Axial-flow type check valve capable of replacing internal part on line

A technology of axial flow and check valves, which is applied in the direction of lifting valves, valve details, control valves, etc., can solve the problems of long time-consuming disassembly and complex structures, and achieve the reduction of online maintenance time, simplification of top-loading structures, and reduction of production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

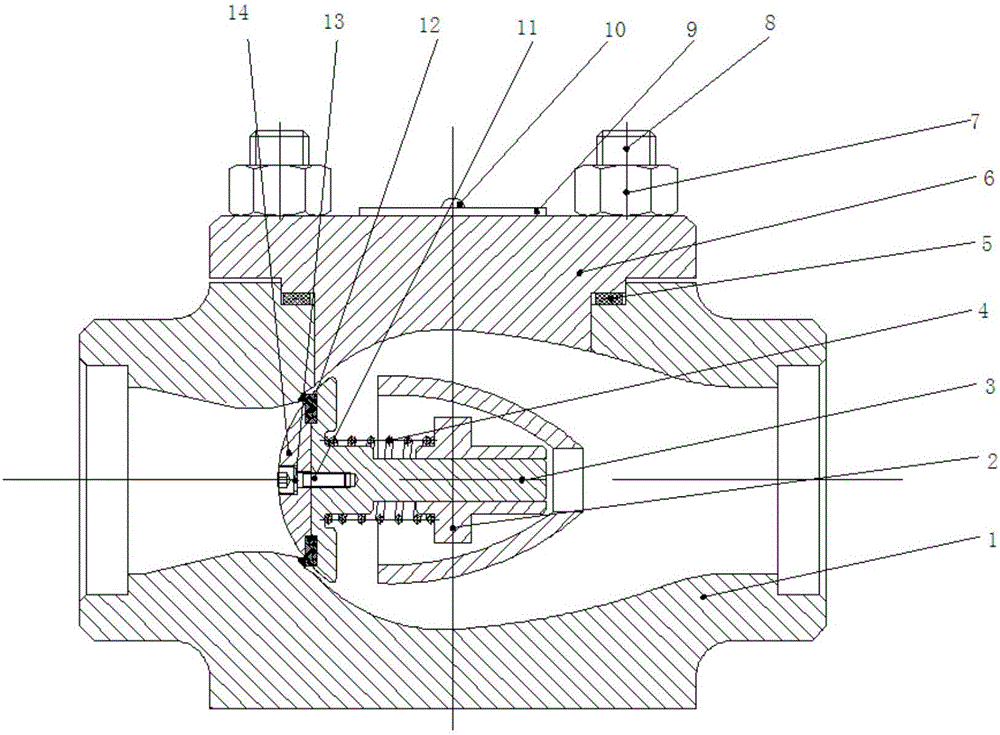

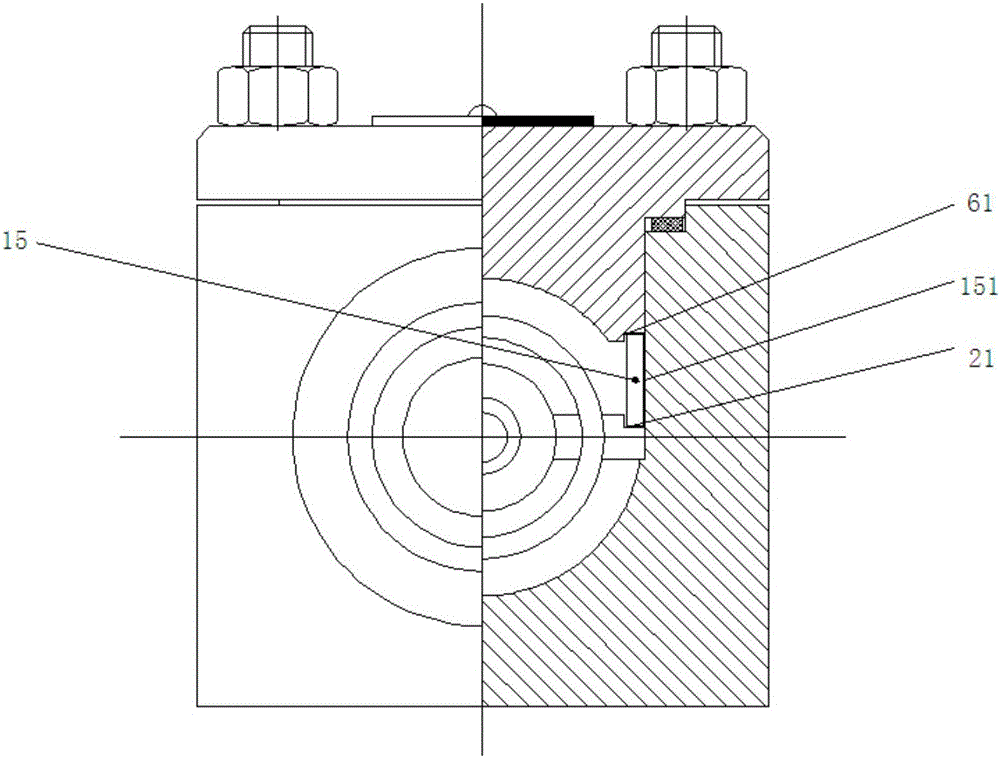

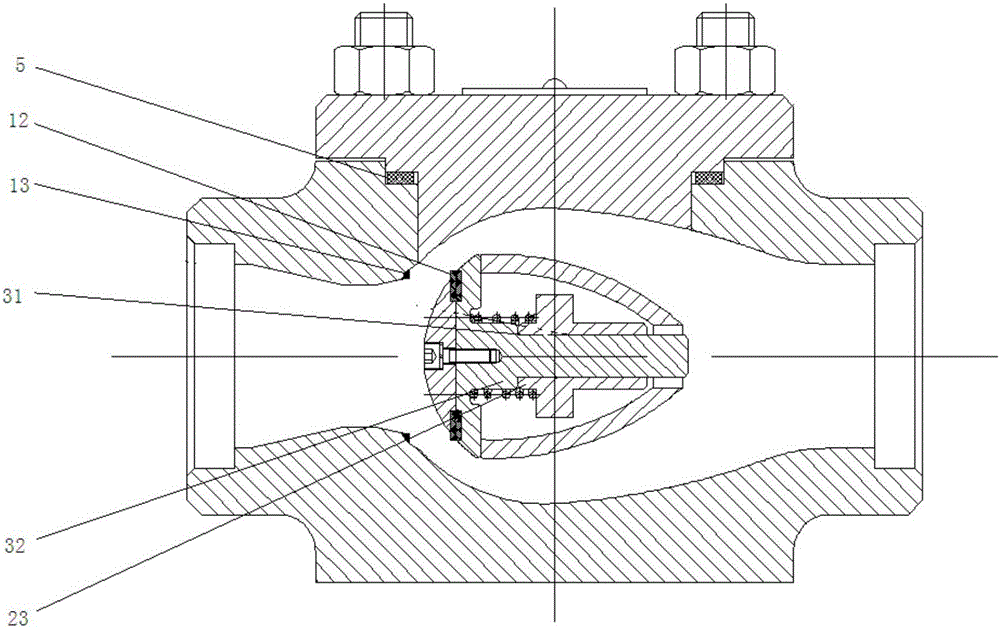

[0037] This embodiment provides an axial-flow check valve that can replace internal parts on-line, such as figure 1 As shown, it includes: a valve body 1, a valve cover 6 located on the upper part of the valve body 1, and a valve disc assembly arranged in the middle cavity of the valve body 1. The valve cover 6 and the valve body 1 are connected by a sealing structure and a detachable fastening structure. A valve flap positioning assembly for positioning the valve flap assembly is also arranged in the cavity of the valve body 1 , and the valve flap positioning assembly is fixedly installed on the wall of the cavity of the valve body 1 .

[0038] In the axial flow check valve of this embodiment, the internal parts of the valve body 1 can be maintained online by removing the valve cover 6 located on the upper part of the valve body 1 . The disc assembly in the cavity of the valve body 1 is directly fixed on the wall of the cavity of the valve body 1, instead of being fixed by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com