Multilayer nested cavitator capable of forming large-range cavitation

A cavitation, nested technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low energy utilization rate, limited instantaneous action range and small area volume and other problems, to achieve the effect of improving the degradation rate and sterilization efficiency, considerable cavitation effect, and enhancing cavitation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

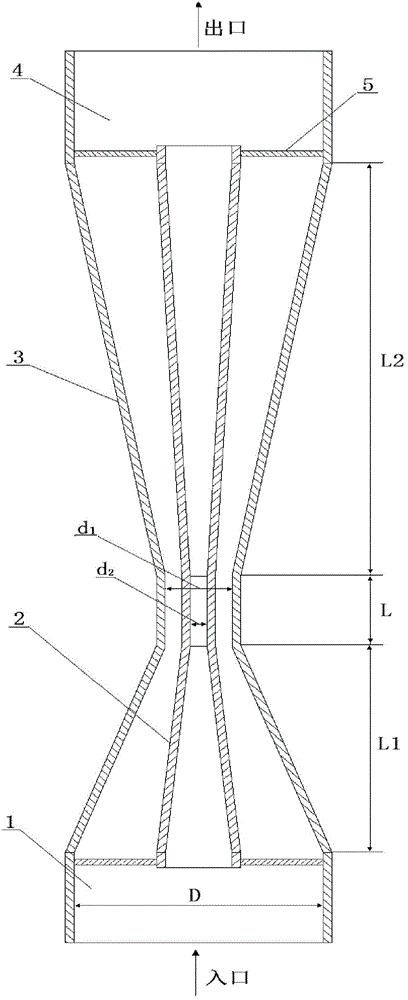

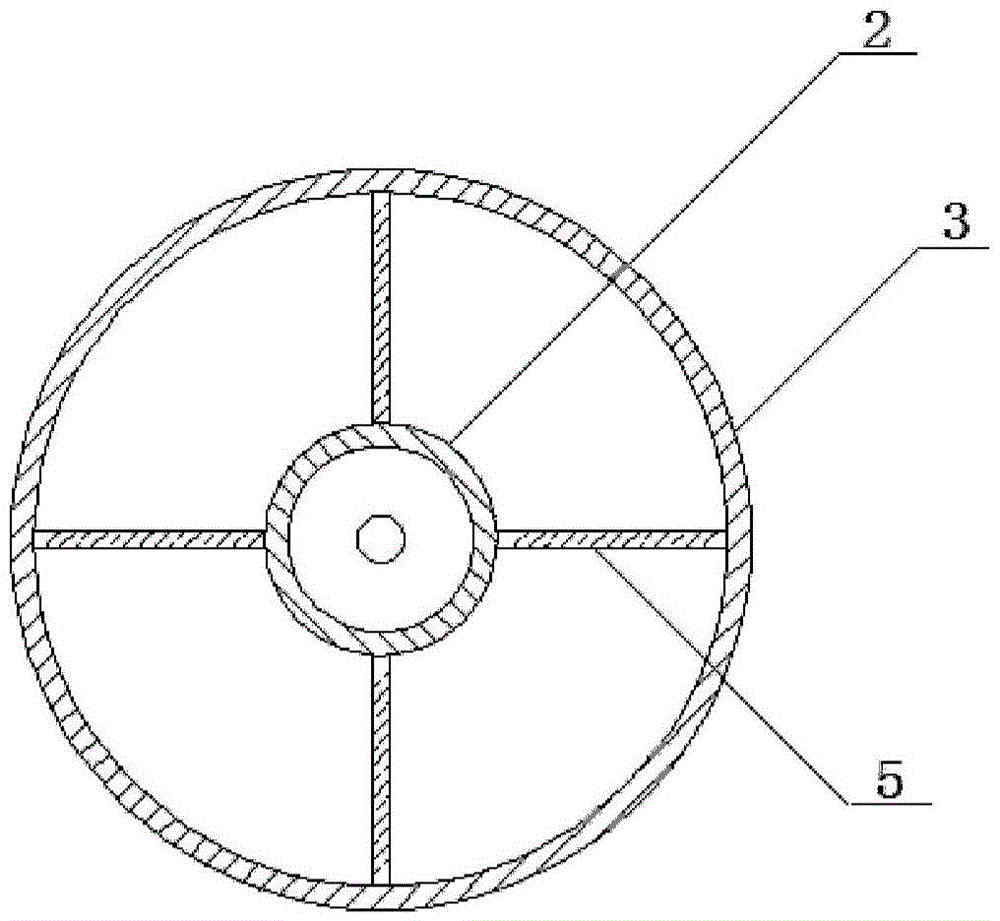

[0022] Such as figure 1 and figure 2 As shown, the multi-layer nested cavitator capable of forming a wide range of cavitation in the present invention includes: an inlet section 1, an inner Venturi cavitator 2, an outer Venturi cavitator 3, and an outlet section 4 and supporting structures 5 .

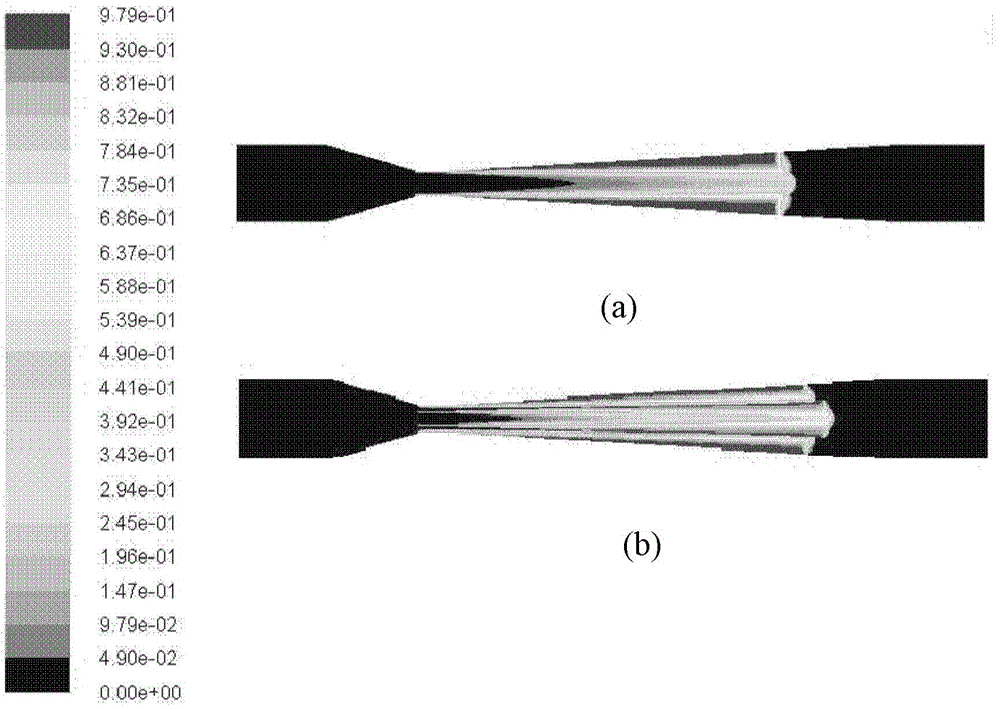

[0023] The end of the inlet section 1 is radially provided with a supporting structure 5 (such as figure 2 As shown), the support structure is four support cylinders evenly distributed, and the inner Venturi cavitator 2 is supported by the four support cylinders. The fluid enters from the inlet section 1, and enters the inner Venturi cavitator at the same time according to the flow distribution 2 and its gap with the outer Venturi cavitator 3. The inner Venturi cavitator 2 and the outer Venturi cavitator 3 form a coaxial ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com