Slurry coating device for lithium ion battery

A lithium-ion battery and coating device technology, which is applied to the device for coating liquid on the surface, battery electrodes, electrode collector coatings, etc. Fluid and other problems to achieve the effect of solving the wrinkles or damage of the collector, eliminating potholes, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

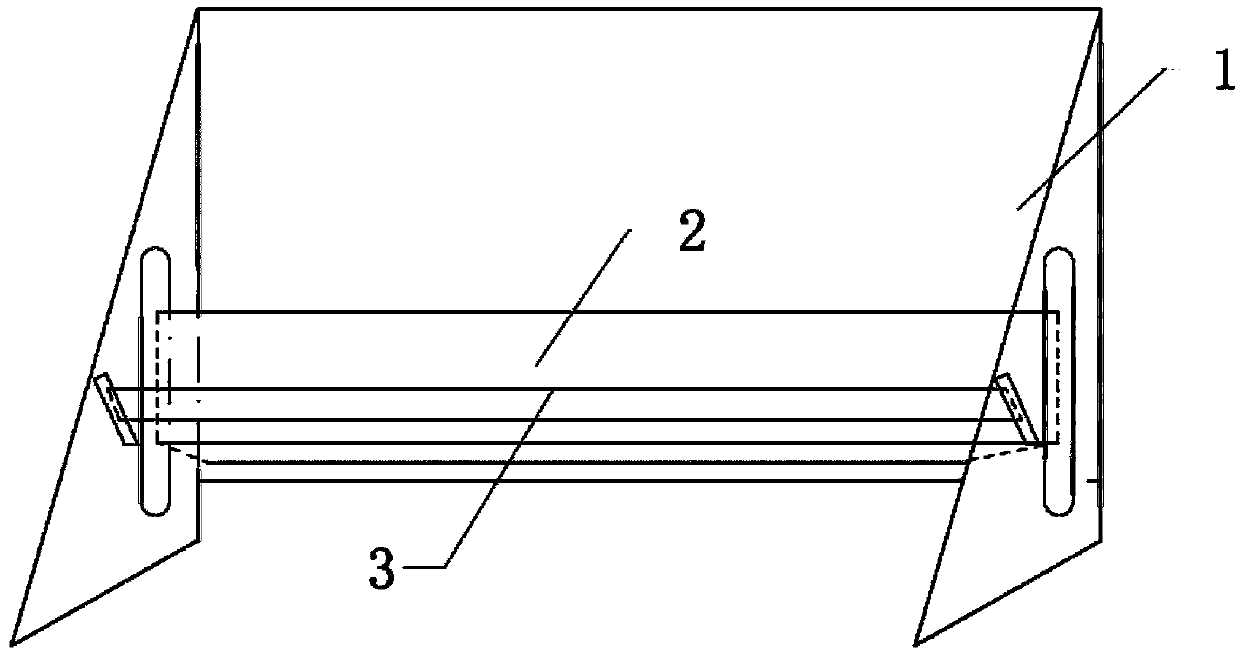

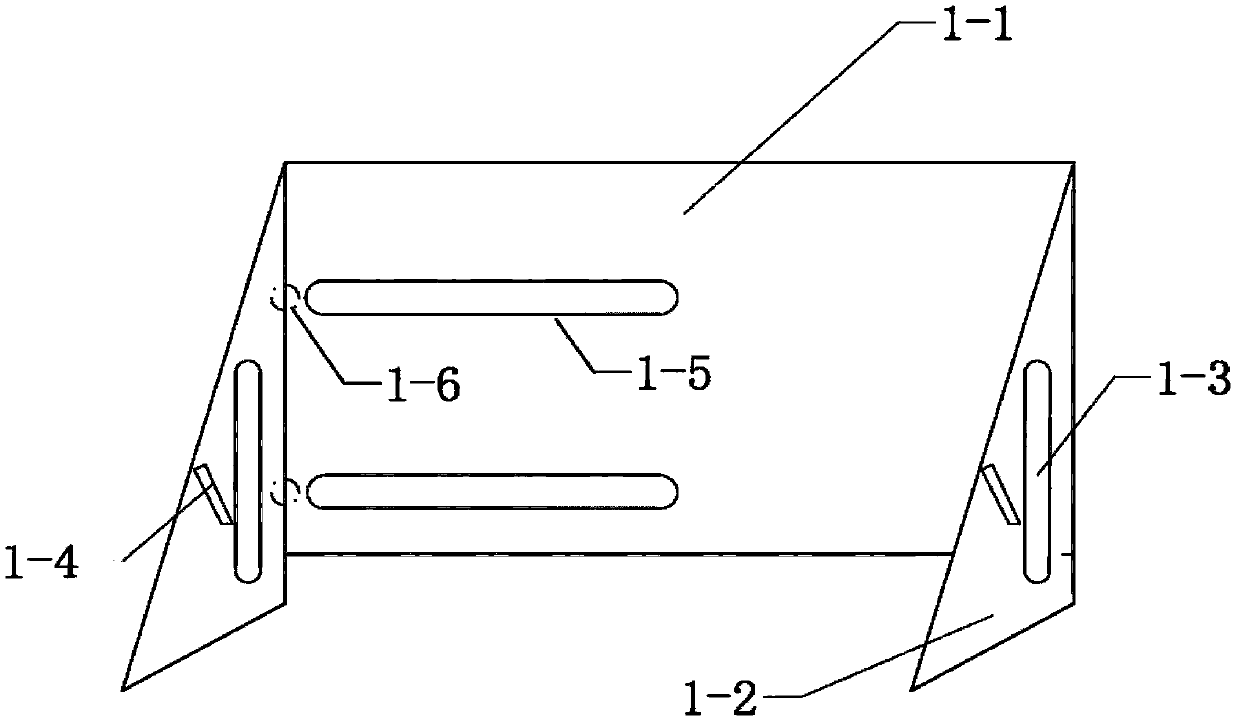

[0045] A lithium ion battery slurry coating device. Including: a fixed frame (1), a scraper (2) set on the fixed frame (1), a feeding baffle (3) set on one side of the scraper (2), the fixed frame consists of a rectangular fixed frame (1-1) and Composed of triangular support plates (1-2) on both sides, a scraper height adjustment groove (1-3) for adjusting the height of the scraper is set on the triangular support plate, and a scraper height adjustment groove (1-3) on the triangular support plate One side is provided with a feeding baffle height adjustment groove (1-4) for adjusting the height of the feeding baffle, the feeding baffle is set at an angle of 45-60 degrees with the scraper, the fixed frame (1), the scraper (2) and the feeding The baffle (3) forms the feeding chamber.

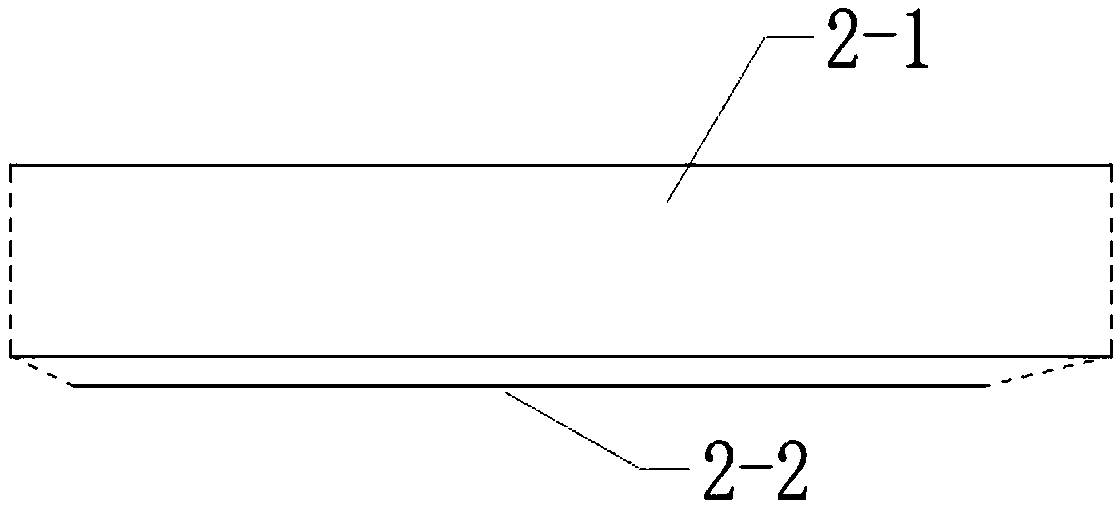

[0046] The scraper (2) is made up of a stainless steel plate (2-1) and a round bar (2-2) of pure titanium material welded to the bottom of the stainless steel plate (2-1).

[0047] The scraper he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com