Bottle tube seal detection device

A sealing detection, bottle tube technology, applied in the direction of measuring device, fluid tightness test, liquid tightness measurement using liquid/vacuum degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

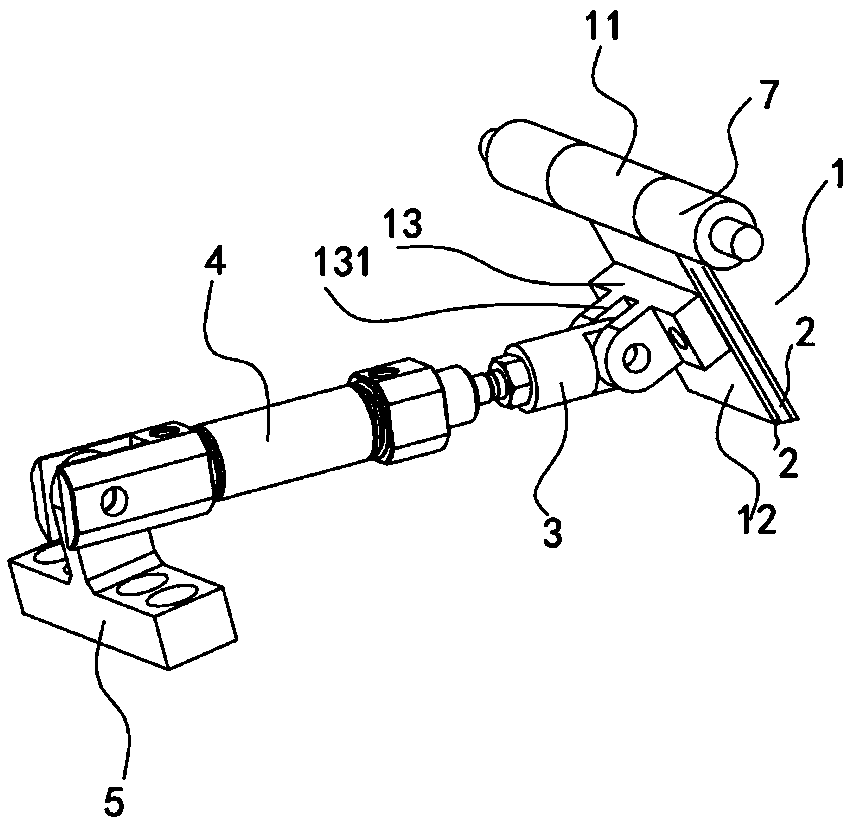

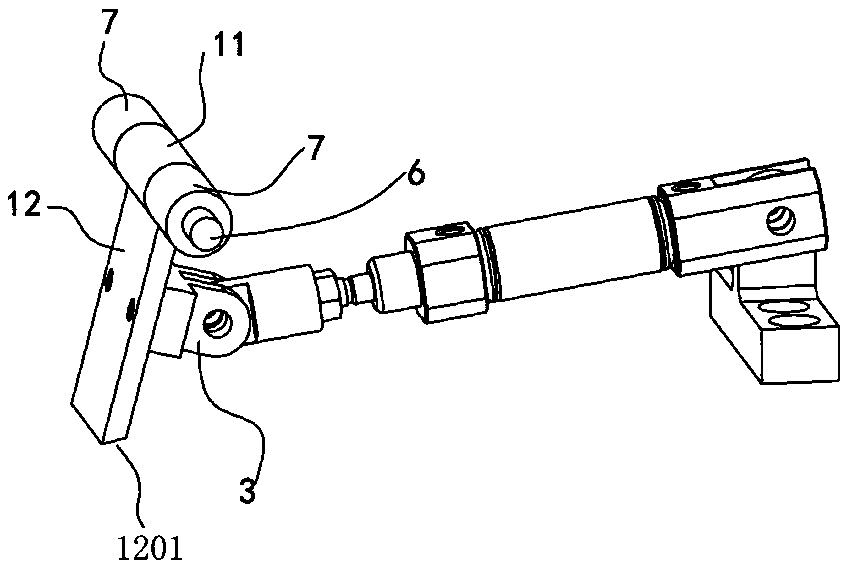

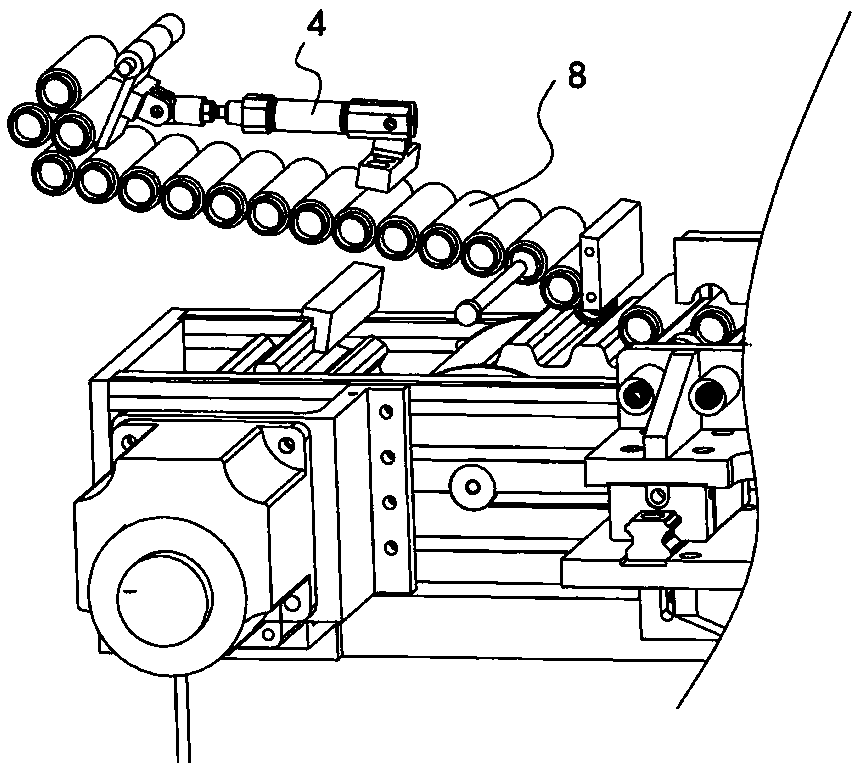

[0019] Please refer to Figure 1 to Figure 3 , the pipe body guide mechanism in the figure includes a rotating baffle 1, a connecting piece 3, a baffle cylinder 4, and a cylinder fixing seat 5.

[0020] The rotating baffle 1 includes a fixed end 11, a pusher end 12, and a connecting end 13; the fixed end 11 is a cylinder with a through-hole inside, and a rotating shaft 6 is installed in the through-hole, and the rotating shaft 6 is fixed on the guide for rotation. On the hopper, the function of the fixed end 11 is to fix the pusher end 12, and the pusher end 12 rotates around its center under the push of the baffle cylinder 4. In order to limit the position of the fixed end 11, the two sides of the fixed end 11 A limit post 7 is arranged at each end. The pushing end 12 is connected with the fixed end 11 and is located below the fixed end 11. Under the action of the pushing end 12, the pipe body 8 is pushed to move to change its position. The connecting end 13 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com