Device and method for recovering residual powder on SLM molding substrates

A recovery method and powder technology, which is applied in the field of equipment for recovering residual powder on SLM molding substrates, can solve problems such as loss of inert gas, increase in production costs, and cleaning of difficult residual powder, so as to prevent flying around, save production costs, and avoid a large number of churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

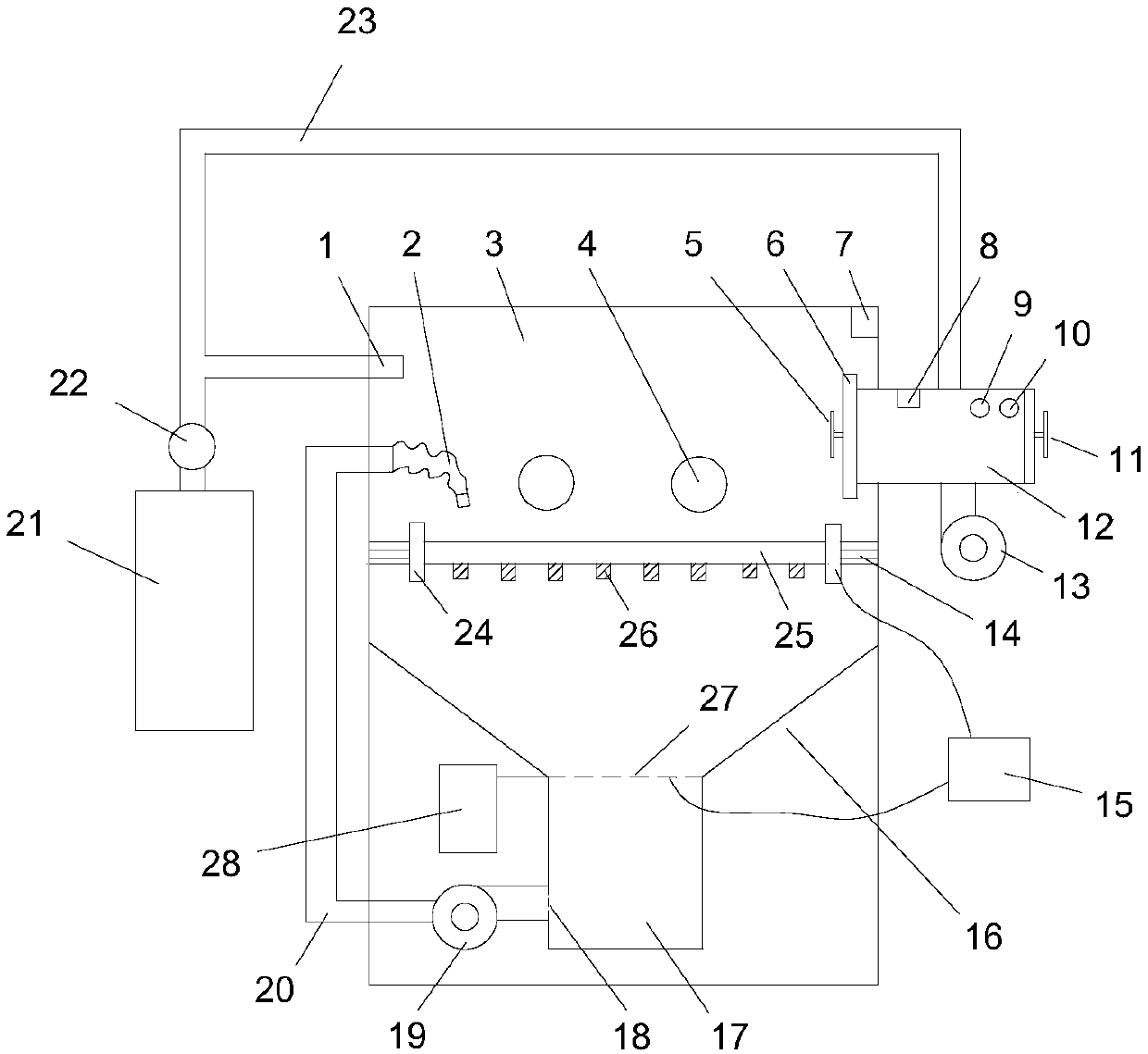

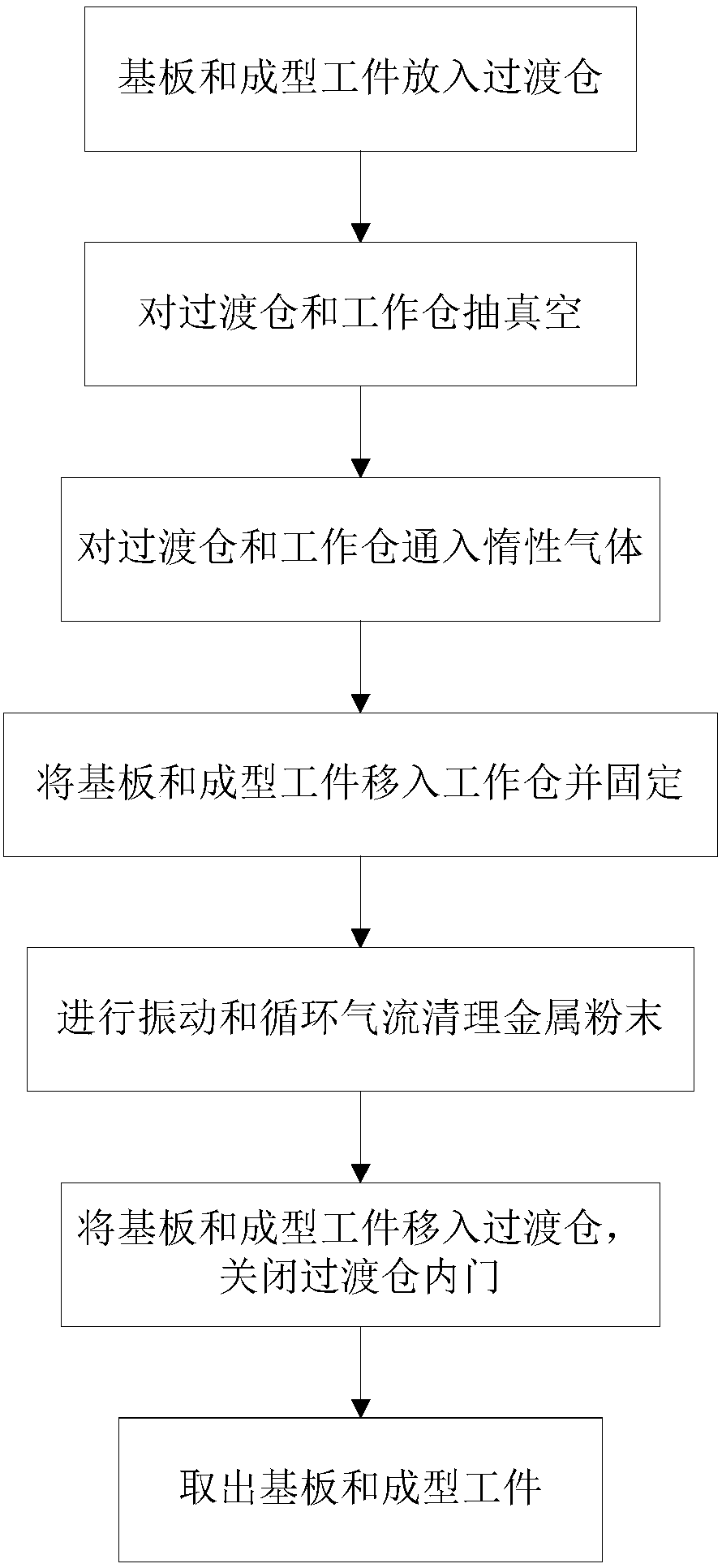

[0041] Such as figure 1 and figure 2 As shown, the device and method for recovering the residual powder on the SLM molding substrate of the present invention, when recycling the metal powder on the substrate 25 and the molding part 26, first open the inner door 6 through the inner door locking device 5, and then open the inner door 6 through the outer door locking device. 11 Open the outer door, put the substrate 25 and the molding parts 26 into the transition chamber 12, close and seal the outer door, vacuum the transition chamber 12 and the working chamber 3 through the vacuum pump 13 for 3 minutes, pass the time indicating device 9 and the pressure gauge 10 Observe separately. Open the gas storage tank 21 storing the inert gas after the vacuuming is completed, and pass Ar or N with a purity higher than 99.99% into the transition chamber 12 and the working chamber 3 through the inert gas pipe 23. 2 inert gas. The inflation time of the inert gas is 2 minutes, the inflatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com