High-speed feeding machine for punching machine

A feeder, punching technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of slow manual feeding, low stamping efficiency, hand injuries, etc., to ensure personal safety and improve stamping. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

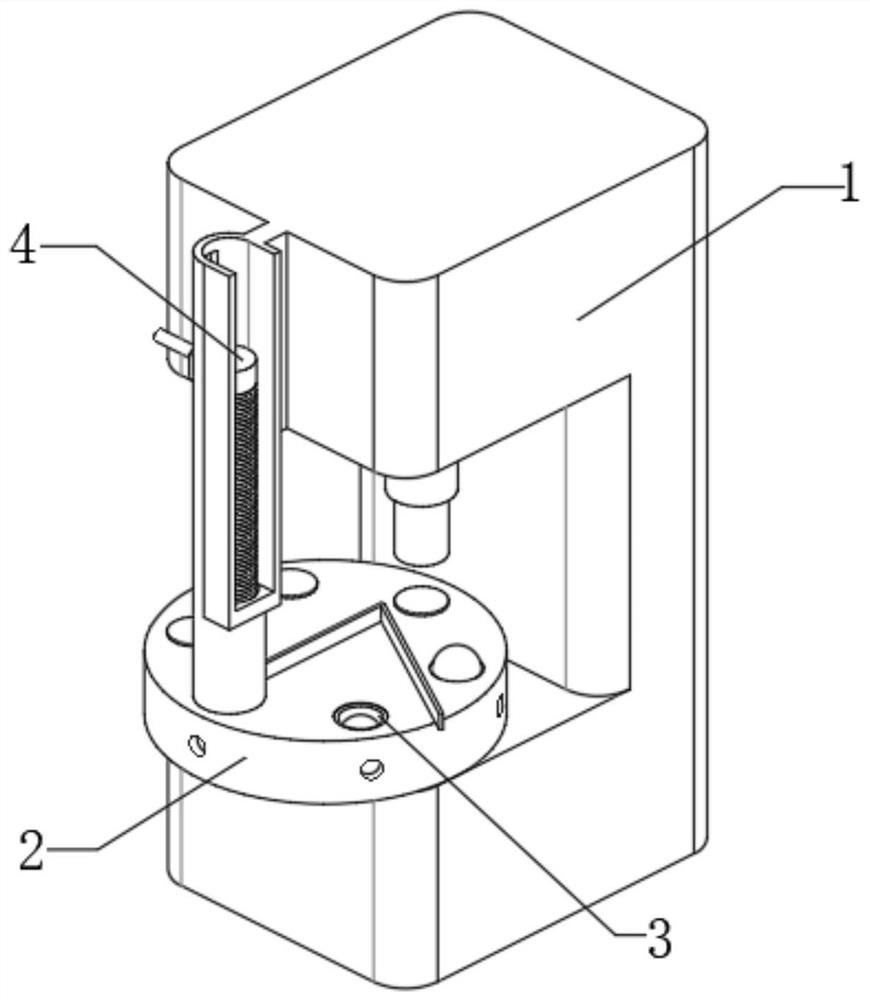

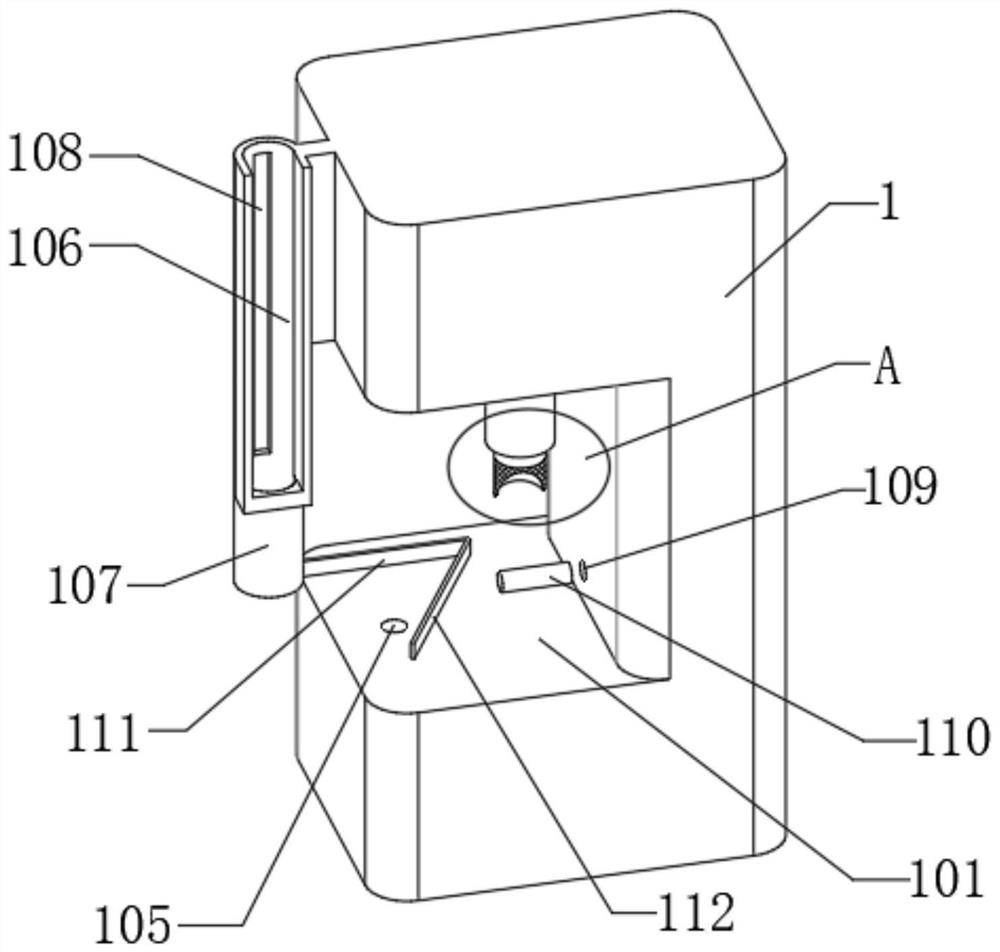

[0034] The embodiment of the present invention discloses a high-speed feeder for a punching machine, which includes a punching machine body 1, a turntable 2, a support ring 3, a pressing block 4 and a spring 5:

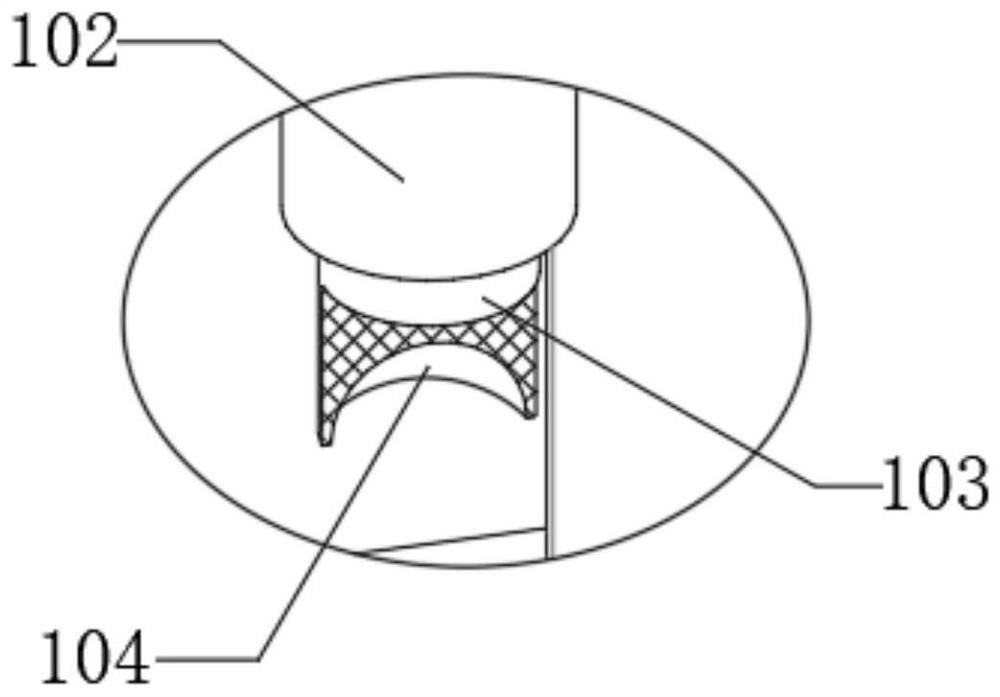

[0035] According to attached figure 1 , 2 As shown in and 3, a stamping chamber 101 is provided on the front of the punch body 1, and both sides of the stamping chamber 101 are connected to the punch body 1. A hydraulic cylinder 102 is installed on the upper surface of the stamping chamber 101, and the hydraulic cylinder 102 is arranged near the punching chamber. The position on the back of the chamber 101, the hydraulic cylinder 102 is slidably connected with the piston stamping rod 103, and the lower surface of the piston stamping rod 103 is provided with a hemispherical groove 104, starting the stamping chamber 101 can drive the hydraulic cylinder 102 to move up and down, and the stamping chamber 101 is controlled Under the command of the device, it reciprocates u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com