New energy vehicle water-cooling motor shell manufacturing process and its structure

A technology for new energy vehicles and water-cooled motors, which is used in the manufacture of motor generators, casings/covers/supports, electrical components, etc. It can solve the problems of unstable production structure of motor casings and easy blockage of water channels, and achieve structural stability. Reliable, improved performance parameters, reasonable effect of manufacturing process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

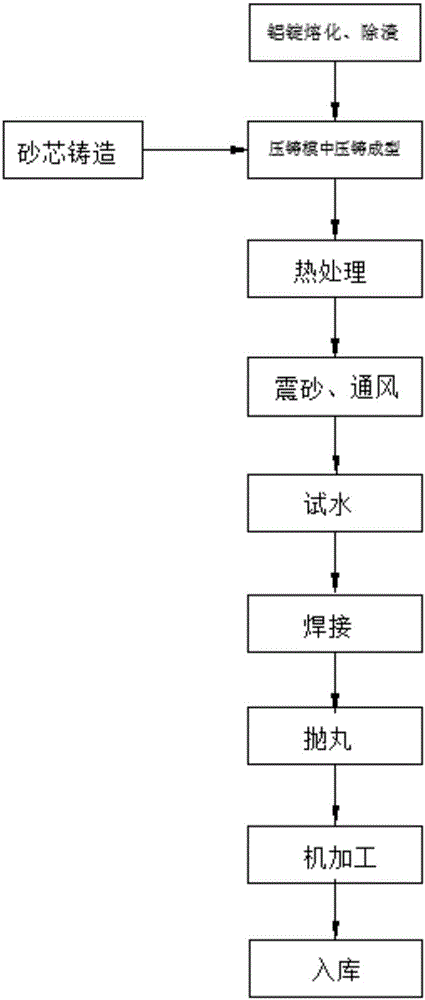

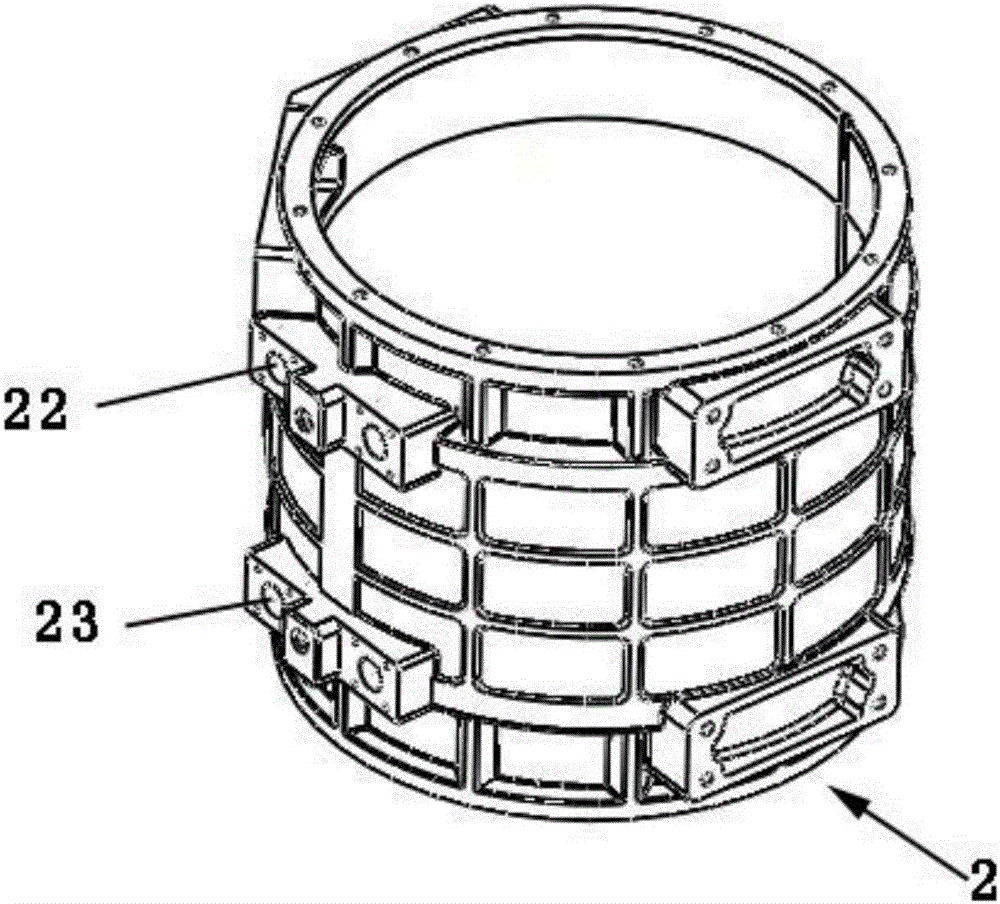

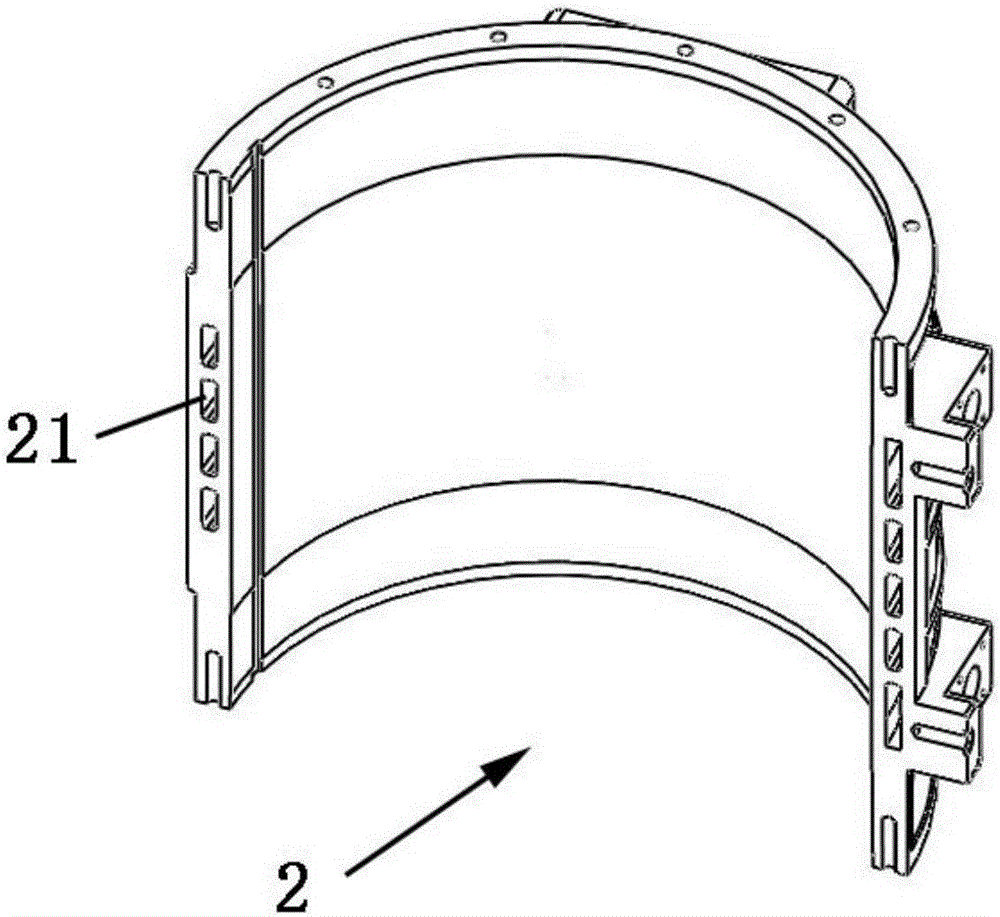

[0031] Such as Figure 1~3 As shown, a new energy vehicle water-cooled motor casing manufacturing process is manufactured in the following steps,

[0032] (a) Install the cast sand core piece 1 into the die-casting mold, the sand core piece 1 is divided into an installation part 11 and a spiral part 12, and the installation part 11 is clamped and positioned in the groove of the die-casting mold;

[0033] (b) Put the aluminum ingot into the melting furnace, the aluminum ingot is AC4B or AC2B or AC3AM or AC4C or A357, the melting furnace is heated to 700 ~ 720 ℃ to melt the aluminum ingot into molten aluminum, and the air pump drives the aluminum liquid to flow from the pipe In the die-casting mold, the spiral part 12 of the sand core piece 1 is completely immersed in the molten aluminum, and the mounting part 11 is exposed from the molten aluminum, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com