Silicon solar cell and manufacturing method thereof

A silicon solar cell and silicon-based technology, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency of solar cells, reduce the short-circuit current of solar cells, and reduce the efficiency of cells, etc., so as to enhance charge transport capacity, improve charge separation and transmission, etc. Performance, the effect of reducing the density of defect states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

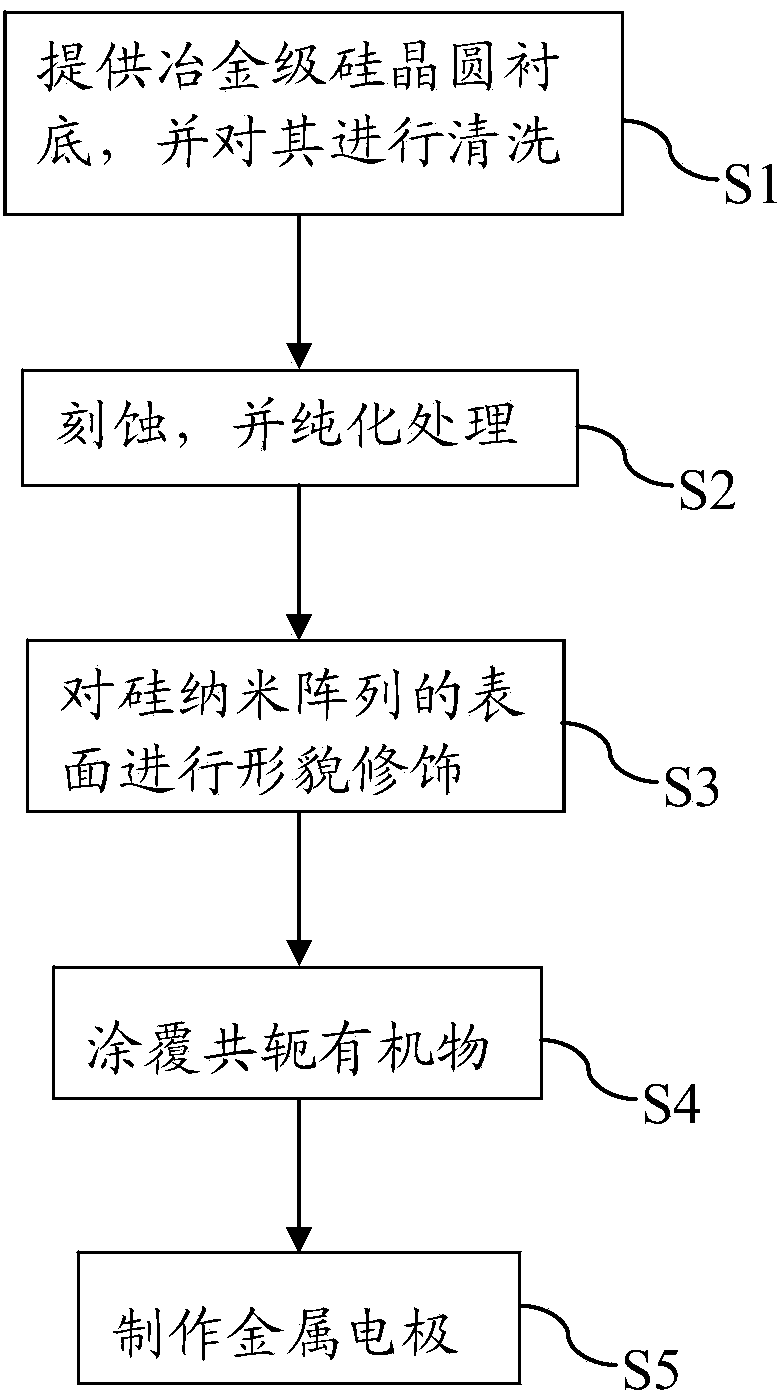

[0039] Such as figure 1 Shown, the present invention provides a kind of preparation method of silicon solar cell, it comprises the steps:

[0040] S1. Provide metallurgical grade silicon wafer substrates and clean the silicon wafer substrates;

[0041] S2. Etching the cleaned metallurgical-grade silicon wafer substrate in an etching solution, and obtaining a regularly arranged silicon nano-array after purification;

[0042] S3. modifying the surface of the silicon nano-array to obtain a metallurgical-grade silicon nano-structure whose surface has been modified;

[0043]S4. Uniformly coat the conjugated organic matter on the surface of the obtained metallurgical grade silicon nanostructure, and perform annealing treatment after coating;

[0044] S5. Fabricate metal electrodes on the surface coated with the conjugated organic matter and the metallurgical grade silicon wafer substrate.

[0045] Wherein, the above step S2 specifically includes: putting the cleaned metallurgical...

Embodiment 1

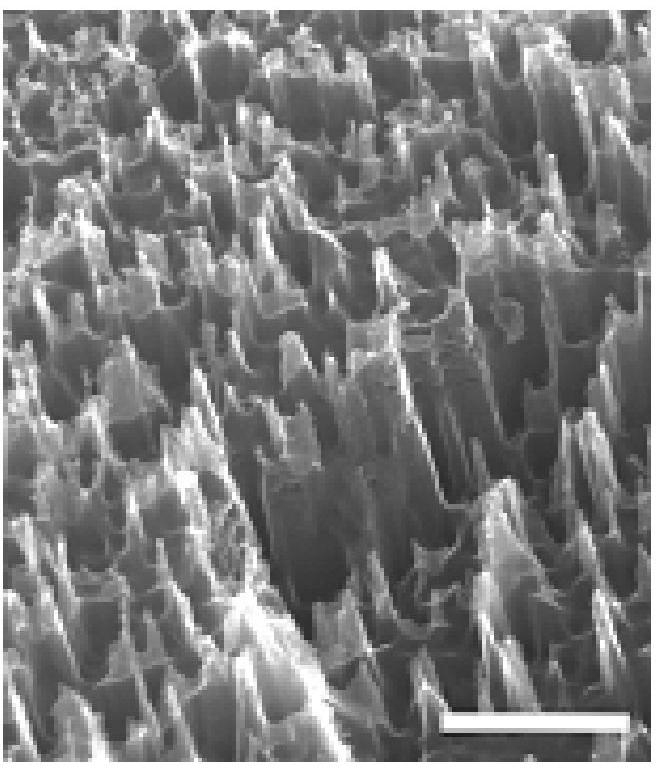

[0058] Such as image 3 , 4 As shown, provide a metallurgical grade silicon wafer, clean it, soak it in a diluted HF solution for at least 15 minutes, rinse it with deionized water and dry it with nitrogen, and put it in a glove box for use. Modification of metallurgical-grade silicon wafers with tetramethylammonium hydroxide. Then use PEDOT:PSS solution to spin-coat a layer of PEDOT:PSS film on the metallurgical grade silicon wafer at a speed of 9000 rpm, and then perform annealing treatment at 125°C. Then, under high vacuum conditions, an Ag electrode with a thickness of 200 nm is thermally evaporated on the PEDOT:PSS film, and an Al electrode is thermally evaporated on the back of the metallurgical grade silicon wafer to obtain the silicon solar cell of the present invention.

[0059] For the silicon solar cell prepared in this example, at room temperature, use a xenon lamp to simulate sunlight AM1.5, with a light intensity of 100mWcm -2 Under the conditions, the measure...

Embodiment 2

[0064] Such as Figure 7 Shown is the transmittance curves of metallurgical-grade silicon wafers with different thicknesses provided in this embodiment.

[0065] Provide metallurgical-grade silicon wafers of different thicknesses, soak metallurgical-grade silicon wafers of different thicknesses in diluted HF solution for at least 15 minutes, then rinse with deionized water and dry with nitrogen, and put them in the glove box for use. Modification of metallurgical-grade silicon wafers with tetramethylammonium hydroxide. Using the PEDOT:PSS solution, spin-coat a layer of PEDOT:PSS film on the silicon wafer at a speed of 9000 rpm, and then perform annealing treatment at 125°C. Then, an Ag electrode with a thickness of 200 nm is thermally evaporated on the PEDOT:PSS film under high vacuum conditions, and an Al electrode is thermally evaporated on the back of the silicon wafer to obtain the silicon solar cell of the present invention.

[0066] For the silicon solar cell prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com