Double-electrolyte secondary battery

A secondary battery and dual electrolyte technology, applied in secondary batteries, secondary battery repair/maintenance, organic electrolytes, etc., can solve the problems of many failure mechanisms, short cycle life of lead-acid batteries, shortage of resources, etc., and achieve utilization rate boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

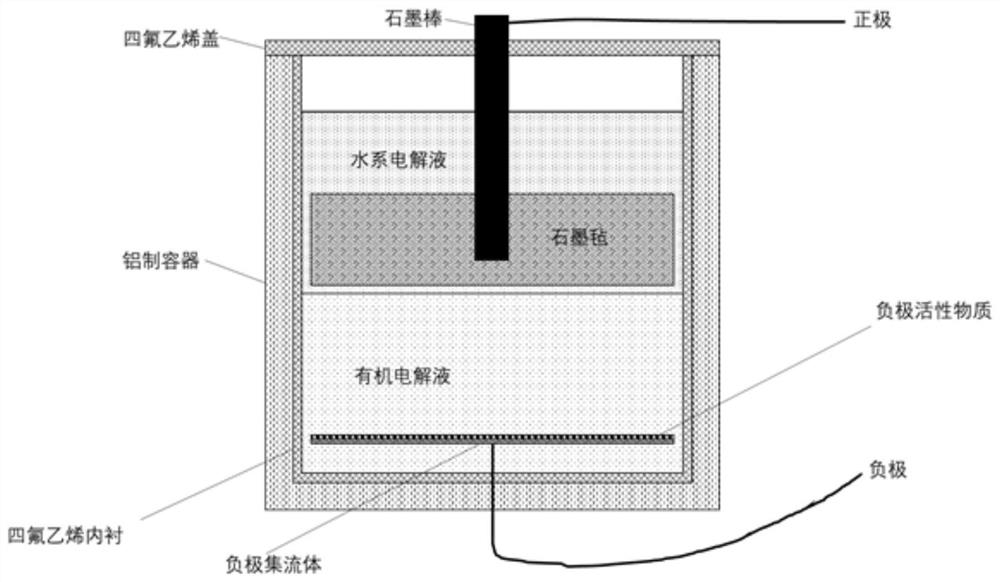

Embodiment 1

[0072] As attached to the manual figure 1 As shown, an aluminum shell with an inner diameter of 50mm, a wall thickness of 3mm, and a height of 50mm is open at the top; A wire and seal it, and the wire is connected to a circular titanium mesh with an inner diameter of 40mm and a thickness of 0.5mm in the shell, which is used as the negative electrode collector of the battery. Deploy the electrode slurry of sodium titanium phosphate, conductive carbon black, polyvinylidene fluoride binder and N-methylpyrrolidone with a mass ratio of 8:1:1, and coat the negative electrode collector with 0.5mm thick electrode slurry and then drying to obtain a battery negative electrode in which the negative electrode active material and the current collector are closely bonded. Then add 100ml of propylene carbonate solution of 1mol / L sodium trifluoromethanesulfonimide sodium in the container as an organic electrolyte, then configure 1mol / L sodium sulfate aqueous solution as an aqueous electrolyt...

Embodiment 2

[0074] Using the same battery structure as in Example 1, prepare an electrode slurry of lithium titanium phosphate, conductive carbon black, and polyvinylidene fluoride binder with a mass ratio of 8:1:1, and coat the aluminum foil with The electrode slurry with a thickness of 0.5 mm is then dried to obtain a battery negative electrode in which the negative electrode active material and the current collector are closely bonded. Then add 100ml of propylene carbonate solution of 1mol / L lithium bistrifluoromethanesulfonimide lithium in the container as an organic electrolyte, then configure a 1mol / L lithium sulfate aqueous solution as an aqueous electrolyte, and take 100ml of Add a certain amount of sodium ferrocyanide and ammonium ferrocyanide to the water-based electrolyte to form an electrolyte solution containing ferrocyanide ions with a concentration of 0.05mol / L, and add it to the container. It can be seen that the two electrolytes in the container are immiscible, and most o...

Embodiment 3

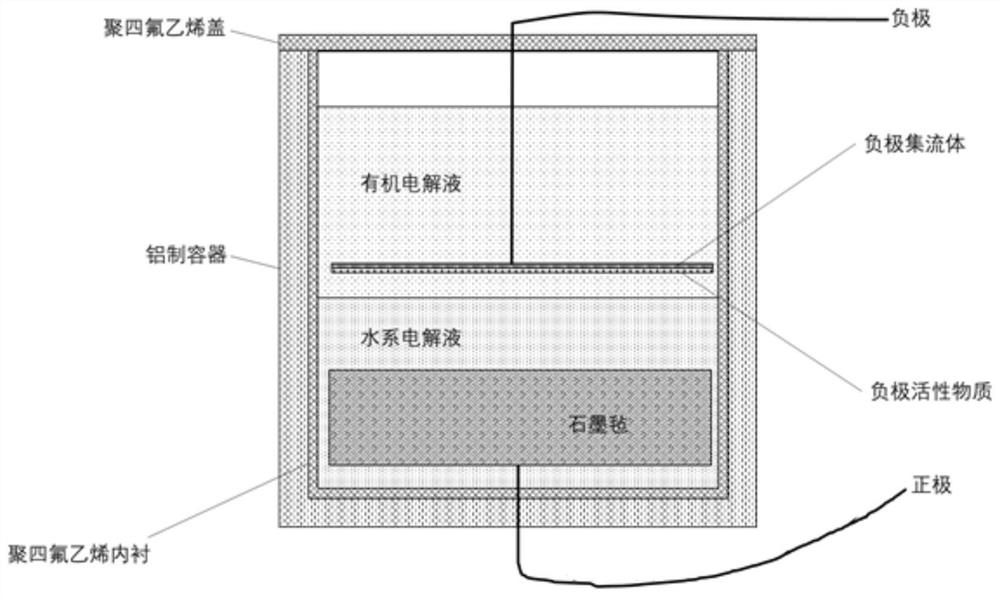

[0076] As attached to the manual figure 2 As shown, an aluminum shell with an inner diameter of 50mm, a wall thickness of 3mm, and a height of 50mm is open at the top; A 0.5mm conductive carbon fiber is directly connected to the external circuit through and sealed in the middle. The carbon fiber is connected to a 10mm thick hydrophilic graphite felt with a diameter of 40mm in the shell to keep the two conductive. The shell is made of polytetrafluoroethylene. The completed lid has a hole in the center of the lid, and the negative current collector is a circular graphite sheet with an inner diameter of 40mm and a thickness of 0.5mm. The conductive carbon fiber is used to connect the graphite sheet to pass through the hole in the center of the lid to connect to the external circuit. Deploy the electrode slurry of poly(2-vinylanthraquinone), conductive carbon black, and polyvinylidene fluoride binder with a mass ratio of 8:1:1, and coat the graphite sheet with a thickness of 0.5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com