Combined high pressure air exhaust valve

An exhaust valve, high-pressure technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problems of many connecting pipes in the drying system, unreliable high-pressure one-way sealing, large gas flow loss, etc., and achieve the sealing effect. Good, simple structure, reducing the effect of pipeline connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

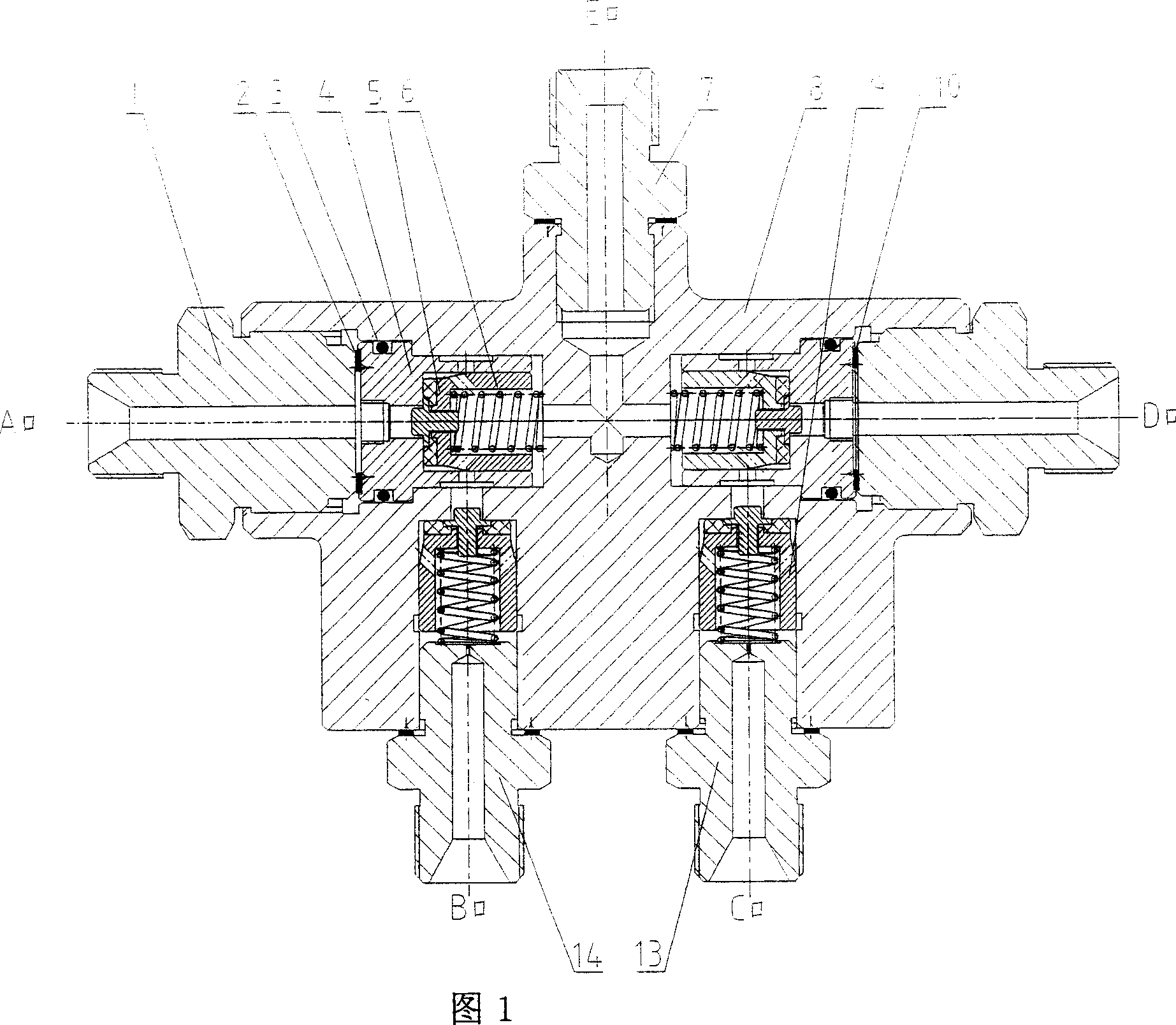

[0016] The present invention mainly consists of a joint body 1, a gasket 2, an O-ring 3, a valve seat 4, a valve core assembly 5, a spring 6, a joint body 7, an exhaust valve body 8, a valve core assembly 9, a gasket 10, and a one-way sealing valve. 11, 12, 15, 16, throttling valves 13, 14 and so on.

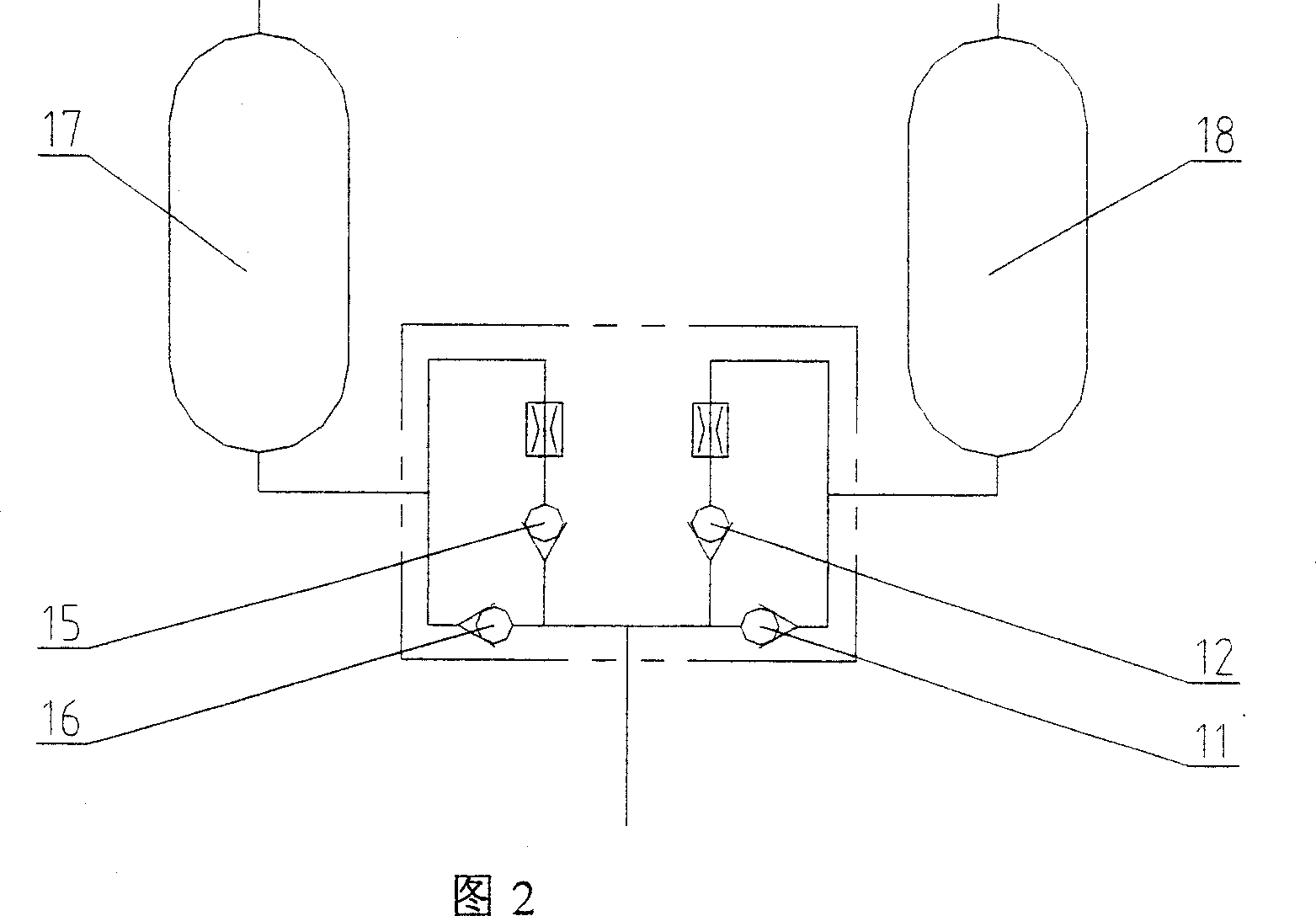

[0017] The present invention mainly installs four sets of one-way sealing valves 16, 15, 11, 12 and two sets of throttle valves 13, 14 respectively in the inner cavity of the exhaust valve body 8, and correspondingly configures 5 ports, respectively A ports, B port, C port, D port, E port. The specific structure is that a three-way gas channel is provided at the center of the exhaust valve body 8, a one-way sealing valve 16 and a one-way sealing valve 11 are respectively arranged at both ends of the straight channel, and a joint 7 is installed in the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com