Refrigerant system possessing multi- speed cyclone compressor and economizer loop

A refrigerant system, scroll compressor technology, applied in irreversible cycle compressors, compressors, refrigerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

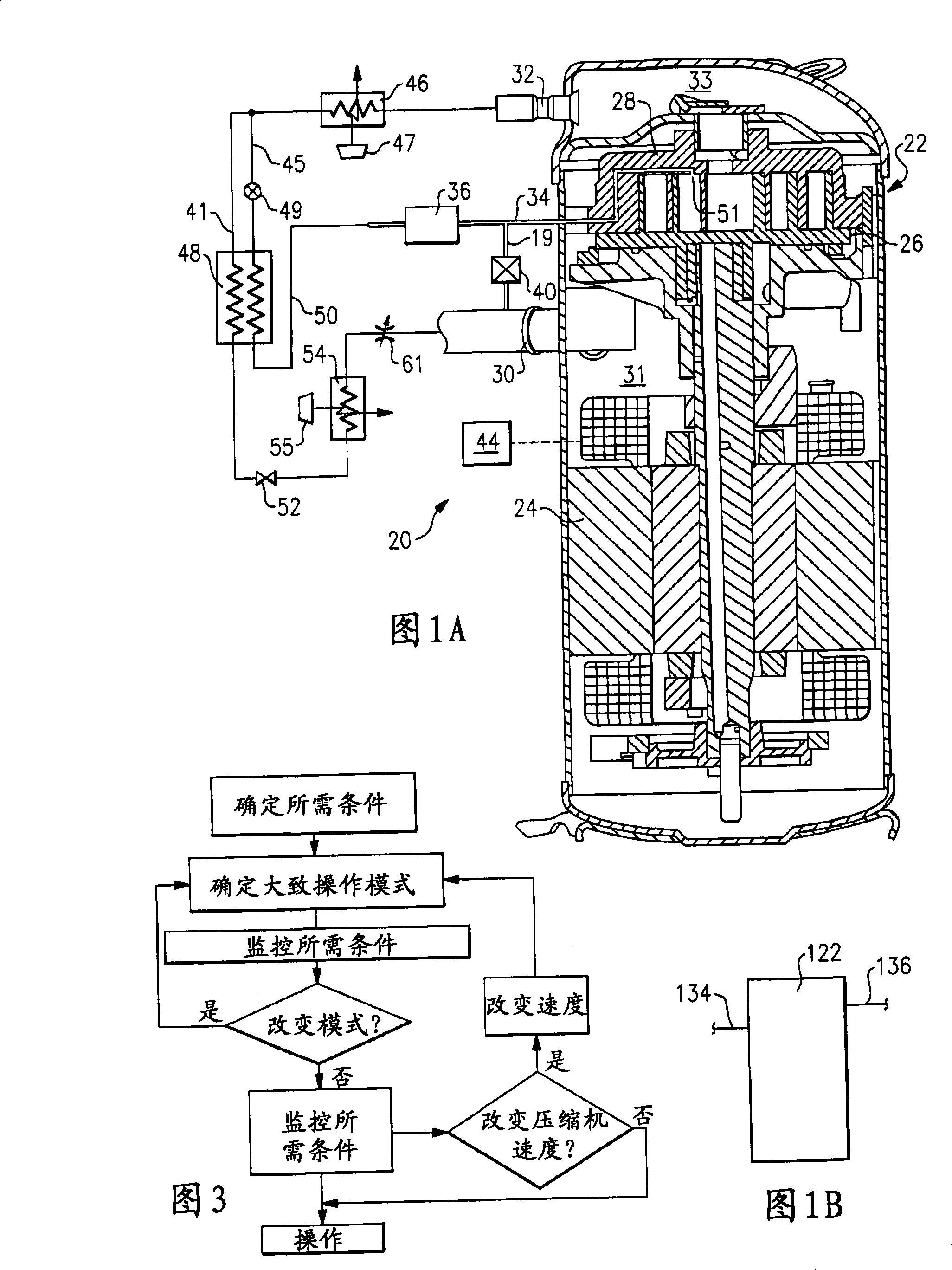

[0018] The refrigerant system 20 is shown in FIG. 1A , the refrigerant system 20 has a compressor 22 and a controller 44 . As is known, the motor 24 for the compressor 22 can be driven at two speeds so that the amount of refrigerant compressed by the compressor 22 and circulated throughout the system can be varied. That is, the compressor is driven at one of two non-zero speeds during steady state operation. The compressor 22 is a scroll compressor having an orbiting scroll member 26 and a non-orbiting scroll member 28 . As is known, a plurality of compression pockets are defined between the two scroll members, which compress entrained refrigerant when the orbiting scroll member 26 is driven to orbit by the motor 24 . It can be seen that the suction pipe 30 leads the refrigerant into the suction chamber 31 surrounding the motor and opening into the compression chamber. When the refrigerant is compressed, it is driven into the discharge chamber 33 which communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com