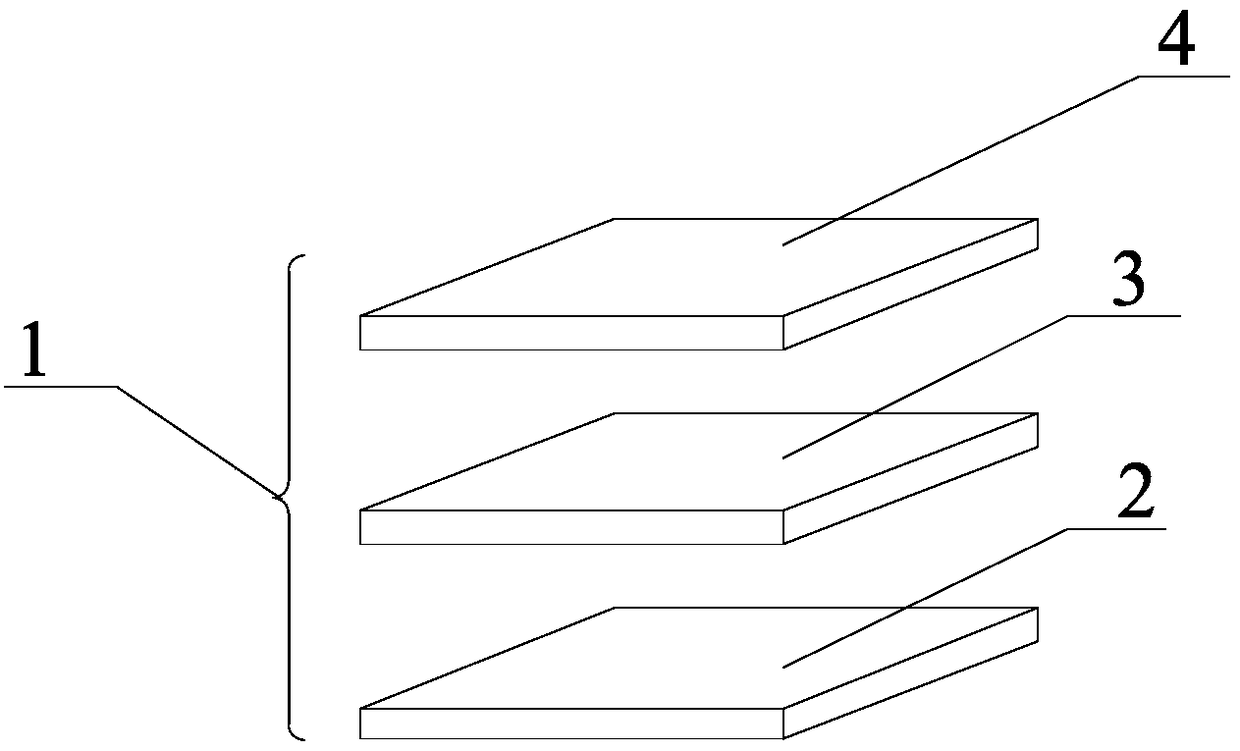

[0025] refer to figure 1 , the present embodiment provides a battery pole plate that improves the utilization rate of active materials, the battery pole plate 1 includes: a grid strip, a lead paste 4; the above-mentioned grid strip includes a metal strip layer 2 and a metal strip layer The lead alloy plating layer 3 on the surface of the layer 2; the above-mentioned lead paste 4 is coated on the outer surface of the lead alloy plating layer 3.

[0026] Wherein, the thickness of the lead alloy coating 3 coated on the surface of the metal strip layer is 0.05 mm, and is coated by electroplating.

[0027] The preparation process of the above-mentioned metal strips is as follows: heating the copper-aluminum alloy to a molten state, casting the molten copper-aluminum alloy continuously to form a metal strip, rapidly cooling it and pressing it into a metal strip through a pressure roller, and at the same time, the above-mentioned The continuous punching of the metal strips is carrie...

Embodiment 2

[0031] refer to figure 1 , the present embodiment provides a battery pole plate that improves the utilization rate of active materials, the battery pole plate 1 includes: a grid strip, a lead paste; the above-mentioned grid strip includes a metal strip layer 2 and a metal strip layer coated 2 the lead alloy coating 3 on the surface; the above-mentioned lead paste 4 is coated on the outer surface of the lead alloy coating.

[0032] Wherein, the lead alloy plating layer 3 coated on the surface of the metal strip layer 2 has a thickness of 0.40 mm, and is coated by electroplating.

[0033] The preparation process of the above-mentioned metal strips is as follows: heating the copper-aluminum alloy to a molten state, casting the molten copper-aluminum alloy continuously to form a metal strip, rapidly cooling it and pressing it into a metal strip through a pressure roller, and at the same time, the above-mentioned The continuous punching of the metal strips is carried out to make t...

Embodiment 3

[0037] refer to figure 1 , the present embodiment provides a battery pole plate that improves the utilization rate of active materials, the battery pole plate 1 includes: a grid strip, a lead paste; the above-mentioned grid strip includes a metal strip layer 2 and a metal strip layer coated 2 the lead alloy coating 3 on the surface; the above-mentioned lead paste 4 is coated on the outer surface of the lead alloy coating 3 .

[0038] Wherein, the thickness of the lead coating or the lead alloy coating coated on the surface of the metal strip layer is 0.80mm, and the coating is carried out by spraying.

[0039] The preparation process of the above-mentioned metal strips is as follows: heating the copper-aluminum alloy to a molten state, casting the molten copper-aluminum alloy continuously to form a metal strip, rapidly cooling it and pressing it into a metal strip through a pressure roller, and at the same time, the above-mentioned The continuous punching of the metal strips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com