Active-regeneration type thermoelastic refrigeration system

A technology of active regenerative and cooling systems, applied in heating and cooling combinations, refrigerators, refrigeration components, etc., can solve the problem of single-stage elastic-thermal refrigeration cycles and systems that are difficult to meet large system temperature differences, cannot be guaranteed, large system temperature differences, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

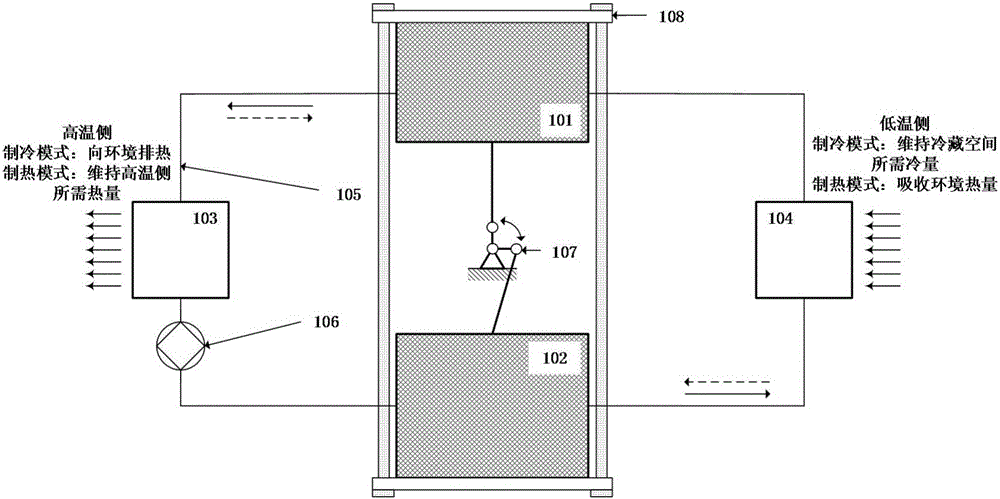

[0050] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

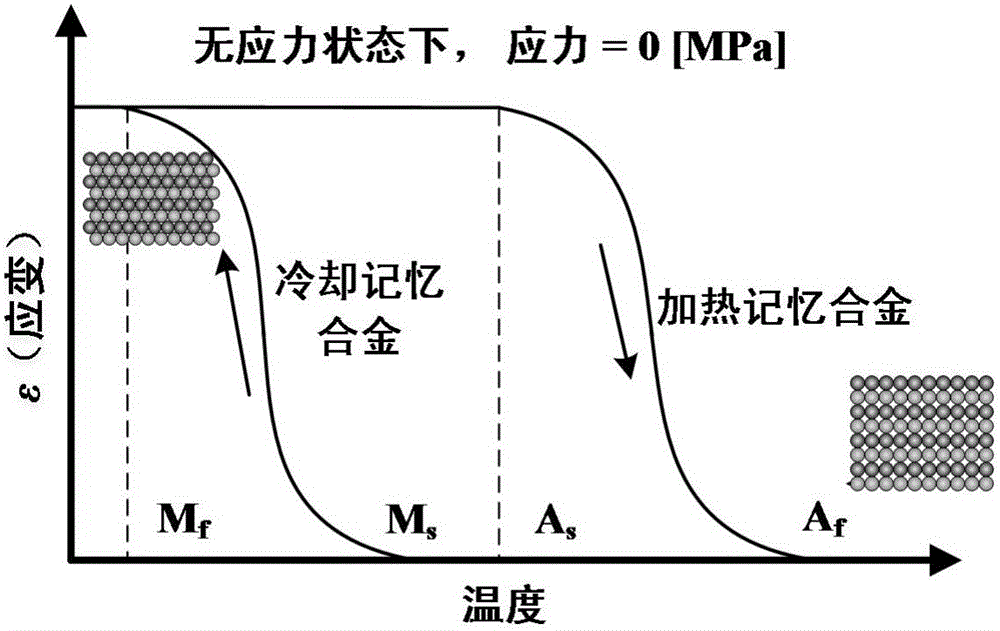

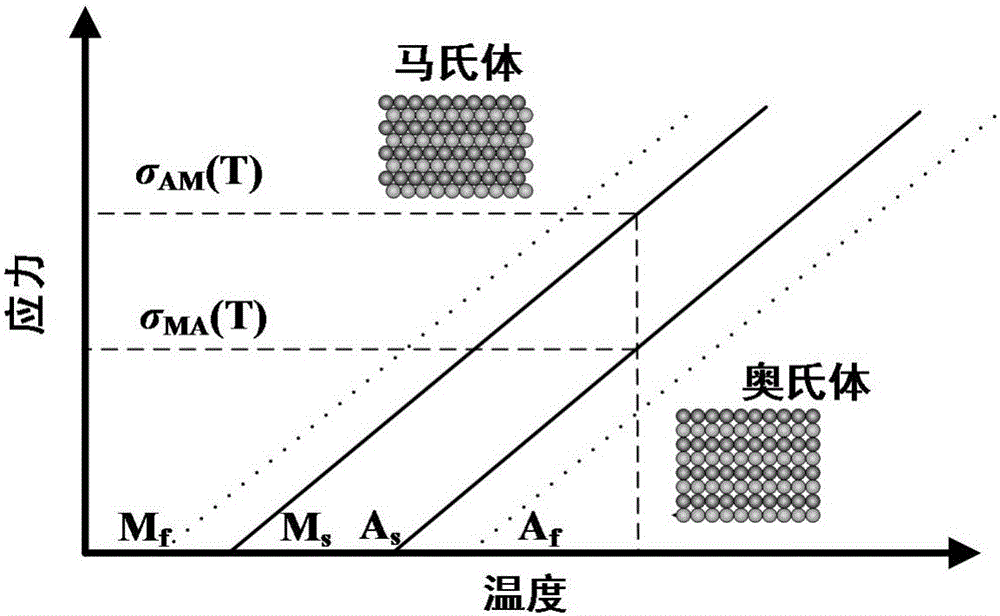

[0051] The invention is aimed at the solid-state refrigeration technology using shape memory alloy (short for memory alloy) martensitic phase transformation refrigeration and heating. In shape memory alloys, there are at least two crystal structures (phases), most typically a high temperature phase (austenite) and a low temperature phase (martensite). Such as Figure 1A As shown, when the high temperature phase is stress-free, when the material temperature is higher than A f When the stable component, the content of martensitic phase is the lowest at this time; the temperature of the material is lowered to M s , the austenite in the high-temperature phase begins to transform into martensite in the low-temperature phase, and releases latent heat at the same time; when the material temperature is lower than M f , martensite becomes a stable comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com