Synchronous rotary compressor

A compressor and rotary technology, applied in the field of compressors, can solve the problems of high machining accuracy, short life of wearing parts, poor reliability, etc., and achieve the effects of reducing flow resistance loss, smooth machine operation, and reducing friction and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

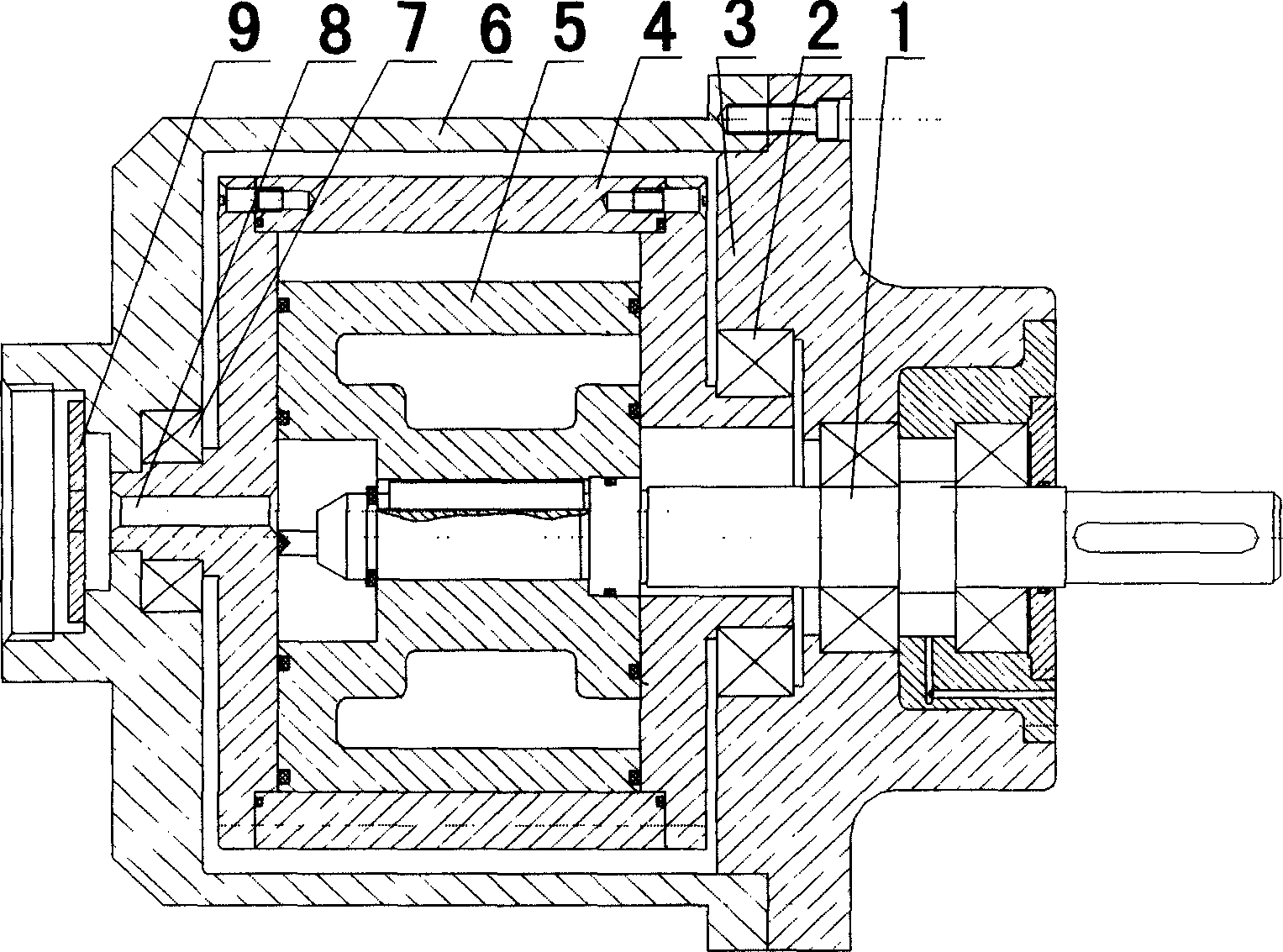

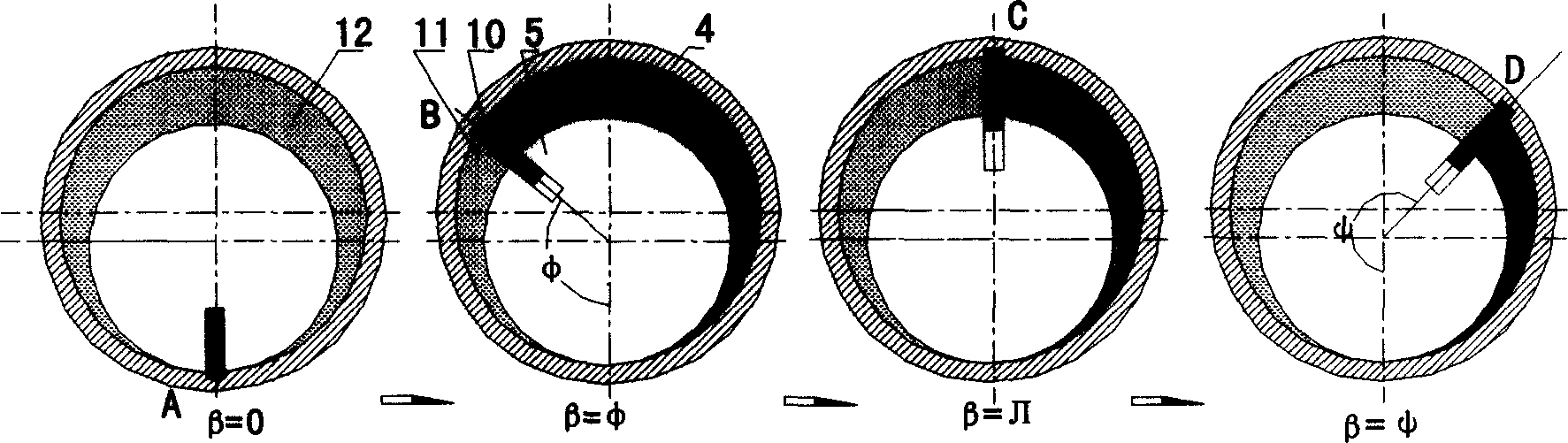

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] see figure 1 , the present invention includes a cylinder 4 and a rotor 5 set in the cylinder 4 and set on the drive shaft 1, a slide plate 10 that can be embedded in the cylinder 4 is also provided on the rotor 5, and the cylinder 4 that can rotate with the rotor 5 passes through the frame bearing 7 Installed on the fixed frame 6, the fixed frame 6 is also provided with an exhaust valve 9 communicating with the exhaust hole 8 of the cylinder, and the cylinder 4 is concentric with the fixed frame 6, and is not on the same axis as the rotor 5 The fixed frame 6 is installed on the eccentric seat 3 through the support bearing 2 . When the drive shaft 1 rotates, it drives the rotor 5 to make a complete rotary motion, and the slide plate 10 is embedded in the cylinder 4 under the action of centrifugal force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com