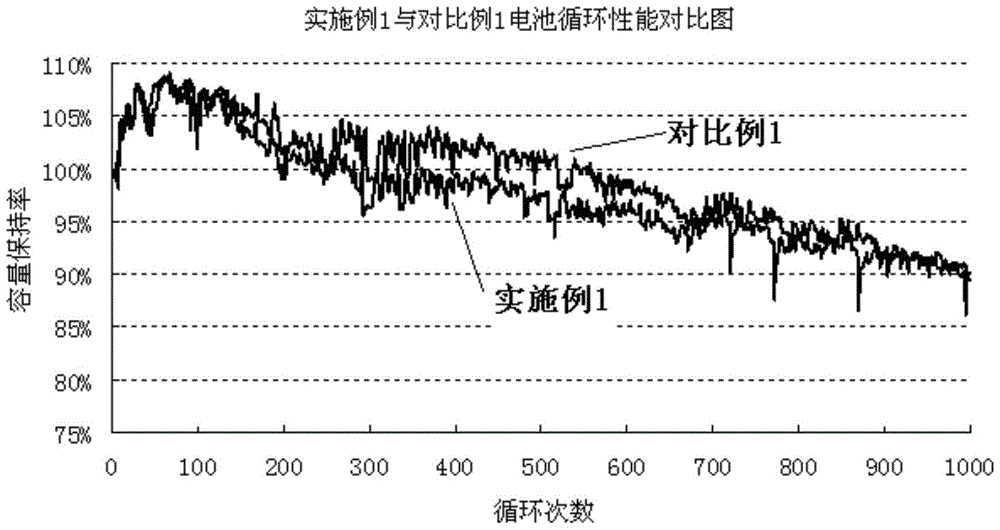

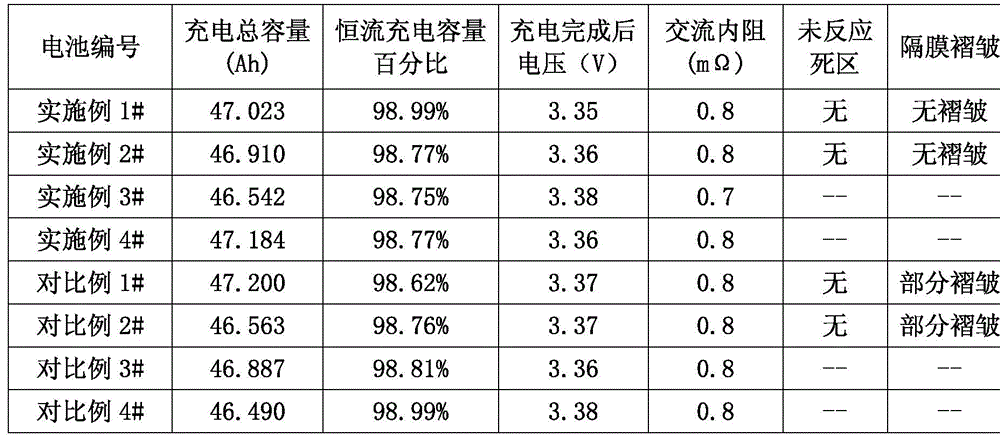

Rapid formation process of lithium iron phosphate battery

A lithium iron phosphate battery, fast technology, applied in the field of lithium-ion batteries, can solve the problems of low efficiency and long time consumption, achieve high efficiency, low energy consumption, and ensure battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, a square steel shell 40Ah lithium iron phosphate power battery is taken as an example, and the specific formation steps are as follows:

[0034] (1) After the battery assembly is completed, vacuumize and inject liquid three times, each injection volume is 110g, and seal;

[0035] (2) Put the battery in an incubator at 45°C for 12 hours, turn the battery over every 2 hours, and place the battery with all 6 sides facing down for 2 hours;

[0036] (3) After shelving is completed, the battery is ultrasonically treated for 15 minutes, the power of the ultrasonic treatment equipment is 100W, and the frequency of the ultrasonic wave is 15KHz;

[0037] (4) Measure the voltage and internal resistance of the battery, and record it, and the battery that does not meet the requirements will not be formed in the cabinet;

[0038] (5) Put the battery on the cabinet and charge it according to the following charging methods:

[0039] ①The battery is charged to 3.2V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com