Energy-saving type refrigeration and dehumidification integrated machine

An all-in-one machine and condenser technology, applied to refrigerators, compressors, refrigeration components, etc., can solve problems such as uneven pressure behind the valve, energy consumption, and potential safety hazards, and achieve improved dehumidification capacity, reduced heat supplement demand, and energy saving significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

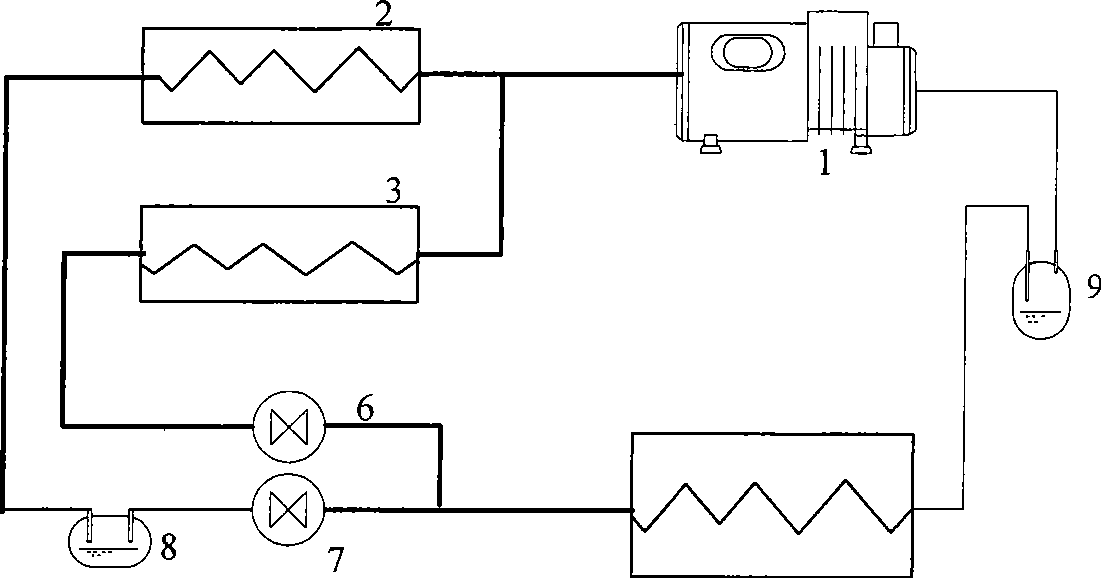

Embodiment 1

[0024] The energy-saving type refrigeration and dehumidification integrated machine of embodiment 1, its structure is as follows figure 1 As shown, it includes: a compressor 1, an outdoor condenser 2, a liquid accumulator 8, a first electronic expansion valve 7, an evaporator 4, and a gas-liquid separator 9 that are sequentially connected and form a refrigeration circuit; and are sequentially connected to the output of the compressor 1 The indoor condenser 3 and the second electronic expansion valve 6 at the input end of the evaporator 4; the outdoor condenser 2, the indoor condenser 3 and the regenerator 5 are equipped with fans;

[0025] A second liquid accumulator 10 may also be installed on the connecting pipeline between the indoor condenser 3 and the first electronic expansion valve 6;

[0026] When there is a demand for cooling, the device enters the cooling mode, and the second electronic expansion valve 6 is closed; when there is a demand for heating or constant temp...

Embodiment 2

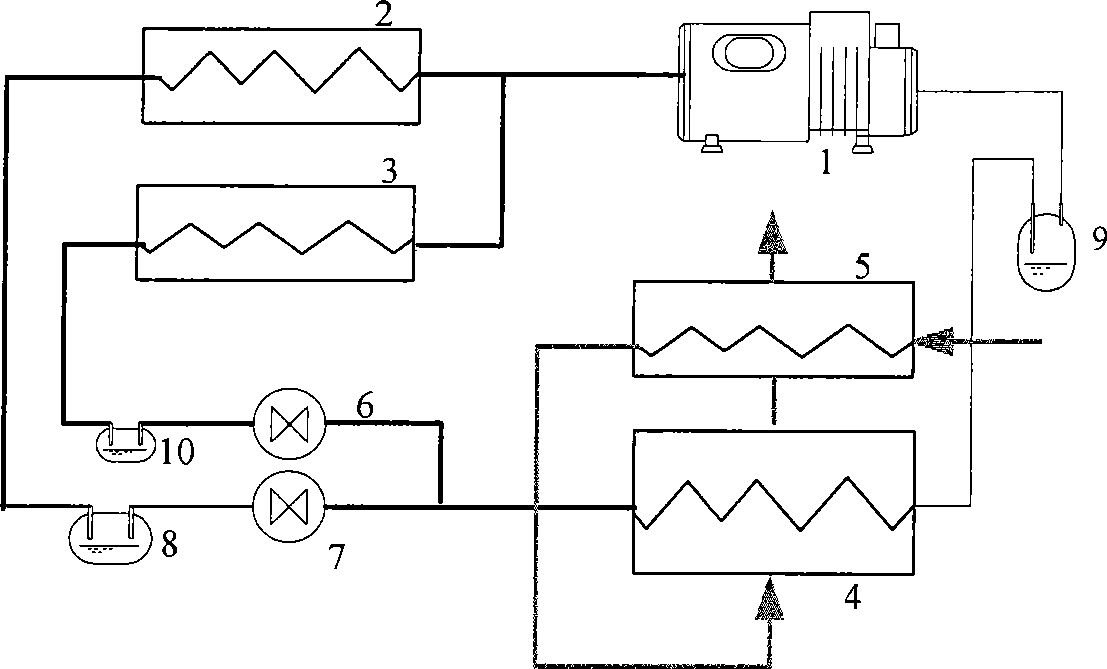

[0028] The energy-saving integrated refrigeration and dehumidification machine of embodiment 2 has a structure such as figure 2 As shown, the energy-saving refrigeration and dehumidification integrated machine includes:

[0029] It includes: a compressor 1, an outdoor condenser 2, a liquid receiver 8, a first electronic expansion valve 7, an evaporator 4, and a gas-liquid separator 9 that are connected in sequence to form a refrigeration circuit; and are sequentially connected to the output end of the compressor 1 and the evaporation The indoor condenser 3 and the second electronic expansion valve 6 at the input end of the device 4; the outdoor condenser 2, the indoor condenser 3 and the regenerator 5 are equipped with fans;

[0030] The difference from Embodiment 1 is that it also includes a regenerator 5, the air inlet of the indoor condenser 3 communicates with the room; the fresh air inlet and the old air outlet of the regenerator 5 communicate with the room, and the The...

Embodiment 3

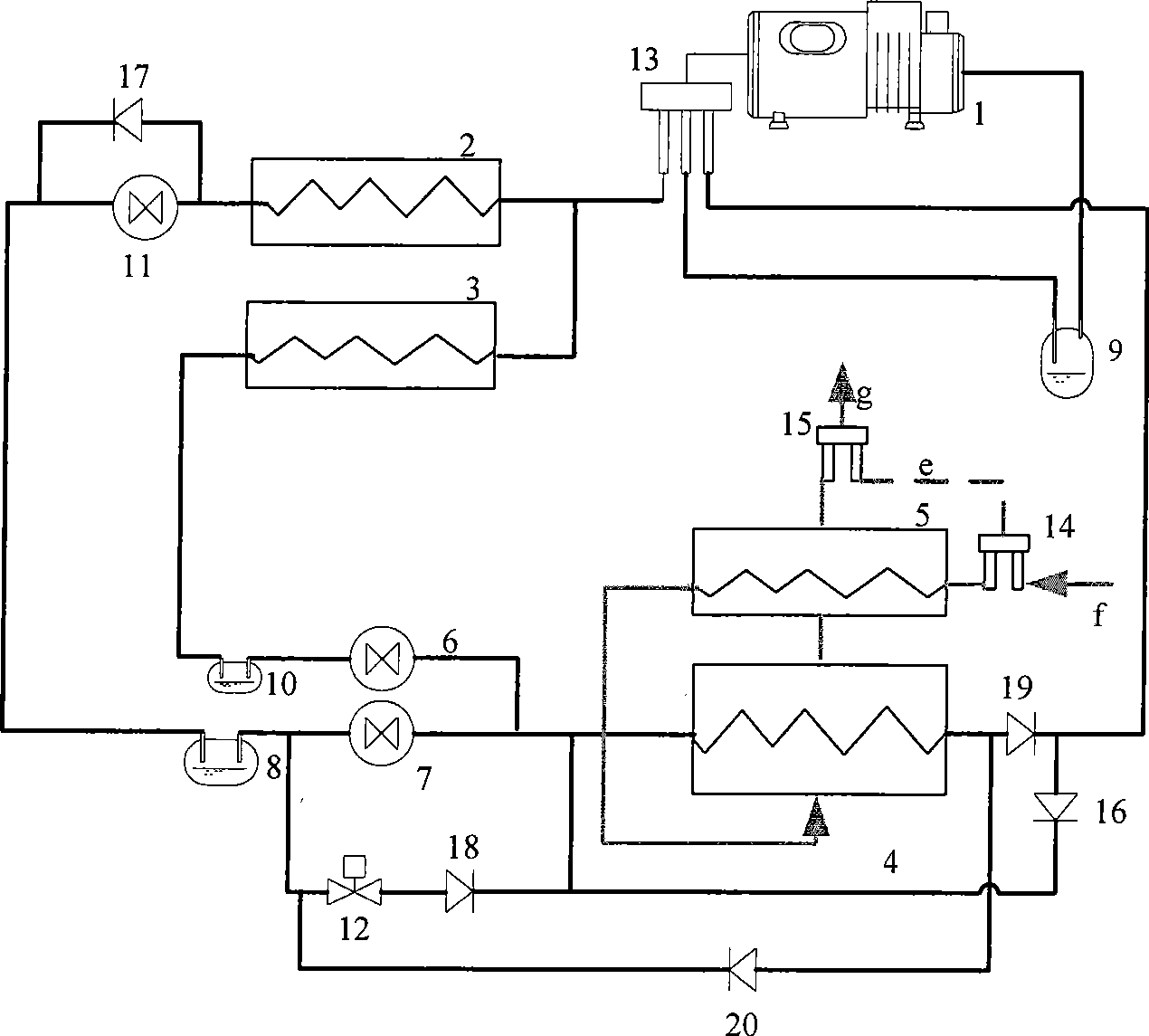

[0034] 1. The structure of the energy-saving integrated refrigeration and dehumidification machine in Example 3 is as follows: image 3 As shown, the difference is that: the technology of embodiment 2 is increased: four-way valve 13, heat pump electronic expansion valve 11, solenoid valve 12, first one-way valve 16, second one-way valve 17, third one-way valve 18. The fourth one-way valve 19, the fifth one-way valve 20, the first three-way valve 14 and the second three-way valve 15;

[0035] The four-way valve 13 is installed at the output end of the compressor 1, and is connected with the gas-liquid separator 9, the evaporator 4 and the outdoor condenser 2 at the same time;

[0036] The solenoid valve 12 and the third one-way valve 18, the first one-way valve 16 and the fourth one-way valve 19 are sequentially connected in series to the bypass between the outlet of the liquid reservoir 8 and the outlet of the evaporator 4 on the connecting pipe;

[0037] The heat pump elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com