Swing rotor compressor

A rotor compressor and rotor technology, applied in the field of rotary compressors, can solve the problems of poor movement of valve plates, mechanical noise, air flow pulsation, etc., and achieve the effect of improved durability and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

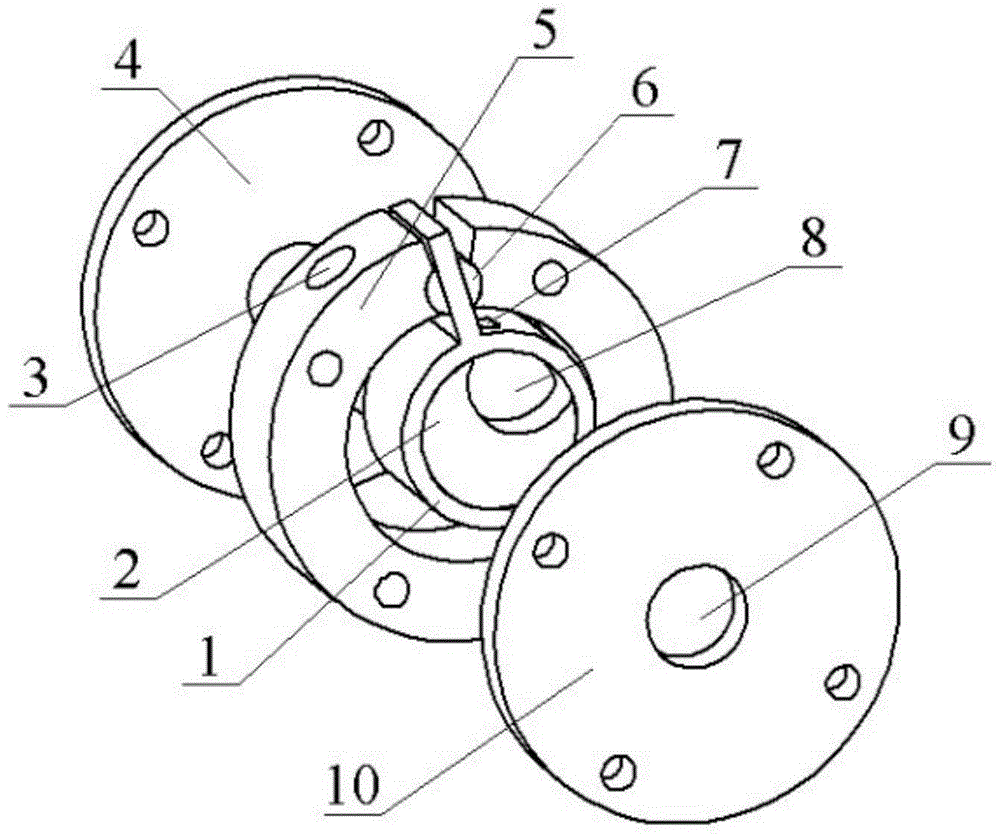

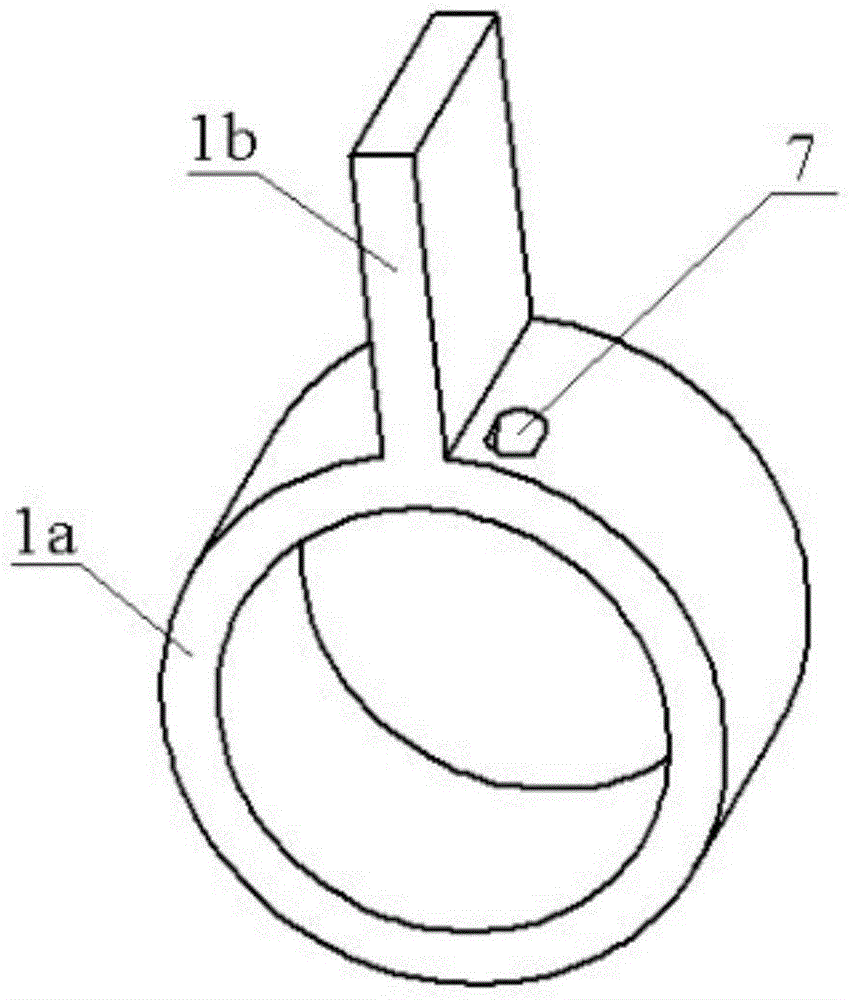

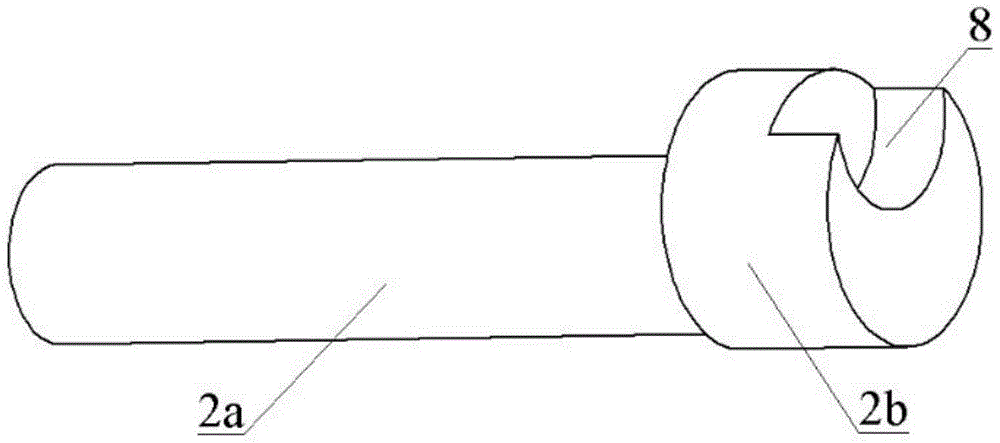

[0024] figure 1 A swing rotor compressor shown includes a swing rotor 1 , an eccentric shaft 2 , a front end cover 4 , a cylinder 5 , a guide rail 6 and a rear end cover 10 . figure 1 The structure of the middle swing rotor 1 is as follows figure 2 , figure 2 The oscillating rotor shown comprises a roller ring 1a and a oscillating link 1b. figure 1 The structure of the center eccentric axle 2 is as follows: image 3 , image 3 The shown eccentric shaft comprises a main shaft 2a and an eccentric 2b.

[0025] figure 1 Among them, the swing rotor 1 is housed in the cylinder 5 . The rolling ring of the oscillating rotor 1 is sleeved on the eccentric wheel of the eccentric shaft 2 , and the main shaft rotation center of the eccentric shaft 2 coincides with the geometric center of the cylinder 5 . The swing rod of the swing rotor 1 can freely slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com