Turbocharger with double vane nozzle system

A turbocharger and double-blade technology, which is applied to gas turbine devices, machines/engines, non-displacement pumps, etc., can solve the problems of reducing the thermal efficiency of the turbine, turbulent air flow, etc., to reduce the cross-sectional area of the channel, reduce the loss of flow resistance, Avoid the effect of air turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the number of fixed blades 8 as 8, the number of moving blades 7 as 8, and the blade inlet angle, that is, the installation angle, is 21°.

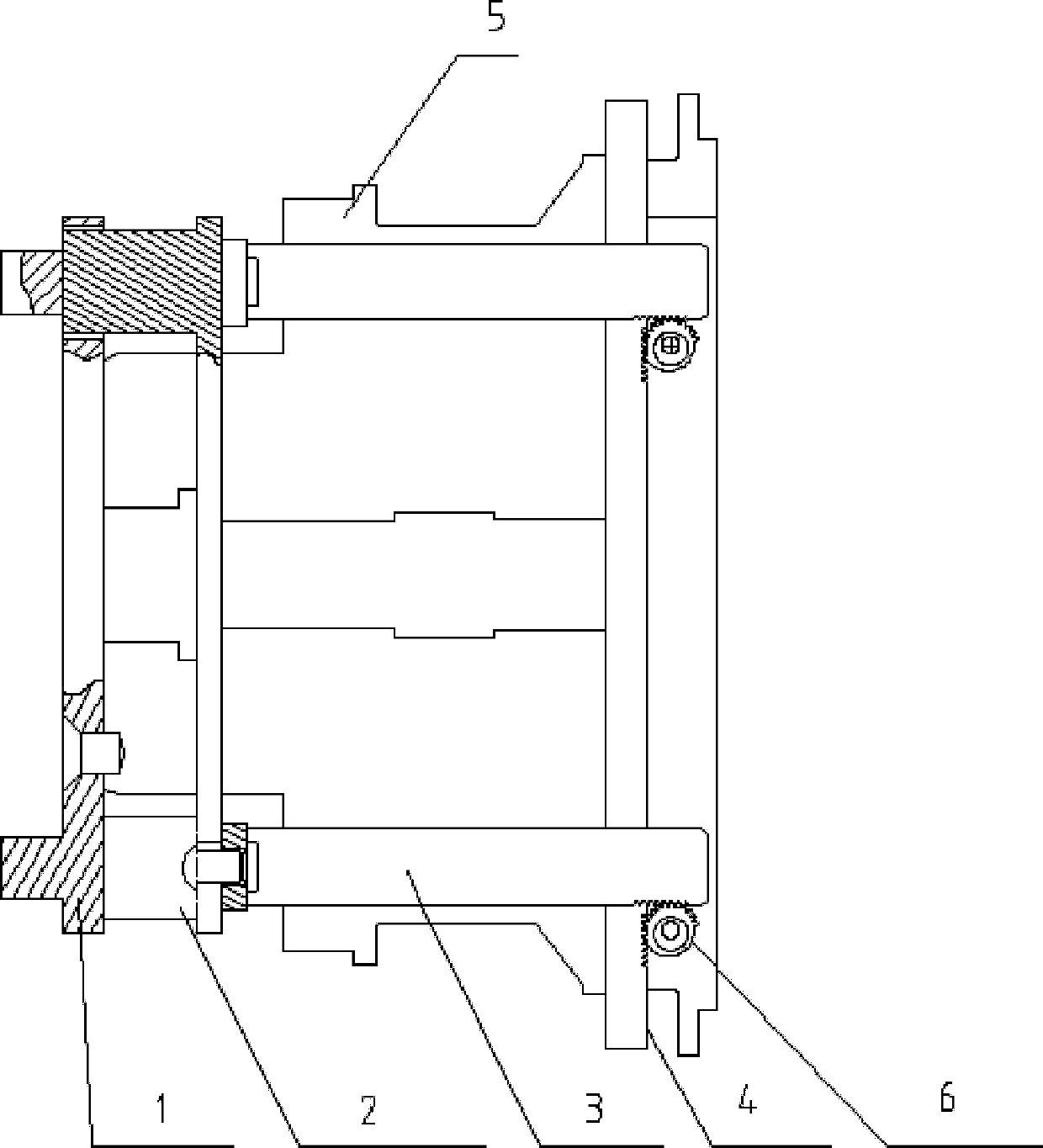

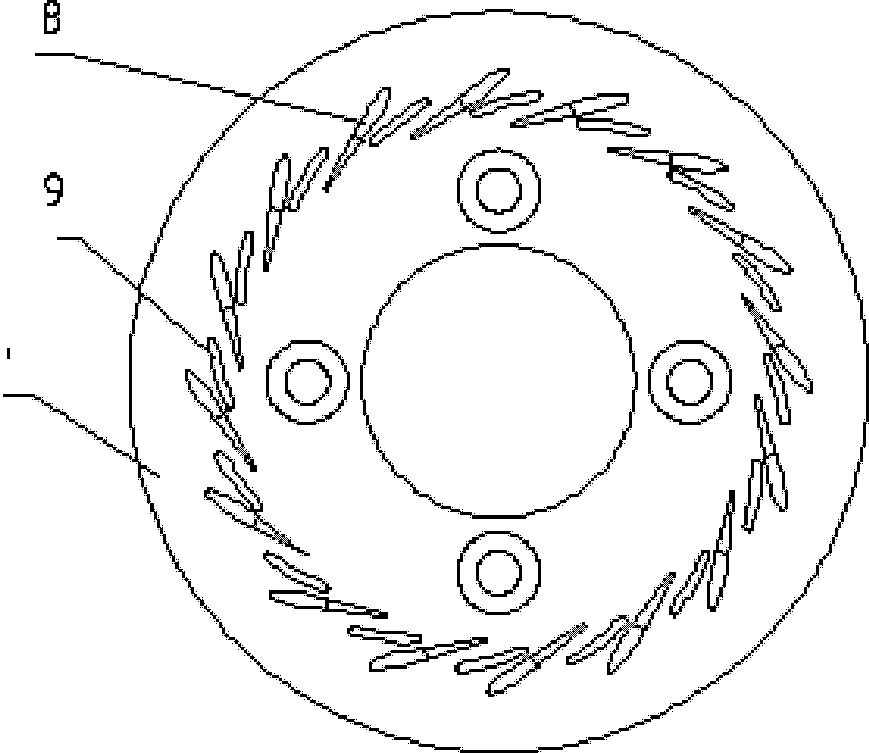

[0029] Such as figure 1 , 4 , 10, there is a set of fixed blades 8 on the front end of the fixed nozzle ring 1, which is shaped like an airfoil, and there are blade-shaped holes 9 between the fixed blades 8, and there is a central hole in the middle of the fixed nozzle ring 1, which is set in the middle shell 5 The outer ring is fixed on the middle shell 5 by screws, and the rear end of the fixed nozzle ring 1 is equipped with a linear movable nozzle plate 2 .

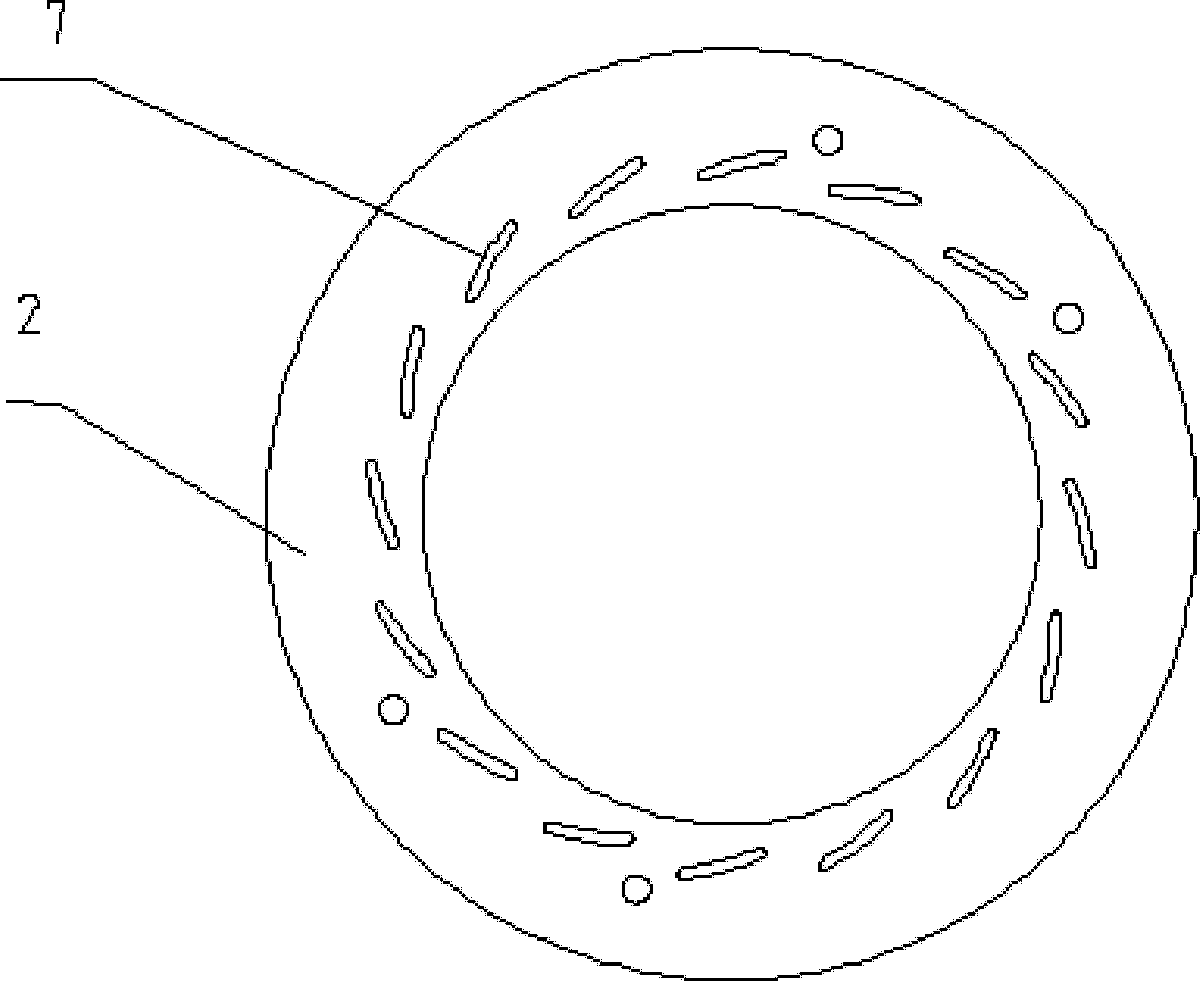

[0030] Such as figure 2 , 10 As shown, there is a group of moving blades 7 on the front end of the linearly moving nozzle plate 2 , the shape of the moving blades 7 is consistent with the shape of the blade hole 9 , and the moving blades 7 are movably inserted in the blade hole 9 .

[0031] Such as figure 1 , 5 , 6, and 10, fix the two rocker levers 3 on the r...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment is that the driving device for pushing the rack to move up and down is a solenoid valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com