High-power pulse tube refrigerator based on Stirling refrigerator

A pulse tube refrigerator, high-power technology, applied in refrigerators, gas cycle refrigerators, refrigeration components, etc., can solve the problems of not eradicating the inhomogeneity of the regenerator, restricting reliability, cold end vibration, etc. Reliability and application range, overcoming flow non-uniformity issues, reducing vibration and motion wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

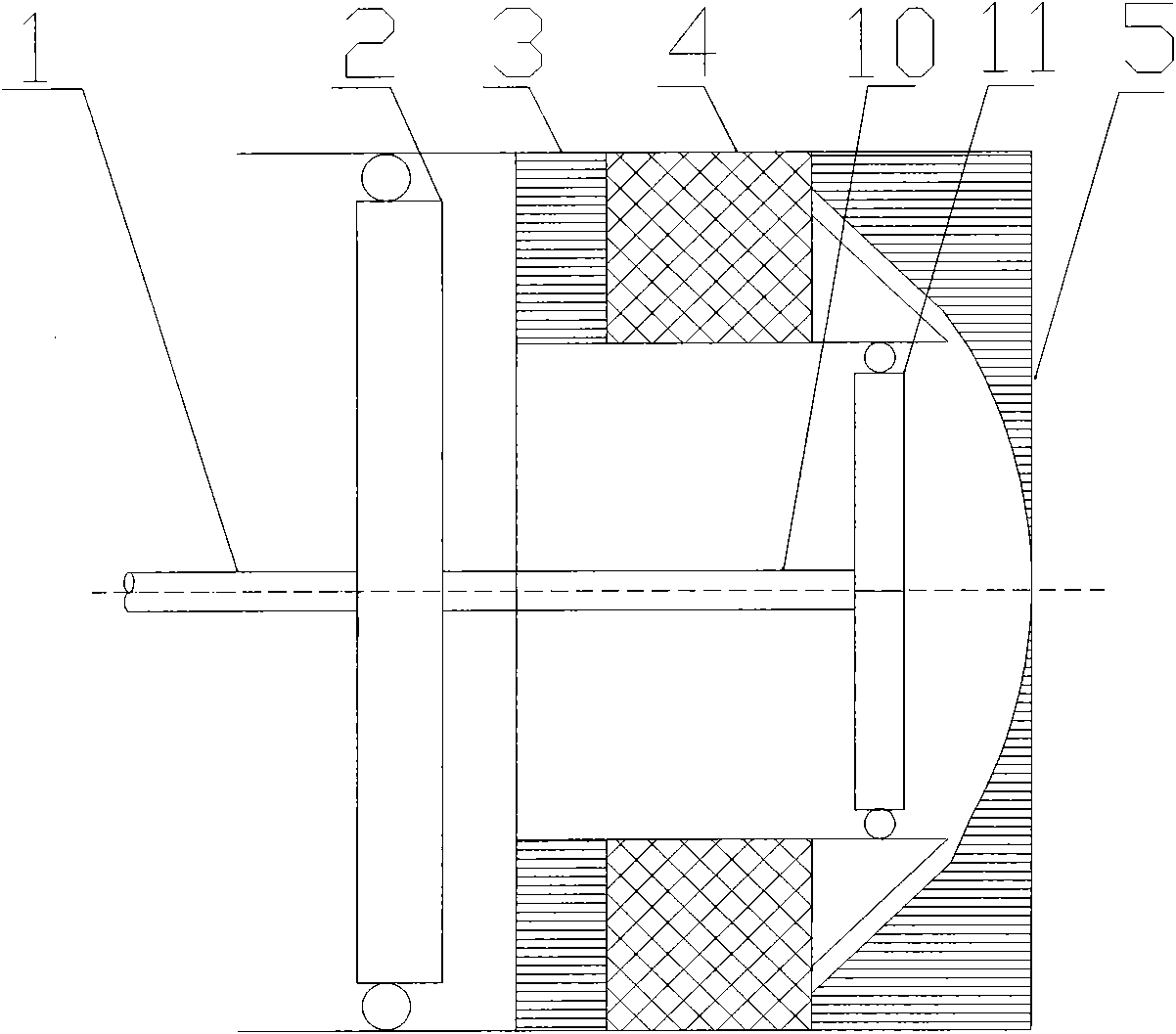

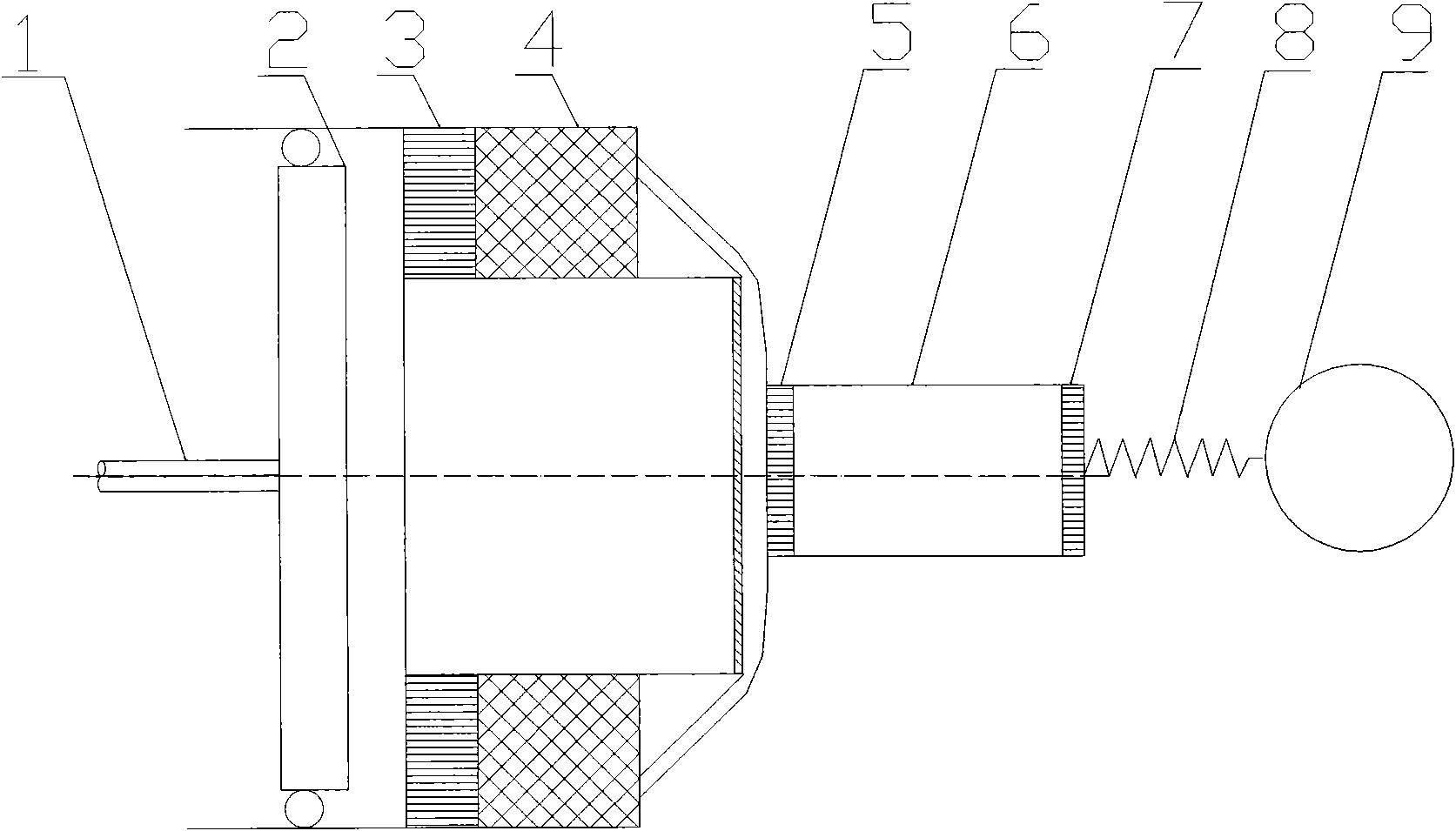

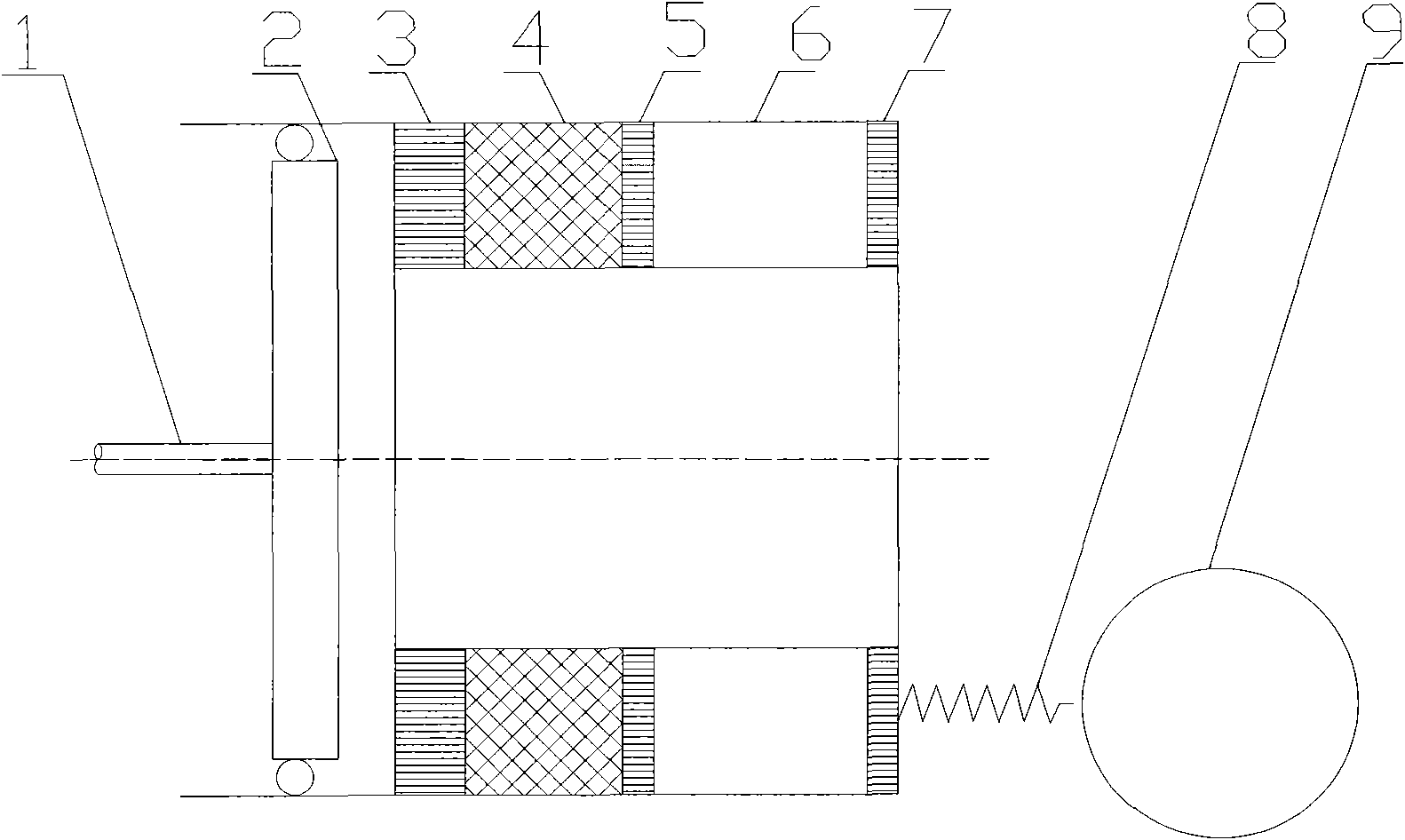

[0013] like figure 2 , image 3 As shown, a high-power pulse tube refrigerator based on a Stirling refrigerator includes a crank connecting rod 1, a compression piston 2, a water cooler 3, a regenerator 4, a cold end heat exchanger 5, a pulse tube 6, and a hot end heat exchanger Device 7, inertia tube 8, gas storage 9, piston rod 1 pushes compression piston 2 to communicate with regenerator 4 through water cooler 3, and then communicates with pulse tube 6, and two ends of pulse tube 6 are respectively equipped with hot end heat exchangers 7 And the cold end heat exchanger 5, the hot end heat exchanger 7 communicates with the gas storehouse 9 through the inertia tube 8.

[0014] The regenerator 4 is an annular regenerator. The water cooler 3 is an annular water cooler. Vessels are round or annular.

[0015] The present invention retains the auxiliary connecting rod 1, the compression piston 2, the water cooler 3 and the regenerator 4 of the original Stirling refrigerator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com