Recuperative heat exchanger with radial reinforced heat conduction

A recuperative heat exchanger and regenerator technology, which is applied in the direction of superheater, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problem of insufficient radial heat conduction capacity, etc., to maintain temperature consistency and reduce temperature difference , the effect of convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

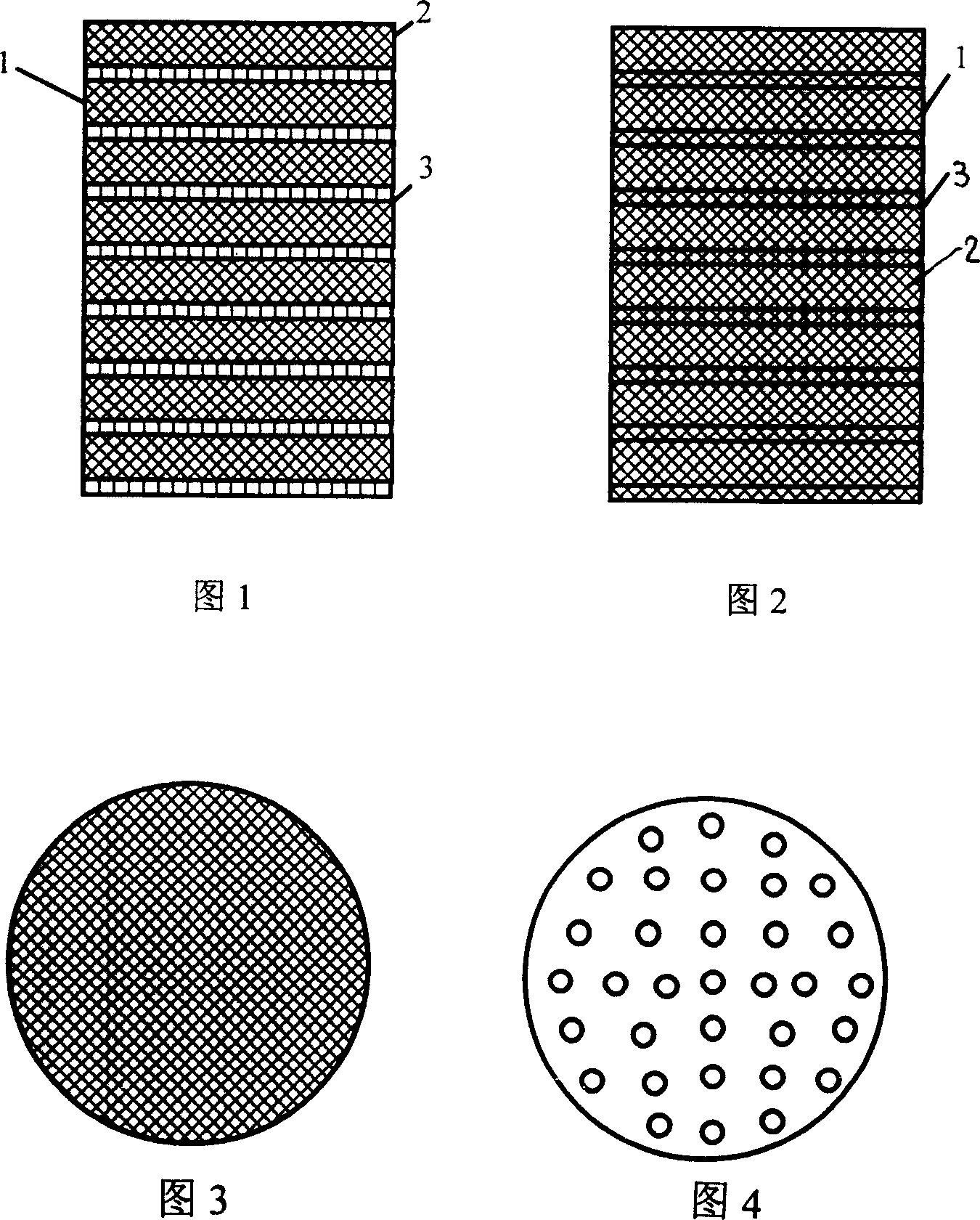

[0025] Fig. 1 is a regenerative heat exchanger with radially enhanced heat conduction formed by interlacing metal plates 3 with holes and stainless steel wire mesh 2 filled into the shell 1 of the regenerator. The outer diameter of the perforated metal plate 3 is consistent with the inner diameter of the regenerator shell 1 . The hydraulic diameter of the small holes in the metal plate with holes 3 is 1mm, 3 or 5mm, which can be determined according to needs; The thickness of the metal plate is in the range of 1-10mm, which can be determined according to the needs; as long as the filling amount of the stainless steel wire mesh is greater than that of the metal plate with holes.

Embodiment 2

[0027] Fig. 2 is a regenerative heat exchanger with radially enhanced heat conduction formed by interlacing grid-like metal plates 3 and stainless steel wire mesh 2 into the regenerator shell 1. The outer diameter of the mesh metal plate 3 is consistent with the inner diameter of the regenerator shell 1 . The hydraulic diameter of the grid in the grid-shaped metal plate is 0.5mm, which can be determined according to the needs; The thickness of the grid-shaped metal plate 3 is in the range of 1-10 mm, which can be determined according to the needs; as long as the filling amount of the stainless steel wire mesh is greater than that of the grid-like metal plate.

[0028] In short, the metal plate with holes used in the regenerative heat exchanger with radially enhanced heat conduction of the present invention may be copper, aluminum or silver metal plates with holes. The wire mesh can be phosphor bronze, magnetic metal or stainless steel wire mesh; lead balls can also be used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com