Organic metal iridium complex and organic light-emitting device application thereof

An organic light-emitting device, organometallic technology, applied in the direction of indium organic compounds, platinum group organic compounds, electric solid devices, etc., can solve the problems of lowering the sublimation temperature and failing to meet the requirements of OLED preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

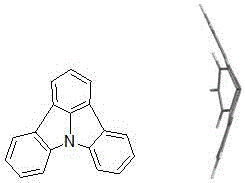

Image

Examples

Embodiment 1

[0093] Example 1: Synthesis of G-2 and G-3 luminescent organometallic iridium complexes

[0094]

[0095] According to the principle shown in the chemical reaction formula I-III, and the above synthetic chemical steps, without departing from the scope of the present invention, the following organometallic iridium compounds were synthesized, and the specific listed complexes were verified by mass spectrometry. For details, see Table 4 below:

[0096] Table 4 Example organometallic iridium complex luminescent material chemical structure and characterization

[0097]

[0098]

[0099]

[0100]

[0101]

[0102]

[0103]

[0104]

Embodiment 2

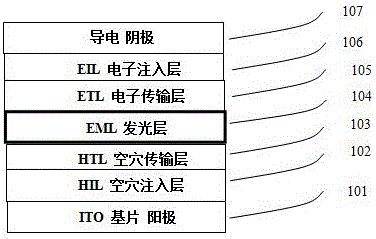

[0105] Example 2 Application example of evaporated OLED device:

[0106] Evaporated OLED devices made: in a background vacuum up to 10 -5 Pa's multi-source evaporation OLED preparation equipment adopts the following device mechanism: Luminescent dopant

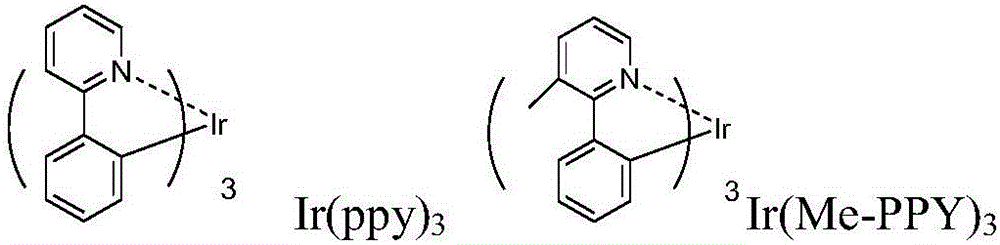

[0107] Using different organometallic iridium light-emitting complexes and host materials, OLED light-emitting devices were fabricated and examined for comparison. Comparative known organometallic iridium complex materials used:

[0108]

[0109] Compare with known host materials:

[0110]

[0111] Table 5: Performance of vacuum-evaporated OLED devices (room temperature@1000nits)

[0112]

[0113] Compared with comparative devices A and B, Table 5 illustrates that the organometallic iridium complex light-emitting dopant material of the present invention is applied to OLED light-emitting devices relative to the contrasting green light doping material Ir(pCz)3 and the contrasting red light doping The material ...

Embodiment 3

[0114] Embodiment 3 solution is made OLED device:

[0115] On the surface of a conductive glass ITO, after solvent and plasma cleaning, the solution is spin-coated with PEDOT conductive polymer as the hole injection layer, and the poly(triphenylamine-9.9-diheptane fluorene) PTW solution spin-coated film is used as the hole transport layer. , then use 2% host material DBTT / luminescent dopant green light or red light (doping concentration 8% by weight) mixed solution to spin-coat, and then heat to 160 ° C for 30 minutes under nitrogen to make the film become infusible Insoluble; second spin coat with solution Finally in a background vacuum up to 10 -5 In Pa's multi-source evaporation OLED preparation equipment, the electron injection layer is evaporated Preparation of OLED devices ITO / PEDOT / PTW / DBTT: 5% light-emitting dopant / TPBi / LiF / Al.

[0116] Table 6: Performance of solution spin-coated OLED devices (room temperature@1000nits)

[0117]

[0118] Comparing Devices C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com