Patents

Literature

32results about How to "Increase unit cooling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

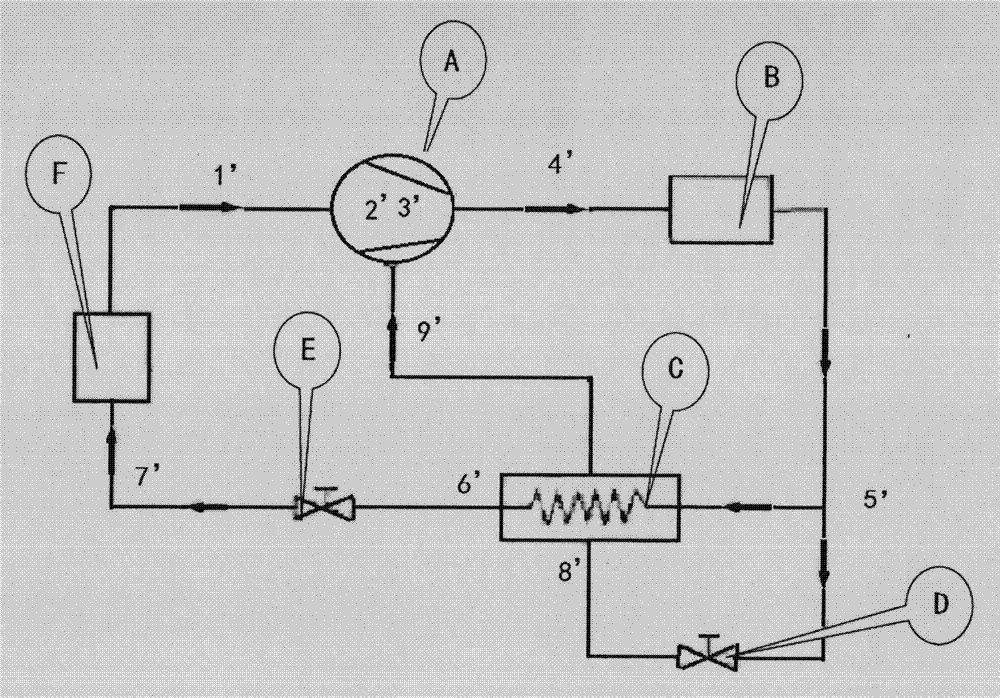

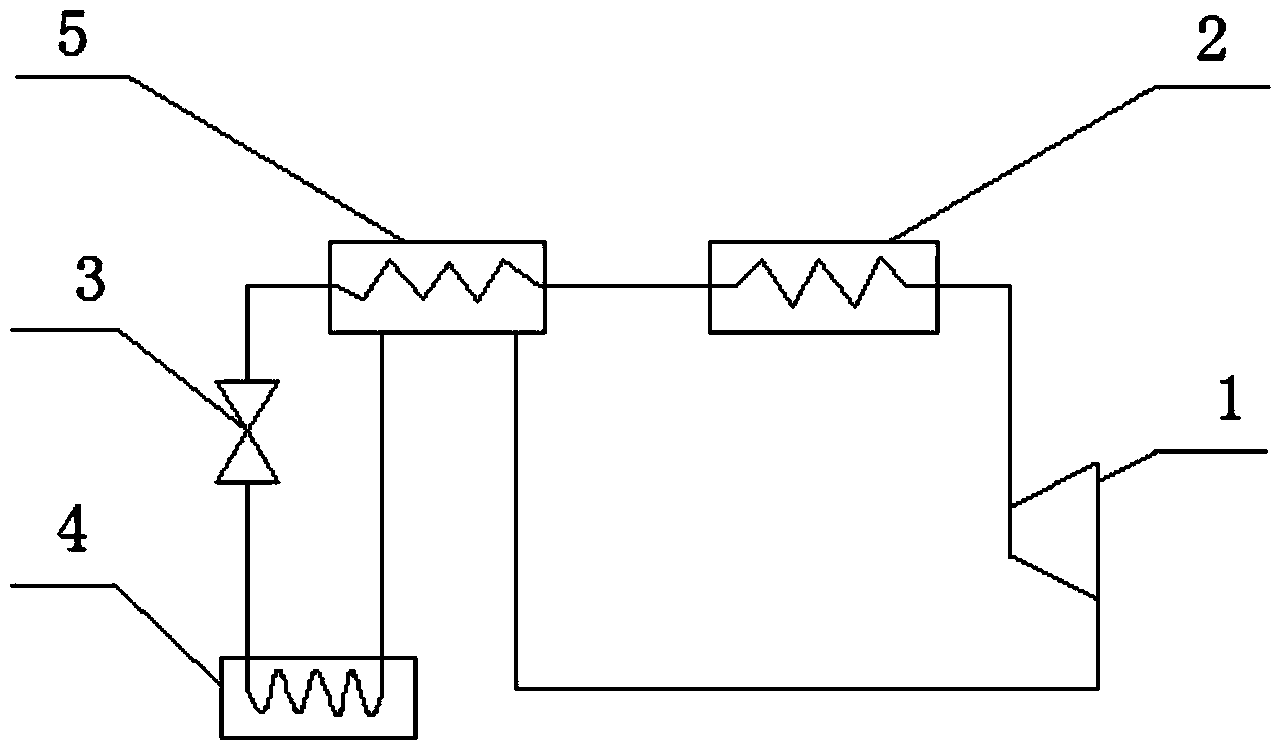

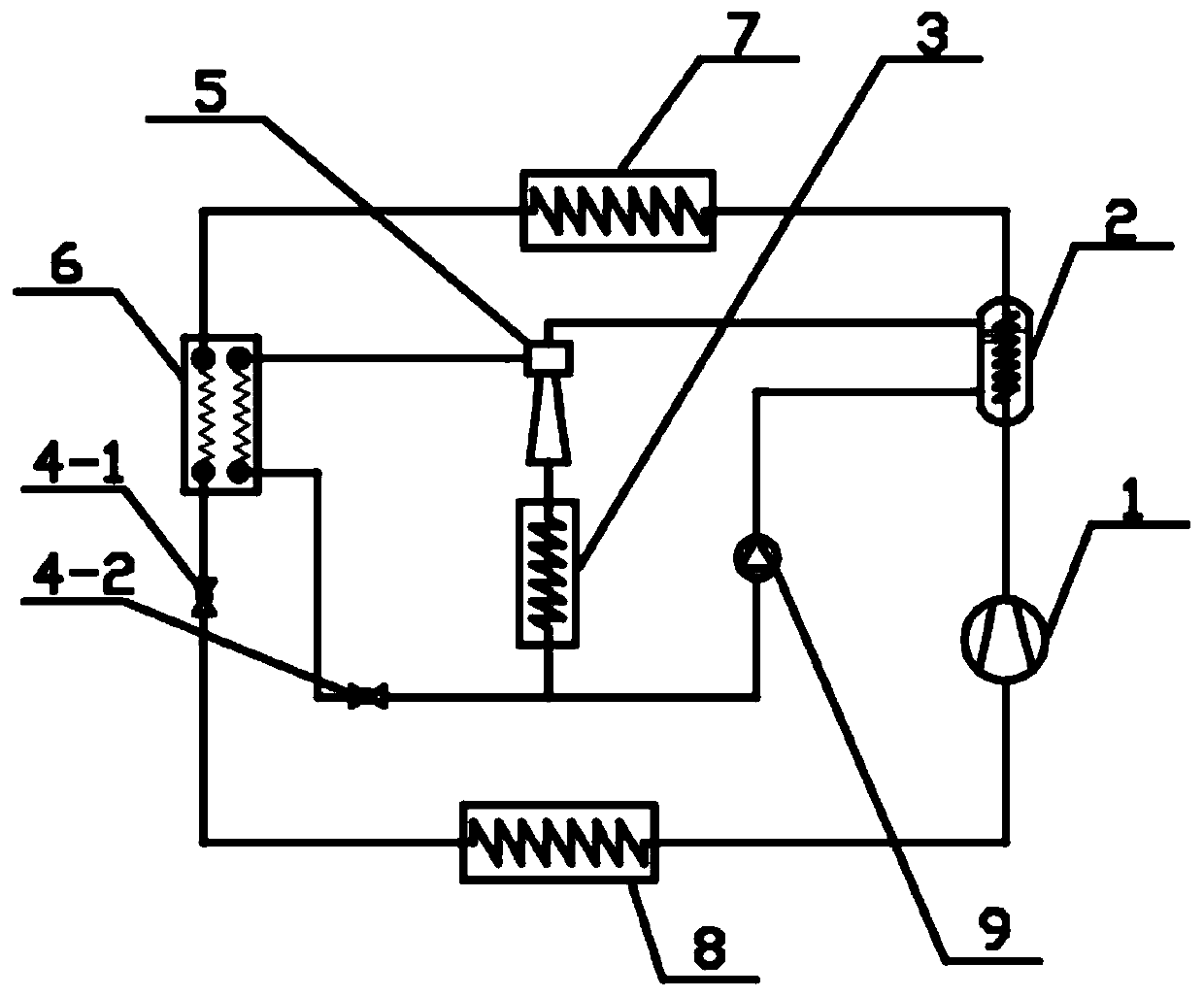

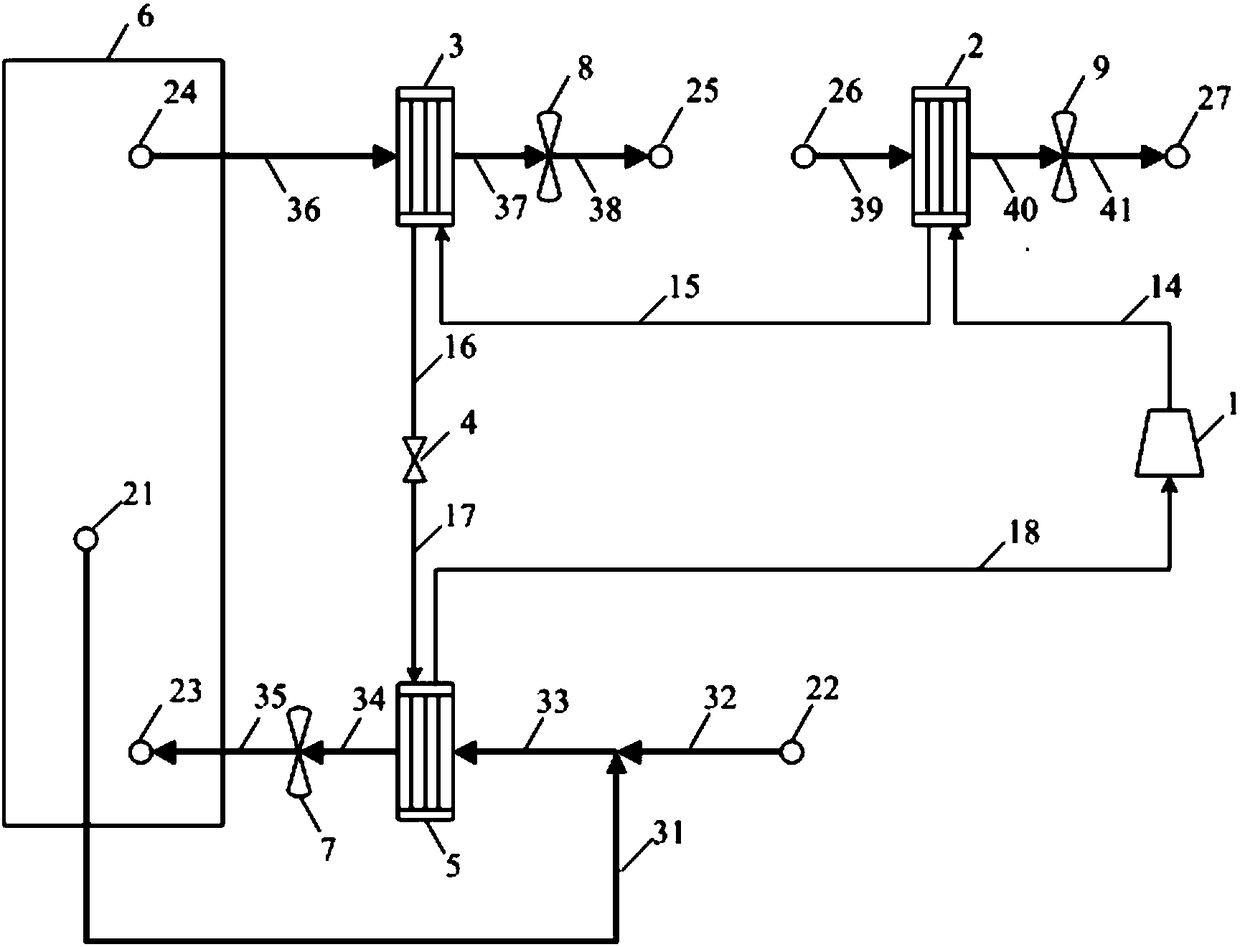

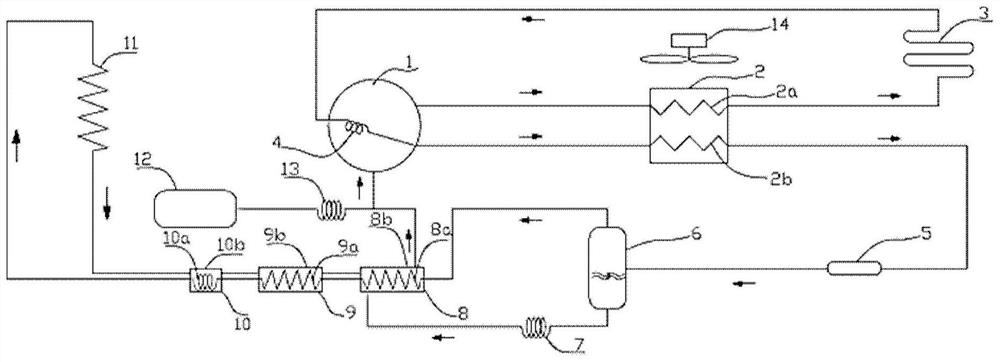

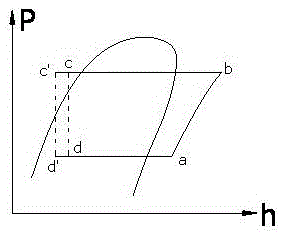

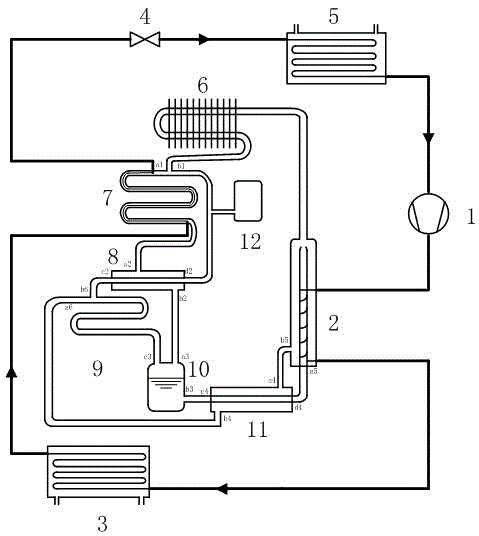

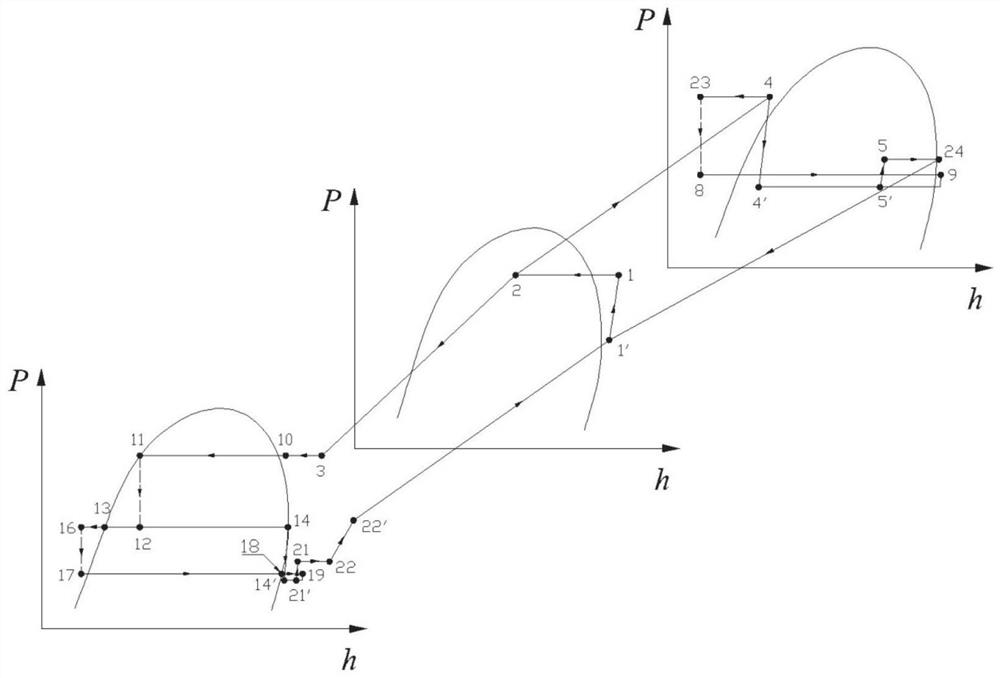

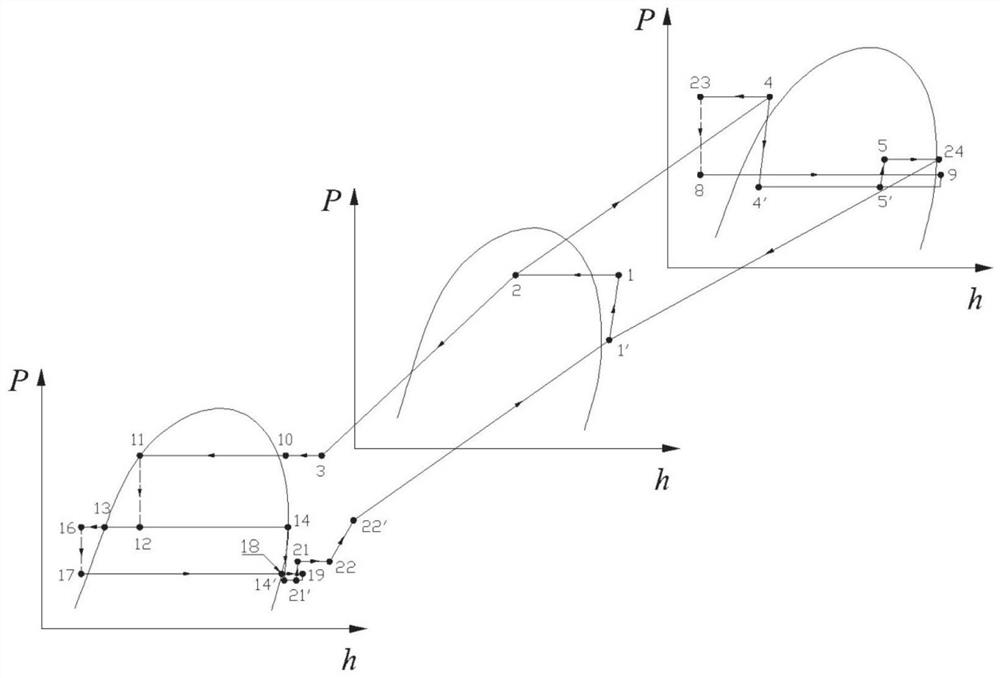

Device and method for combined ejection refrigeration and vapor compression refrigeration cycle

InactiveCN101825372AImprove the cooling factorImprove energy savingRefrigeration machinesEngineeringRefrigeration

The invention relates to a device and a method for the combined ejection refrigeration and vapor compression refrigeration cycle, aiming at improving the running efficiency of the refrigeration system and solving the problems that the unit power and the unit condensation rate of the compressor increase and the air transmission rate and the refrigeration coefficient decrease due to the regenerative cycle adopted in the vapor compression refrigeration cycle to make the refrigerant have a certain supercooling degree. On the vapor compression refrigeration cycle side, the air exhaust opening of a compressor (2) is connected with the refrigerant inlet of a generator (5), the refrigerant inlet of the generator (5) is connected with the inlet of a first condenser (3), the outlet of the first condenser (3) is connected with the refrigerant inlet of a supercooler (6), the refrigerant outlet of the supercooler (6) is connected with the refrigerant inlet of an evaporator (1) through a throttle valve (4), and the outlet of the evaporator (1) is communicated with the air suction opening of the compressor (2). The ejection refrigeration cycle and the vapor compression refrigeration cycle are combined in the device, and two refrigeration systems are connected through one generator and one supercooler.

Owner:SOUTHEAST UNIV

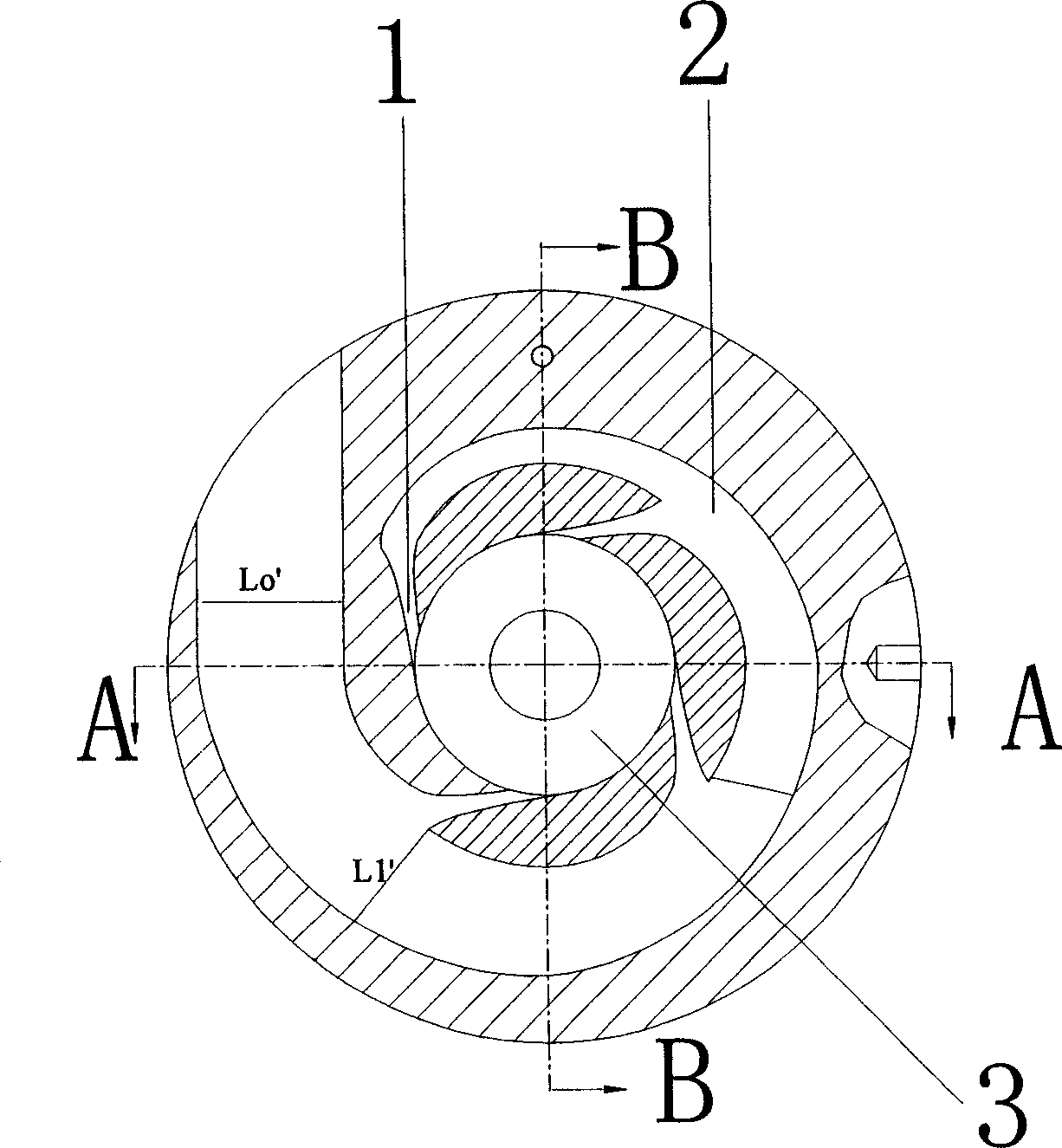

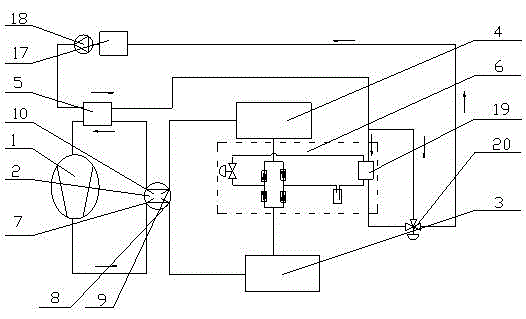

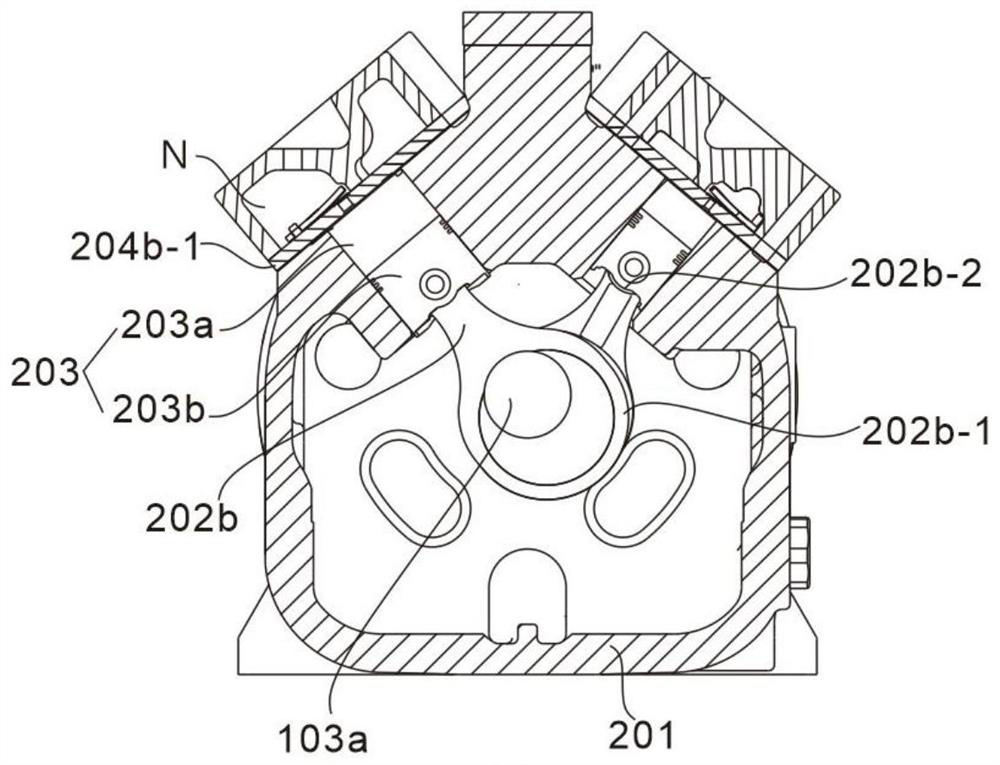

Efficient electric cold and warm air heat exchange system used for vehicle

ActiveCN103591733AReduce exhaust temperatureLarge displacementCompressorMechanical apparatusEngineeringElectronic expansion valve

The invention relates to an efficient electric cold and warm air heat exchange system used for a vehicle. The efficient electric cold and warm air heat exchange system comprises a vortex motor compressor, a heat exchanger outside the vehicle, a heat exchanger inside the vehicle and an economizer. An auxiliary suction port is formed in the vortex motor compressor, refrigerating fluid flows out of the heat exchanger outside the vehicle and then is divided into two paths, the refrigerating fluid in the first path is subject to heat exchanging, then is subject to undercooling, enters the heat exchanger inside the vehicle through an electronic expansion valve and finally is sucked through an air suction port of the vortex motor compressor. The refrigerating fluid in the second path enters the economizer through an electronic expansion valve and is changed to be gas after the refrigerating fluid is cooled in the first path and finally enters the vortex motor compressor through the auxiliary suction port. The heat exchange system can effectively solve the problems that under the working condition of low temperature, heating is not sufficient, and exhaust temperature of the compressor is too high.

Owner:江苏晨宇科技有限公司

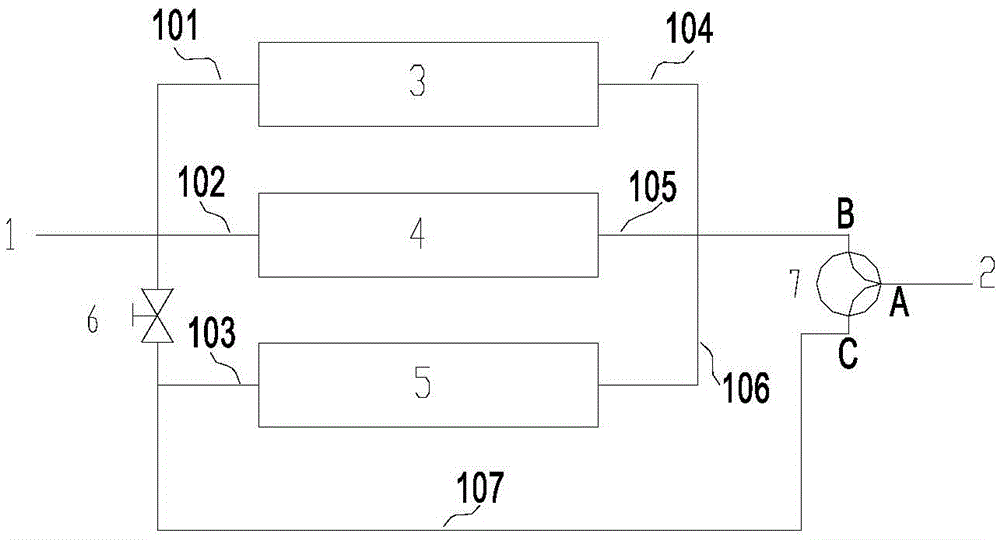

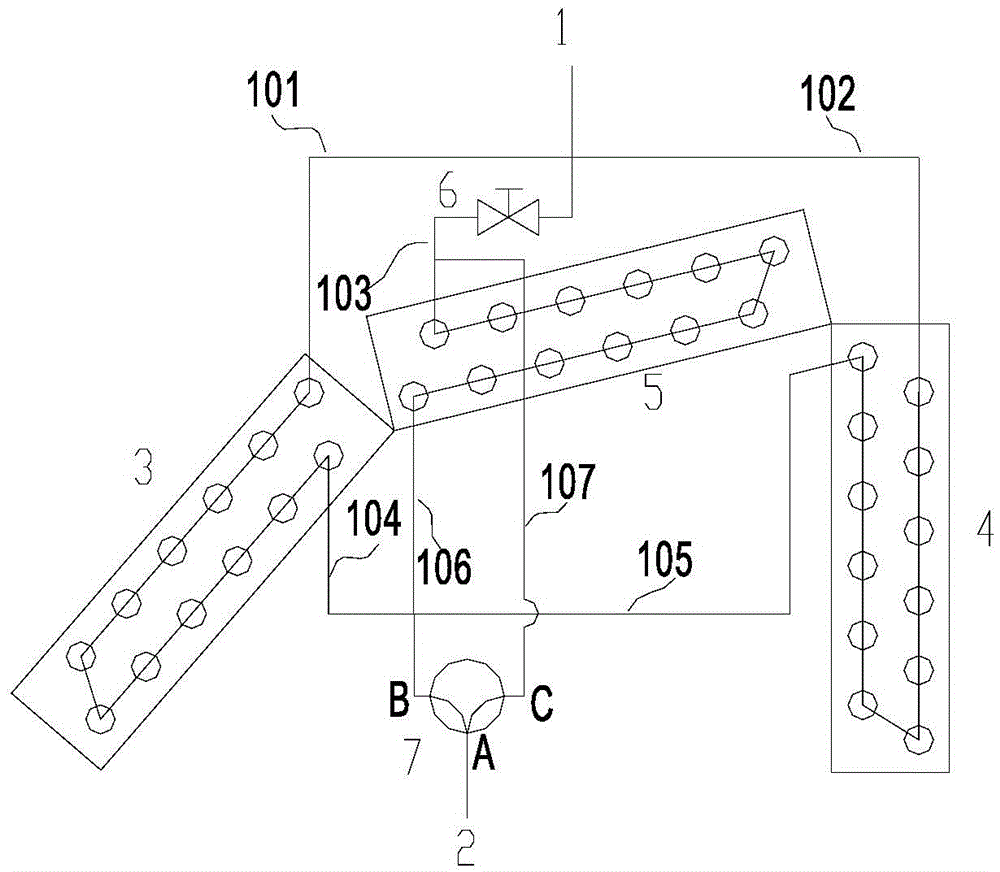

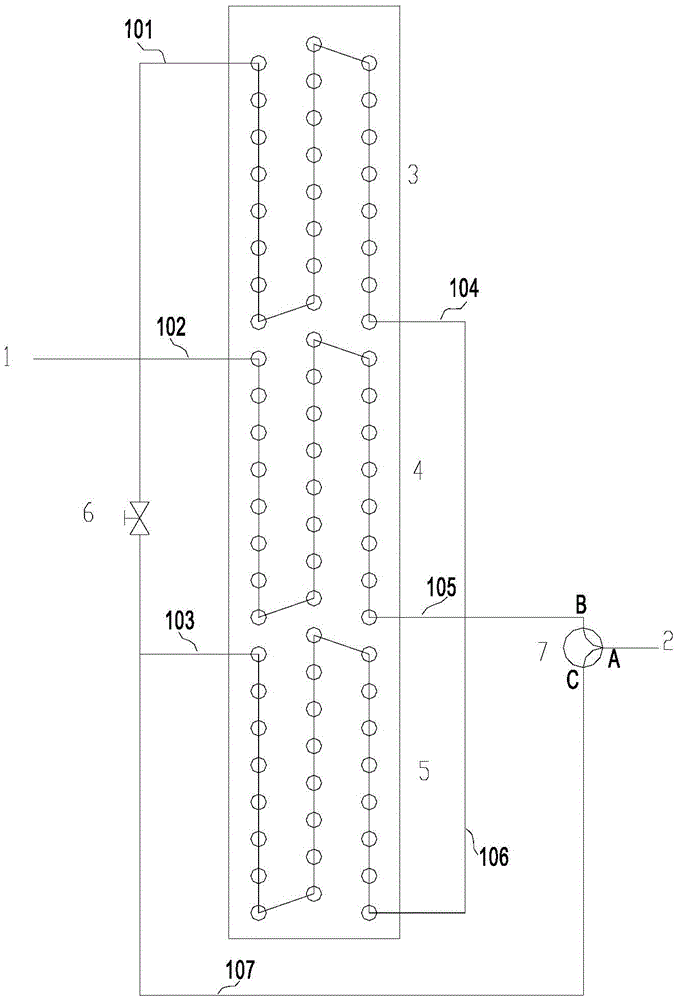

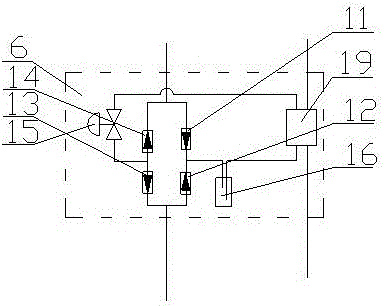

Flow-way-changeable heat pump air conditioner heat exchanger and control method thereof

ActiveCN105466083ARealize switchingImprove heat transfer coefficientMechanical apparatusEvaporators/condensersEngineeringControl valves

The invention provides a flow-way-changeable heat pump air conditioner heat exchanger. The heat exchanger comprises an air collecting opening (1), a liquid collecting opening (2) and three heat exchanging flow ways arranged between the air collecting opening (1) and the liquid collecting opening (2). The three heat exchanging flow ways are connected with one another in parallel. The heat exchanger further comprises a control valve system which controls at least one flow way of the three heat exchanging flow ways to be connected or disconnected so as to achieve switching among the different flow ways. According to the flow-way-changeable heat pump air conditioner heat exchanger, switching of the heat exchanger flow ways in different operation conditions of a unit can be effectively achieved, so that the heat exchanging coefficient is increased and consequentially the heat exchanging effect is improved. The invention further relates to a control method of the air conditioner heat exchanger.

Owner:GREE ELECTRIC APPLIANCES INC

Air conditioning refrigerating device

InactiveCN103743143AIncreased power consumptionReduce efficiencyCompression machines with non-reversible cycleFluid circulation arrangementRefrigerantEvaporator

An air conditioning refrigerating device comprises a high back pressure rotary compressor; an outlet of the high back pressure rotary compressor is connected with an inlet of a condenser; an outlet of the condenser is connected with a liquid inlet of a heat regenerator; the liquid outlet of the heat regenerator is connected with an inlet of a swelling valve; an outlet of the swelling valve is connected with an inlet of an evaporator; an outlet of the evaporator is connected with an air inlet of the heat regenerator; an air outlet of the heat regenerator is connected with an inlet of the high back pressure rotary compressor. According to the air conditioner refrigerating device, refrigerant firstly enters into the high back pressure rotary compressor, enters into the compressor after being compressed into high temperature high pressure air, then is condensed into intermediate temperature high temperature liquid and discharges heat to the air; the refrigerant then flows through the heat regenerator to enter into the swelling valve to be throttled to be in a low temperature low pressure air-liquid mixed state; then the refrigerant enters into the evaporator to change heat with the air in the environment to enable the air temperature to be reduced; accordingly the refrigerating effect is achieved. The air conditioner refrigerating device has the advantages of improving the compressor efficiency and a refrigeration coefficient of a refrigeration system and being good in lubricating oil return.

Owner:XI AN JIAOTONG UNIV

Method for preparing liquid by low-temperature rectification

InactiveCN108286870AIncrease unit cooling capacityReduce work stressSolidificationLiquefactionEngineeringThermal expansion

The invention relates to a method for preparing liquid by low-temperature rectification. The method comprises the steps that 1, raw material air passes through an air compressor, an air pre-cooling system and an air purification system; 2, the purified air enters the heat exchanger continuously, and air in the heat exchanger is divided into two strands, the first strand of air passes through the heat exchanger to be condensed into liquid to enter a rectifying lower tower, the second strand of air is pumped out and then enters a low-temperature expansion machine for expansion, part of the air enters the rectifying lower tower, and the other part of the air is returned to the air compressor inlet or the air pre-cooling system after being subjected to repeated thermal expansion by the heat exchanger; 3, liquefied air after throttling which flows into the lower tower and the expanded part of air into the rectifying lower tower for rectification, so as to obtain a liquid nitrogen product;and rectifying is carried out again through a rectifying upper tower to obtain the liquid oxygen product. According to the method, the exhaust pressure of the circulating air compressor is effectivelyreduced, the unit refrigerating capacity of the expansion machine is improved, and the purposes of enabling the equipment to be easy to operate and reducing the primary investment of the equipment are achieved.

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

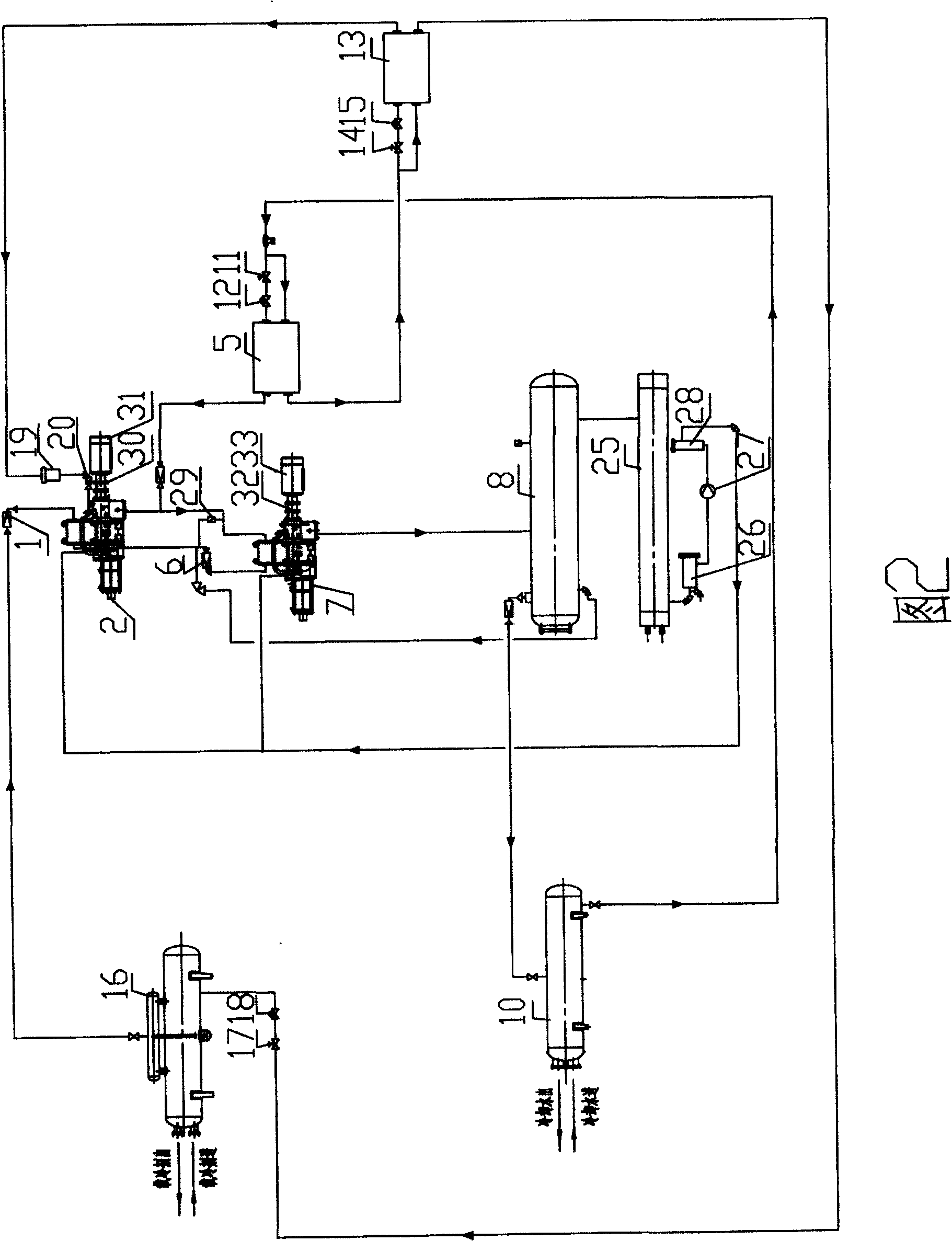

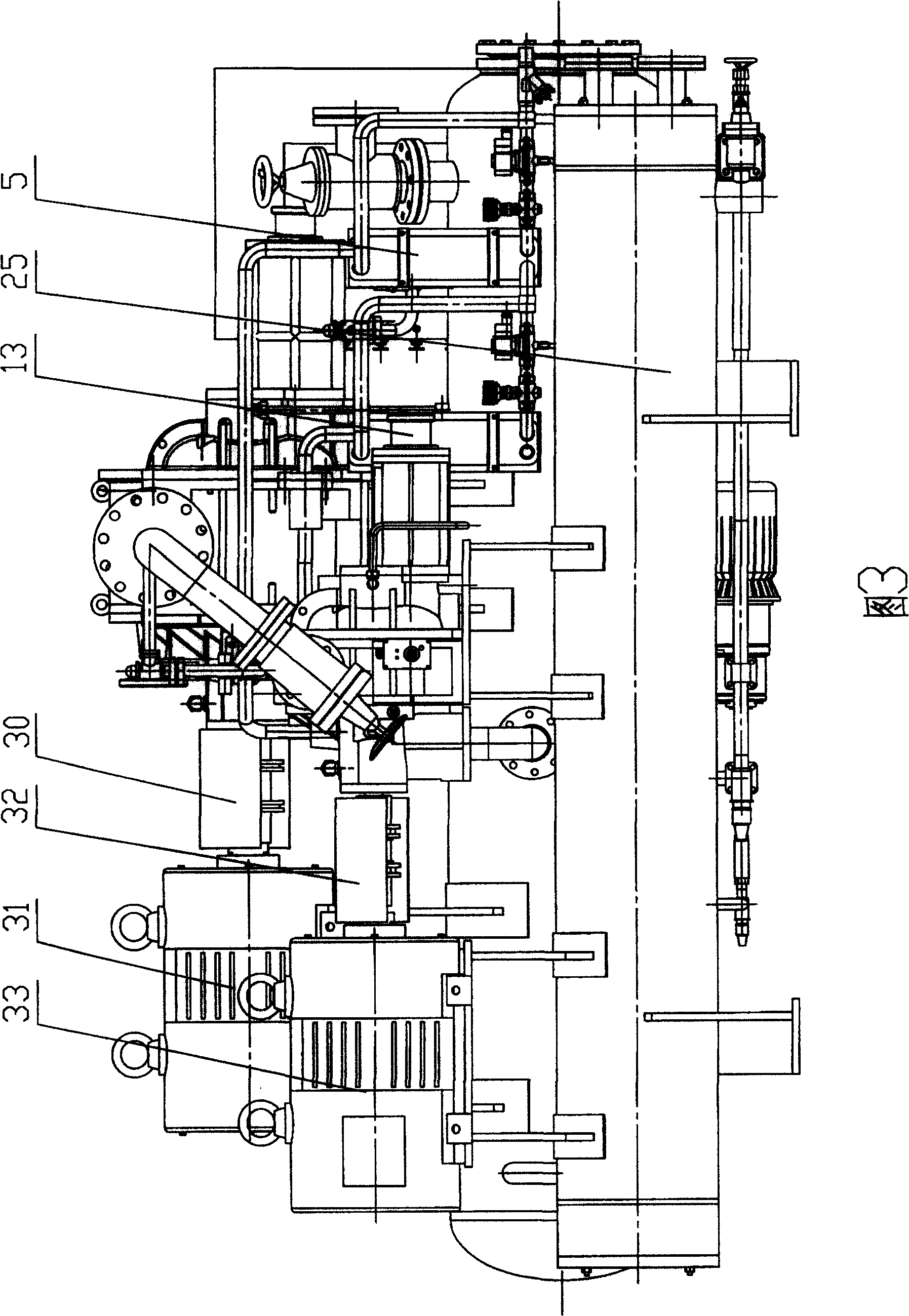

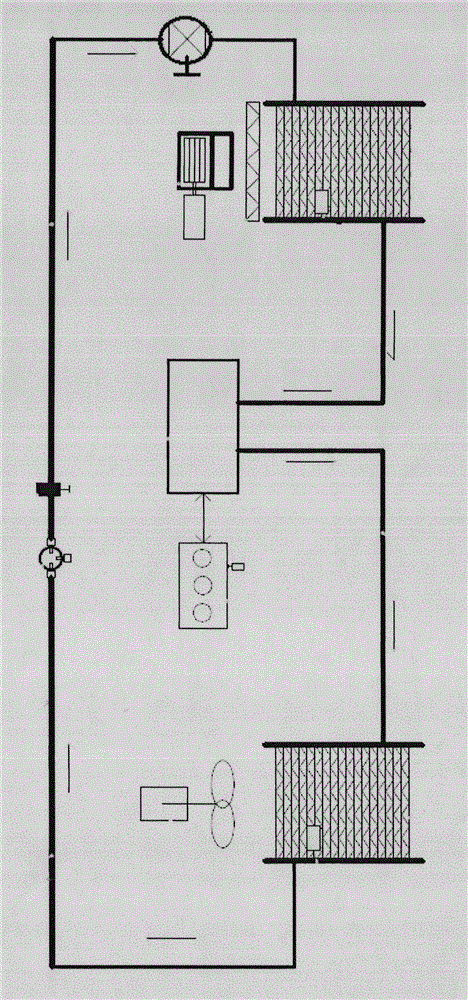

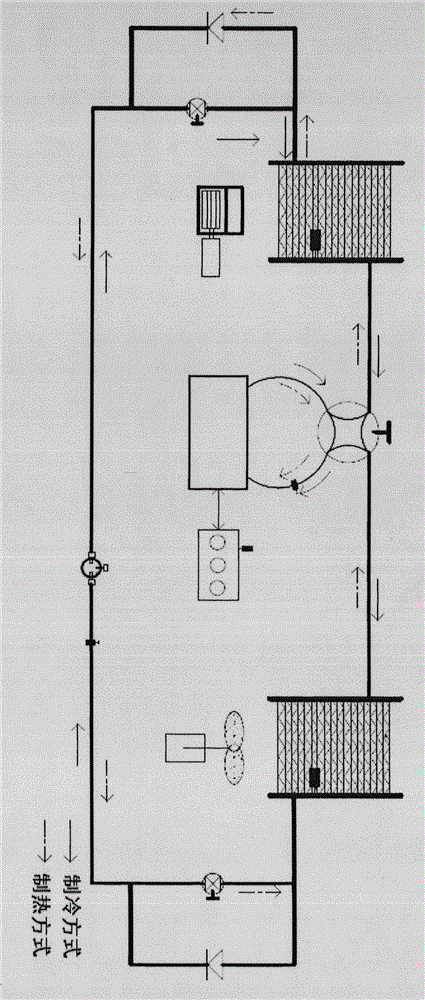

Dual-locomotive and dual-stage screw refrigerating compressor set

ActiveCN100447501CLow powerRun energy savingCompression machines with non-reversible cycleCompression machines with cascade operationRefrigeration compressorDual stage

This kind of double-machine, double-screw cold compressor system mainly consists of evaporator, compressor in low-pressure zone, compressor in high-pressure zone, recycle unit to separate oil, condenser, condenser in the middle part, low-pressure economizer system. There is no inspiration passage between evaporator and compressor in high-pressure zone. The vent on compressor in low-pressure zone connects directly with the air entry on compressor in high-pressure. Compressors low-pressure zone and high-pressure zone share one recycle unit of oil separation. Condenser, condenser in the high-pressure zone, economizer system in low-pressure zone and evaporator are linked up in that order so that part of the refrigerating medium can absorb enough heat to boil and evaporate, provide vapor at a temperature near saturation to the compressor in the high-pressure zone and supply vapor to the compressor in the low-pressure zone. Meanwhile, the other part of refrigerating medium will be passed to the evaporator after being cooled twice for recycle. It is the best choice among the products of refrigeration and deepfreeze in low temperature because of its tidy and compact structure, reasonable layout, small size, stable and credible operation, low cost and high cooling performance.

Owner:武汉新世界制冷工业有限公司

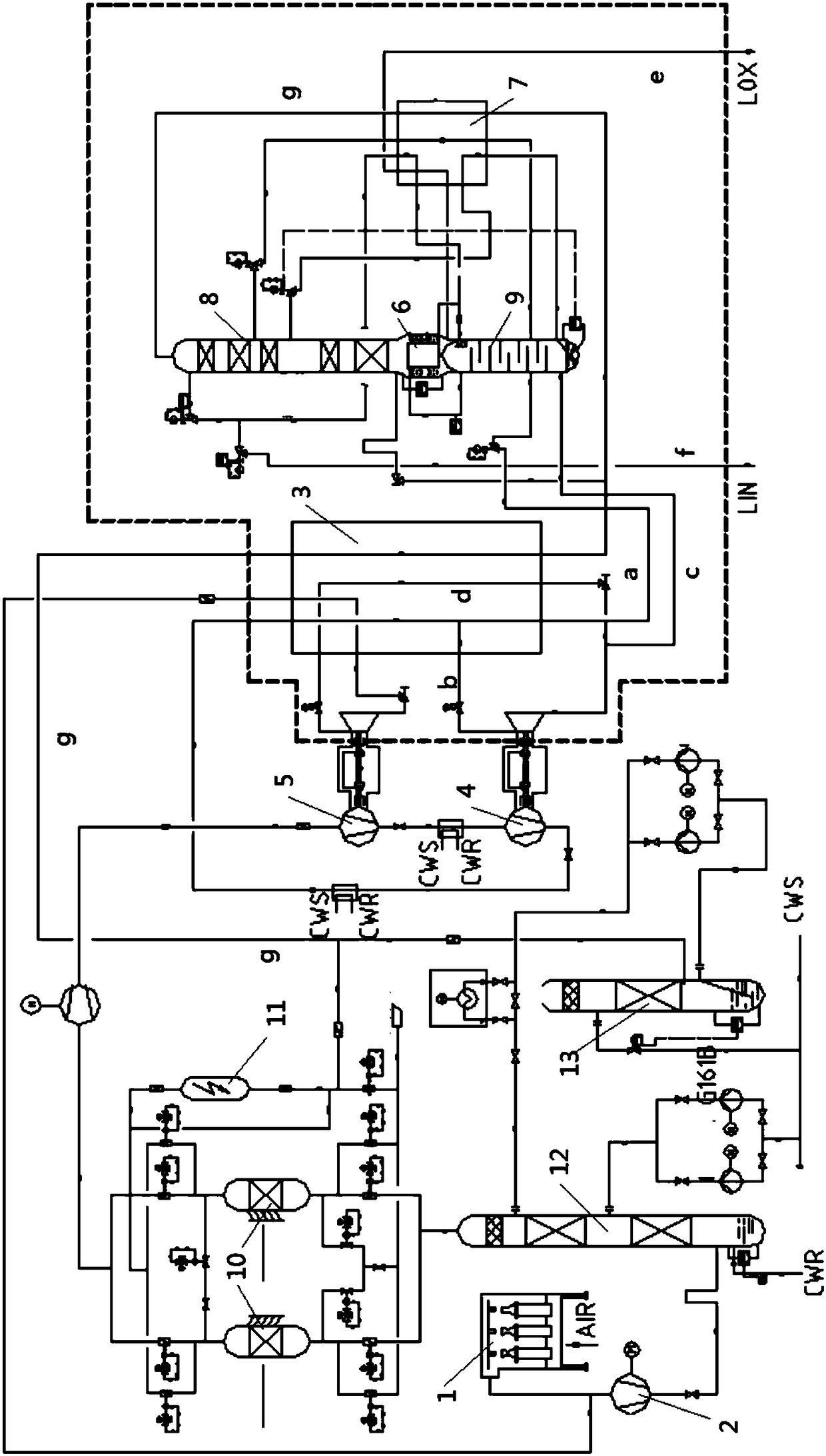

Air separation technique

ActiveCN105466154AIncrease unit cooling capacityReduce processing energy consumptionSolidificationLiquefactionCooling towerEngineering

The invention belongs to the field of air separation and discloses an air separation technique. The problem of low purity of oxygen produced through an existing air separation technique is solved. The technique includes the steps that (1) air is filtered and enters an air compressor to be compressed, and the compressed air is cooled and washed in a cooling tower; (2) part of purified air is cooled to a dew point and then enters the bottom of a lower tower, the other part of purified air flows into a booster compressor to be pressurized, the pressurized air is divided into two ways, one way of air is subjected to expansion cooling and delivered into an upper tower, and the other way of air passes through a heat exchanger and flows into the lower tower; (3) the air is subjected to preliminary rectification in the lower tower, liquid air passes through a supercooler and then enters the upper tower, part of liquid oxygen is delivered into a storage system, and the other part of liquid oxygen is reheated and then enters an oxygen pipe network; and (4) argon distillate is extracted from the middle of the upper tower and delivered into a crude argon column, and pure nitrogen extracted from the top of the upper tower of a rectifying tower passes through the supercooler, then enters the heat exchanger and is delivered into a water-cooling tower and a user pipe network. By means of the air separation technique, the purity of produced oxygen reaches 99.8%.

Owner:宝泰隆新材料股份有限公司北京技术研发中心

Air conditioning refrigeration system

InactiveCN103968618AReduced steam absorption heating lossLow efficiencyCompressorMechanical apparatusEngineeringHigh pressure

Provided is an air conditioning refrigeration system. An outlet of a high-back-pressure rotary compressor is connected with an inlet of a condenser, an outlet of the condenser is connected with a liquid inlet of a heat regenerator, a liquid outlet of the heat regenerator is connected with an inlet of an expansion valve, an outlet of the expansion valve is connected with an inlet of an evaporator, an outlet of the evaporator is connected with a gas inlet of the heat regenerator, and a gas outlet of the heat regenerator is connected with an inlet of the high-back-pressure rotary compressor. Refrigerating fluid enters the high-back-pressure rotary compressor firstly, and is compressed into high-temperature high-pressure gas entering the condenser, the gas is condensed into intermediate-temperature high-pressure liquid, and heat is discharged into air. The refrigerating fluid flows through the heat regenerator and enters the expansion valve, and is throttled to be in a low-temperature low-pressure gas-liquid mixing state, then the refrigerating fluid enters the evaporator, heat exchange is carried out on the refrigerating fluid and the air in the environment, the temperature of the air is reduced, and therefore the refrigeration effect is achieved. According to the system, efficiency and stability are improved, oil return is good, the probability of blocking capillary tubes is reduced, and the injection amount of the refrigerating fluid is reduced.

Owner:XI AN JIAOTONG UNIV

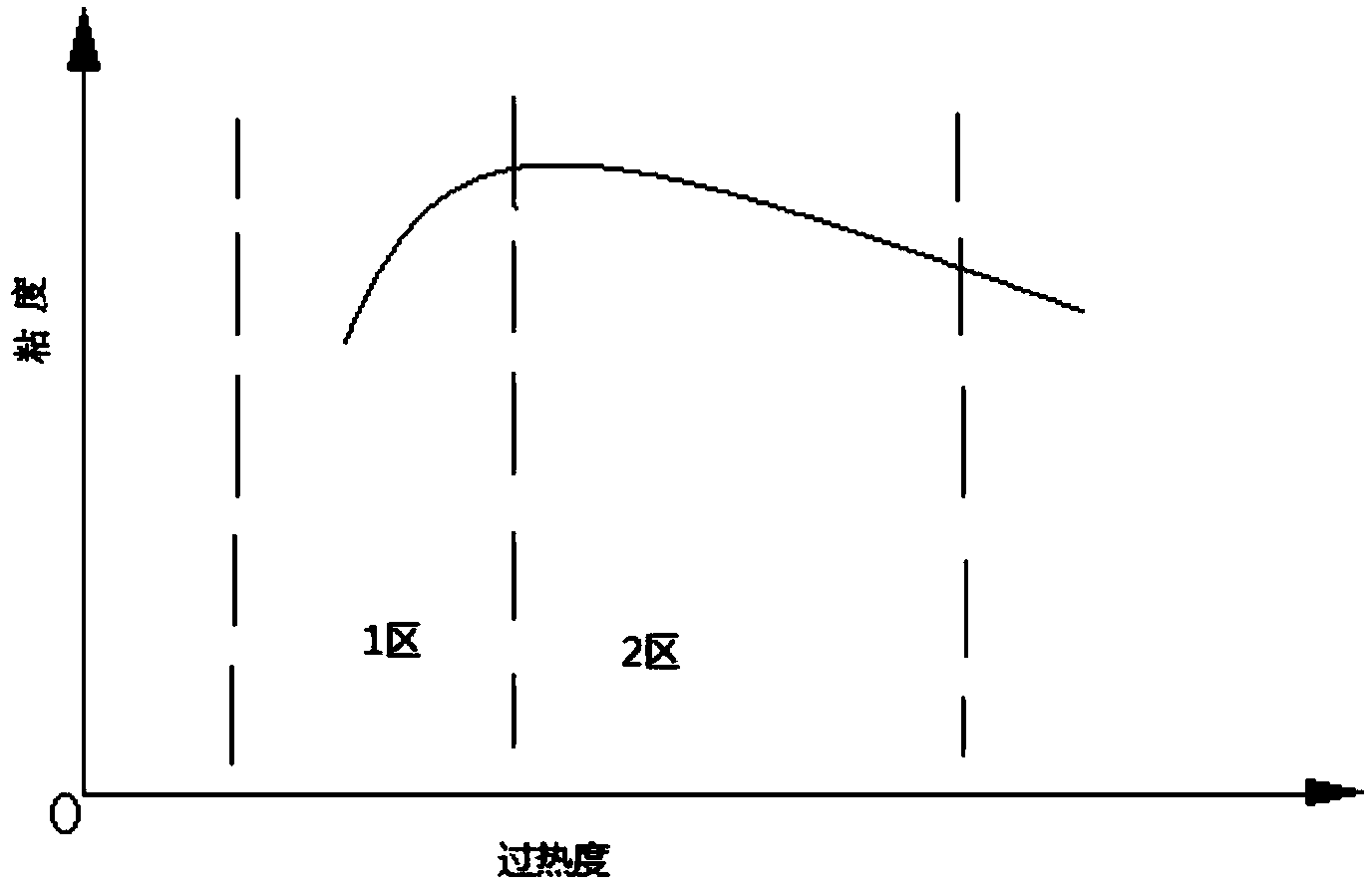

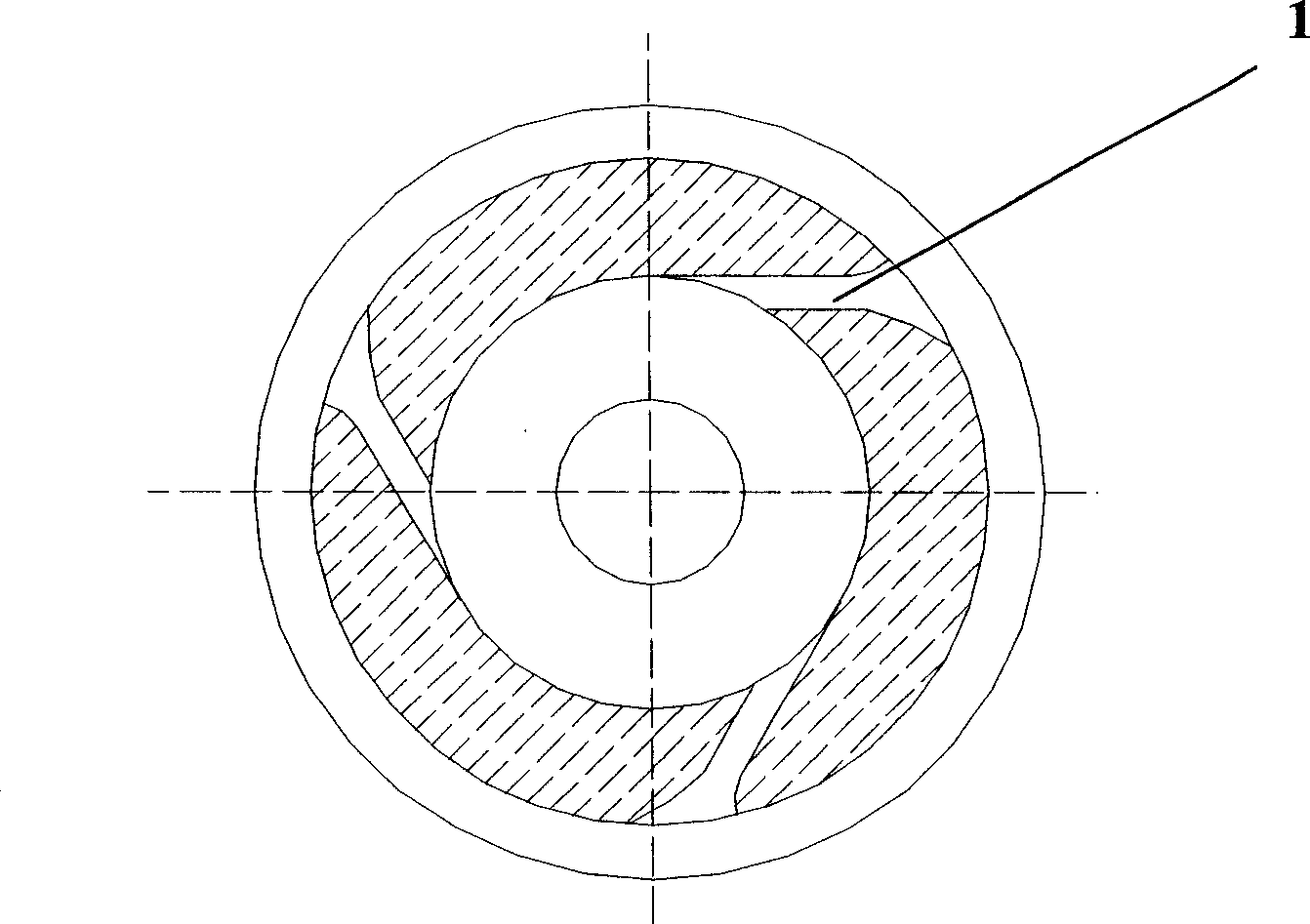

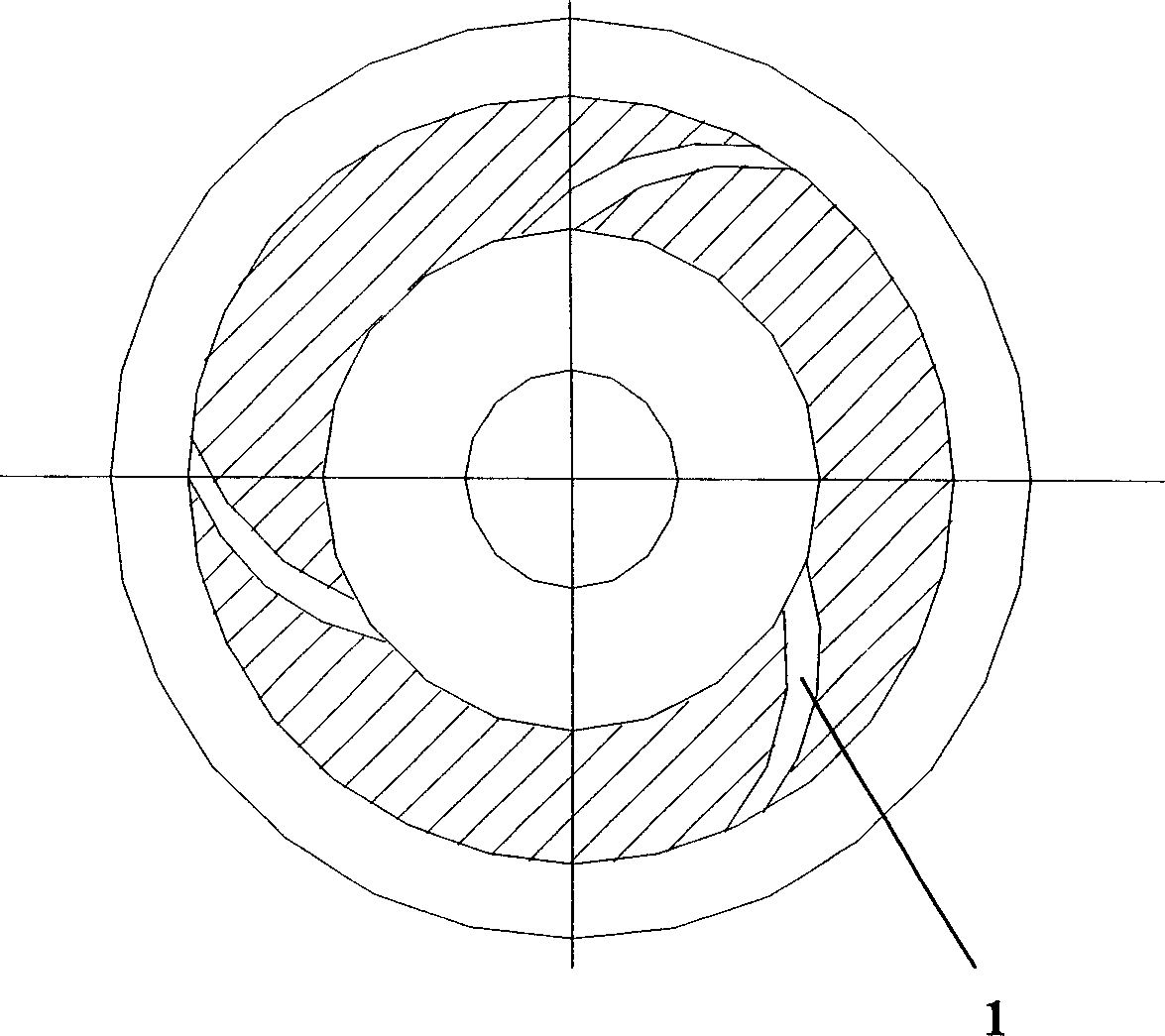

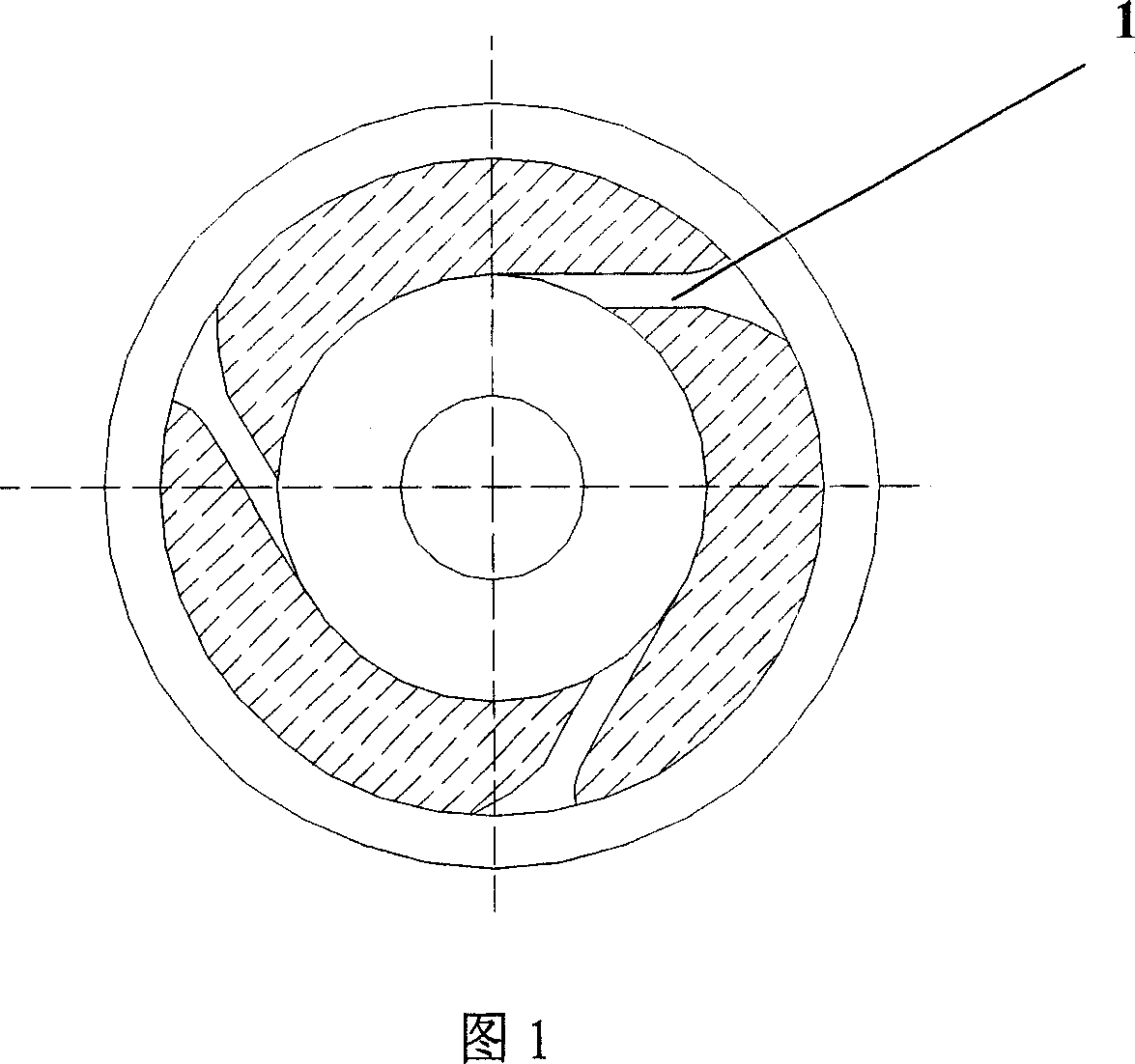

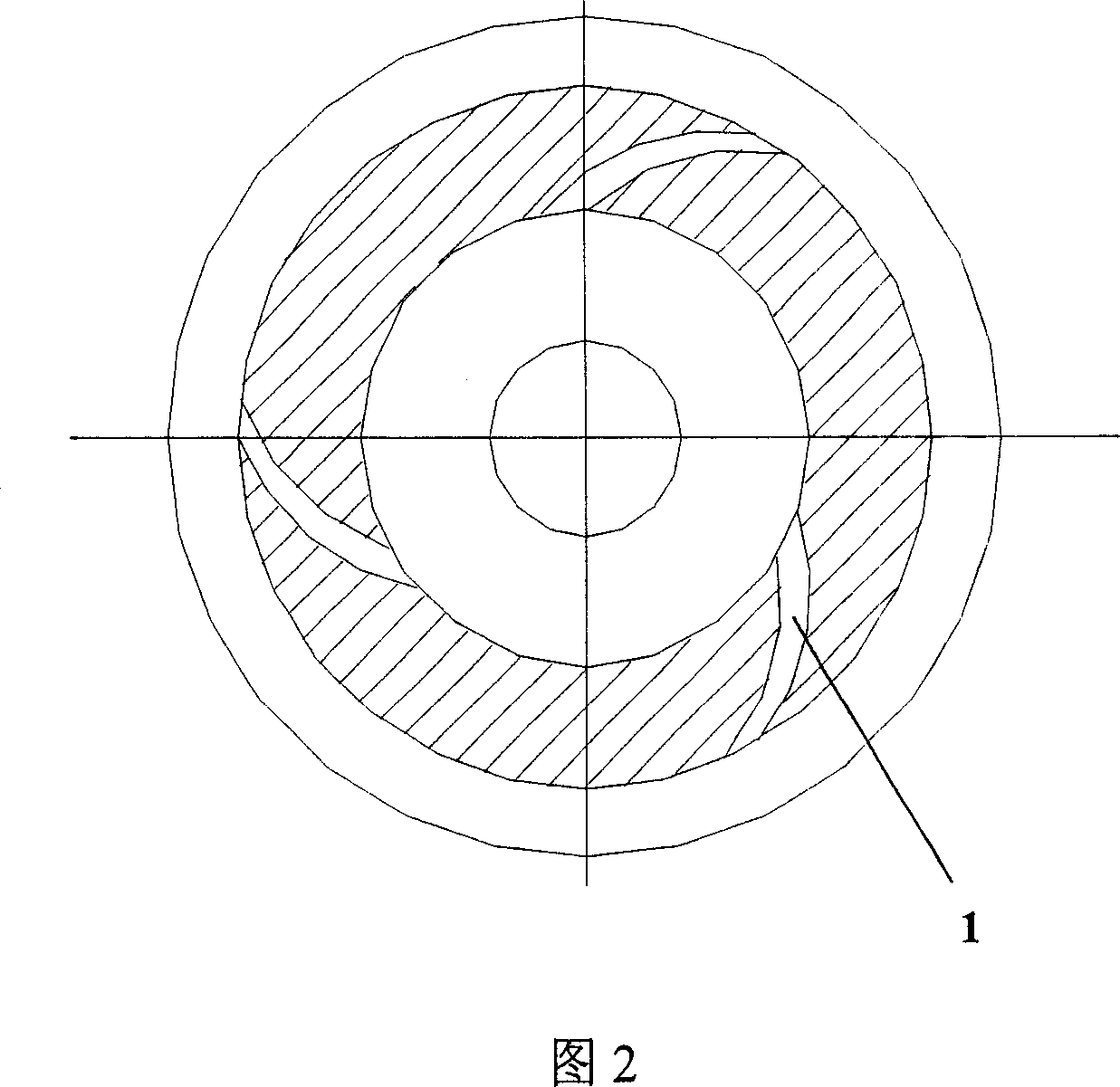

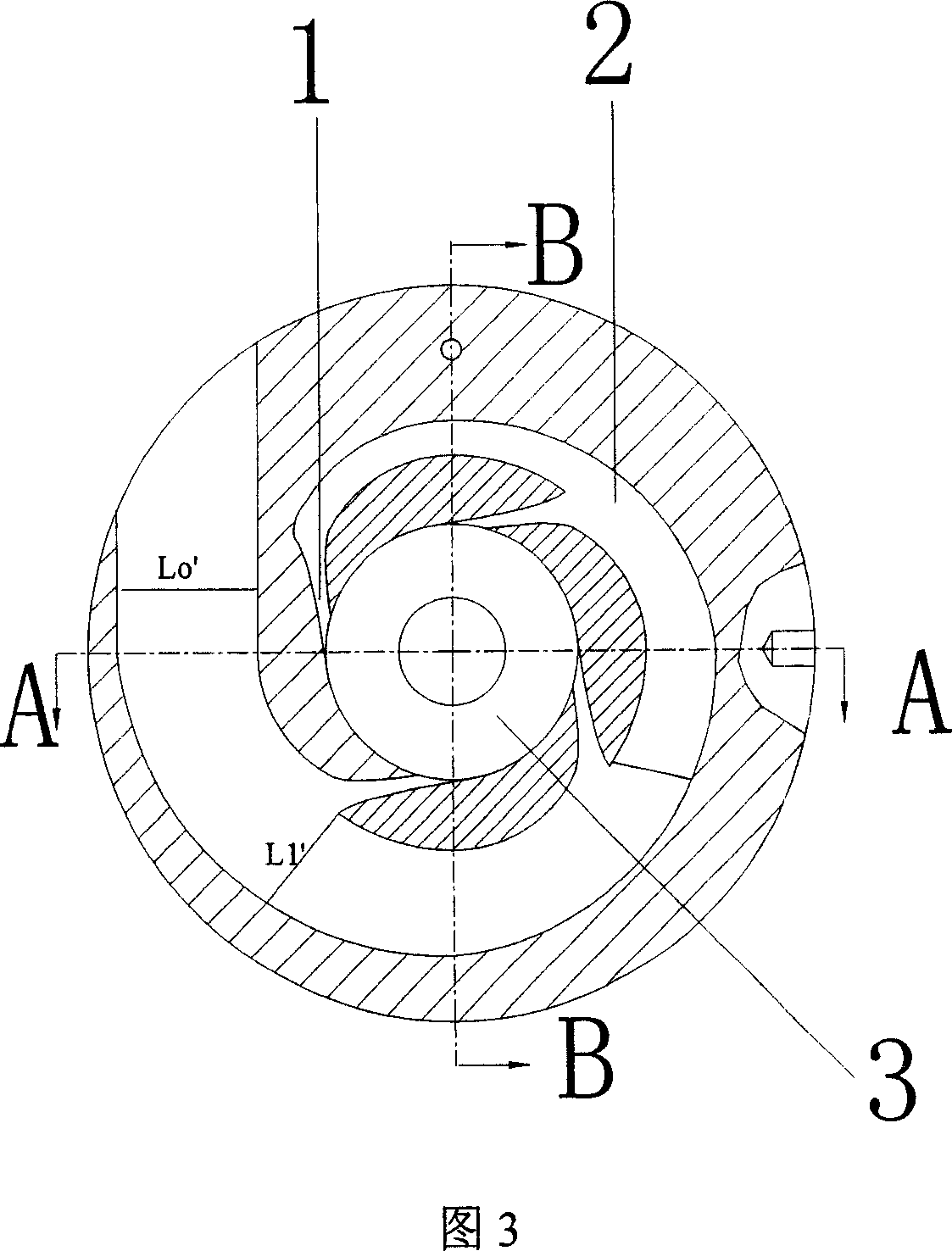

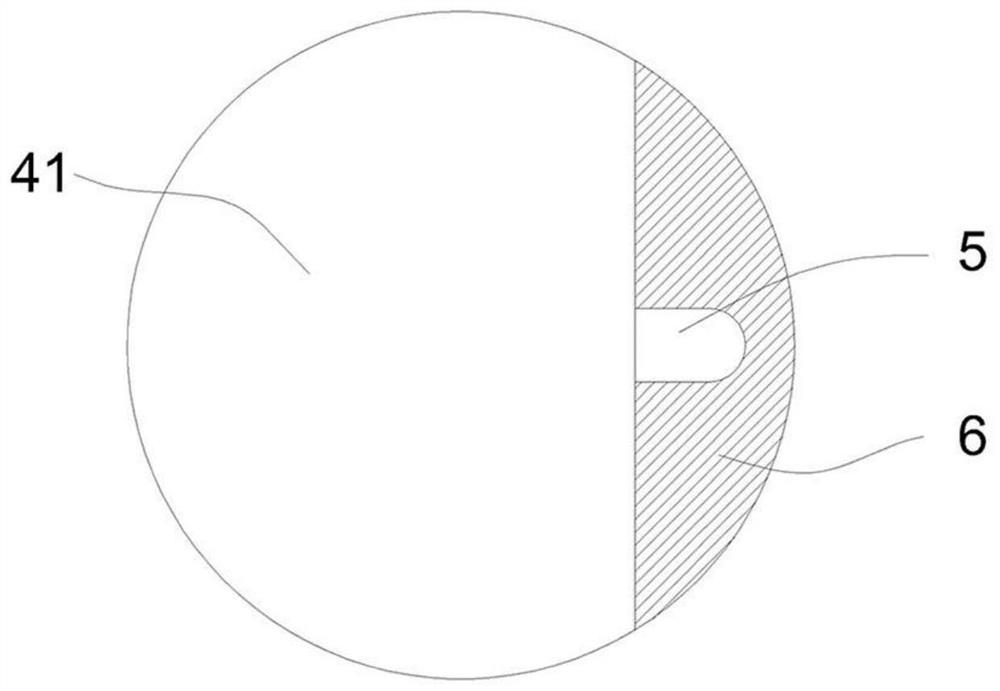

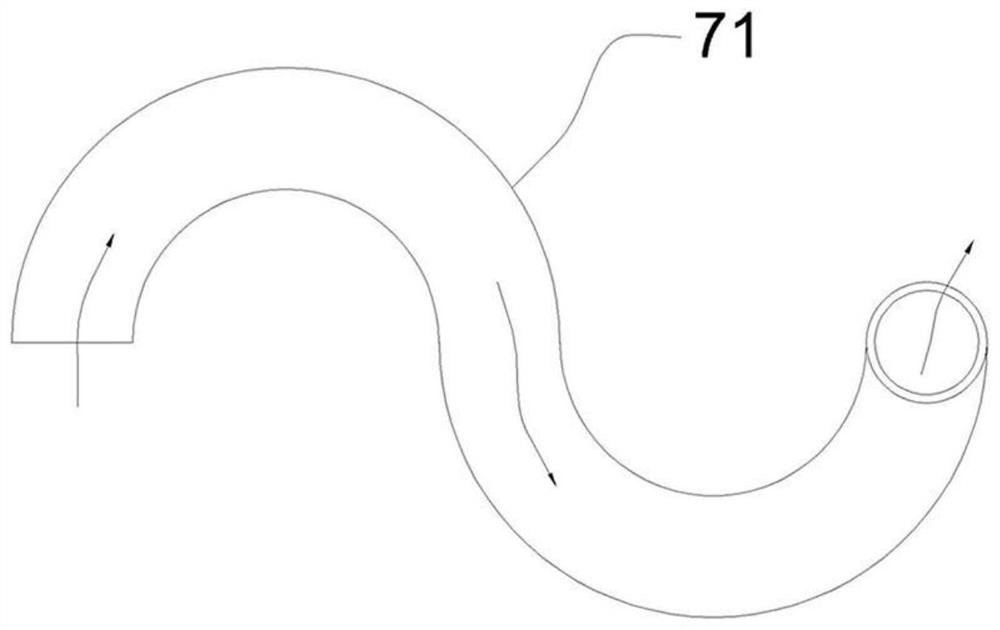

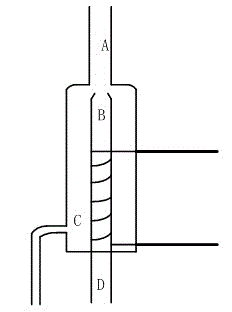

Nozzle of vortex tube

InactiveCN1687673AImprove cooling effectImprove cooling temperature effectCompression machinesRefrigeration temperatureEngineering

The invention is the vortex tube nozzle and belongs to the refrigeration field. The characteristics are: the flow channel (1) of the nozzle adopts the geometrical symmetry, which is that the central axis line of the flow channel is designed by the equal Mach grads and makes the air flow increase along the axis line to reduce the lost of the air flow; the air intake front channel (2) of the nozzle adopts the design of the same plane with the nozzle channel (1) and the equal air speed, which is to ensure the speed of the normal face of the central line of the air channel consistent to the intake of the vortex tube. The invention improves the refrigeration temperature effect of the vortex tube and increases the chill flow ratio of the maximum refrigeration to improve the unit refrigeration volume and the refrigeration coefficient.

Owner:BEIJING UNIV OF TECH

Jet type supercooling refrigeration system

PendingCN109855323AIncrease subcoolingExtended service lifeCompression machinesSubcoolersEngineeringHigh pressure

The invention discloses a jet type supercooling refrigeration system, and aims at providing a refrigeration system capable of obtaining a large degree of supercooling and low operation cost. The jet type supercooling refrigeration system comprises a main refrigeration cycle and a jet subcooling refrigeration cycle; the cooling heat of the high temperature gas of the compressor exhaust port in themain refrigeration cycle drives an injector in the jet subcooling refrigeration cycle. The refrigeration system can obtain a large degree of subcooling, and the high-pressure refrigerant liquid in a generator is heated by the cooling heat of the high-temperature gas of the compressor exhaust port, so that the jet supercooling cycle can use the waste heat effectively; without other energy input, the operation cost is reduced. Meanwhile, the refrigerant entering a main condenser has a lower temperature, the space occupied by the condenser is reduced, the cooling process is more sufficient, the energy efficiency of the system is improved effectively; and the service life of the compressor is prolonged.

Owner:TIANJIN UNIV OF COMMERCE

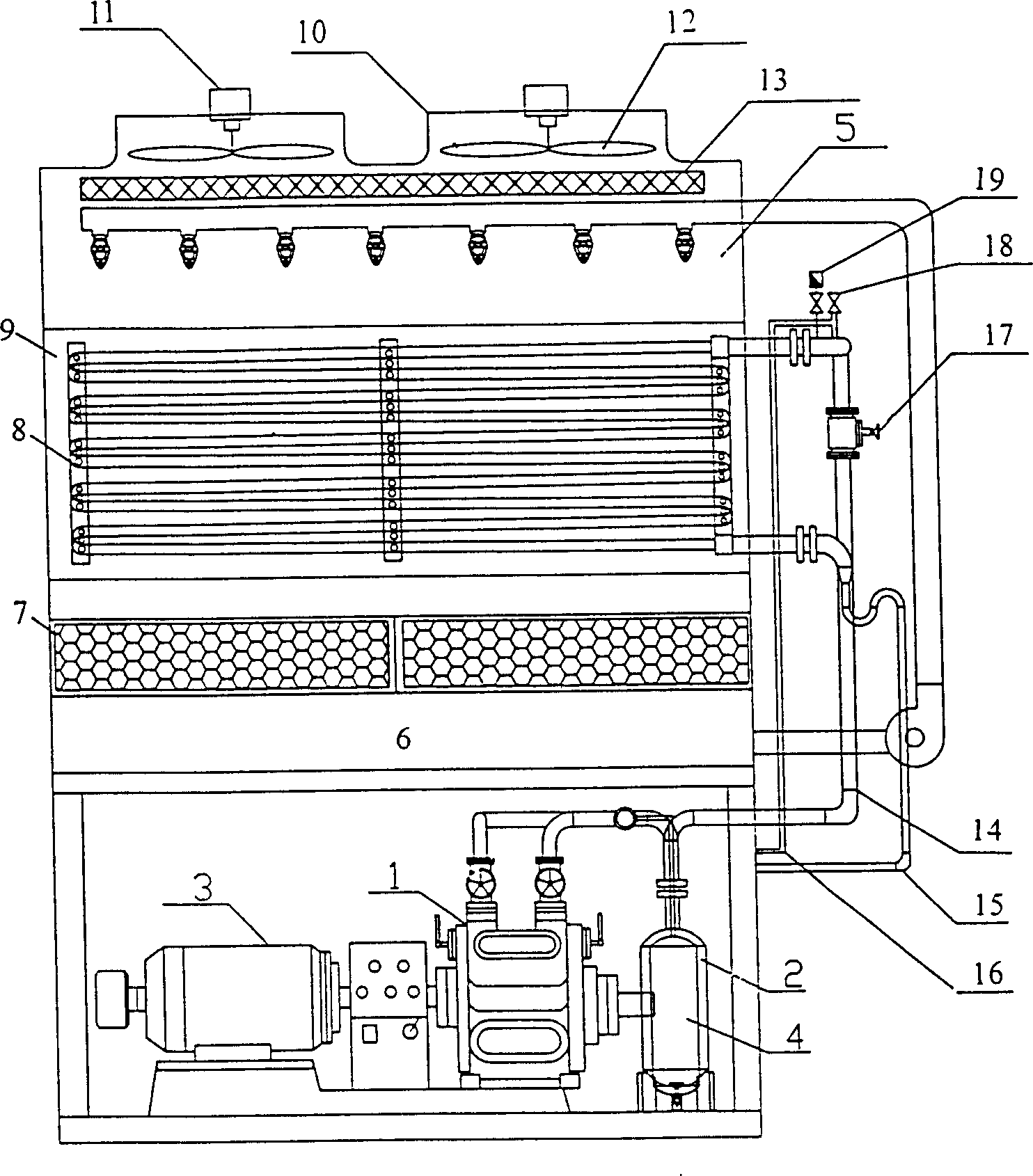

Condenser set of evaporated compressor

InactiveCN1746592ANo consumptionReduce headCompression machines with non-reversible cycleEvaporators/condensersCooling towerCirculator pump

An evaporative compressor condensing machine set comprises a condenser, a compressor, a liquid-storage container, an oil catcher and an oil separator. The condenser is an evaporative condenser, in which the spray pipe is connected with one end of the spray pump. The other end of the spray pump is in communication with the pool. On the spray pipe, several nozzles are mounted, and under which a coiler group consists of the elliptic pipes. There is a window and the spray pool under the evaporation coil group.

Owner:金兴才

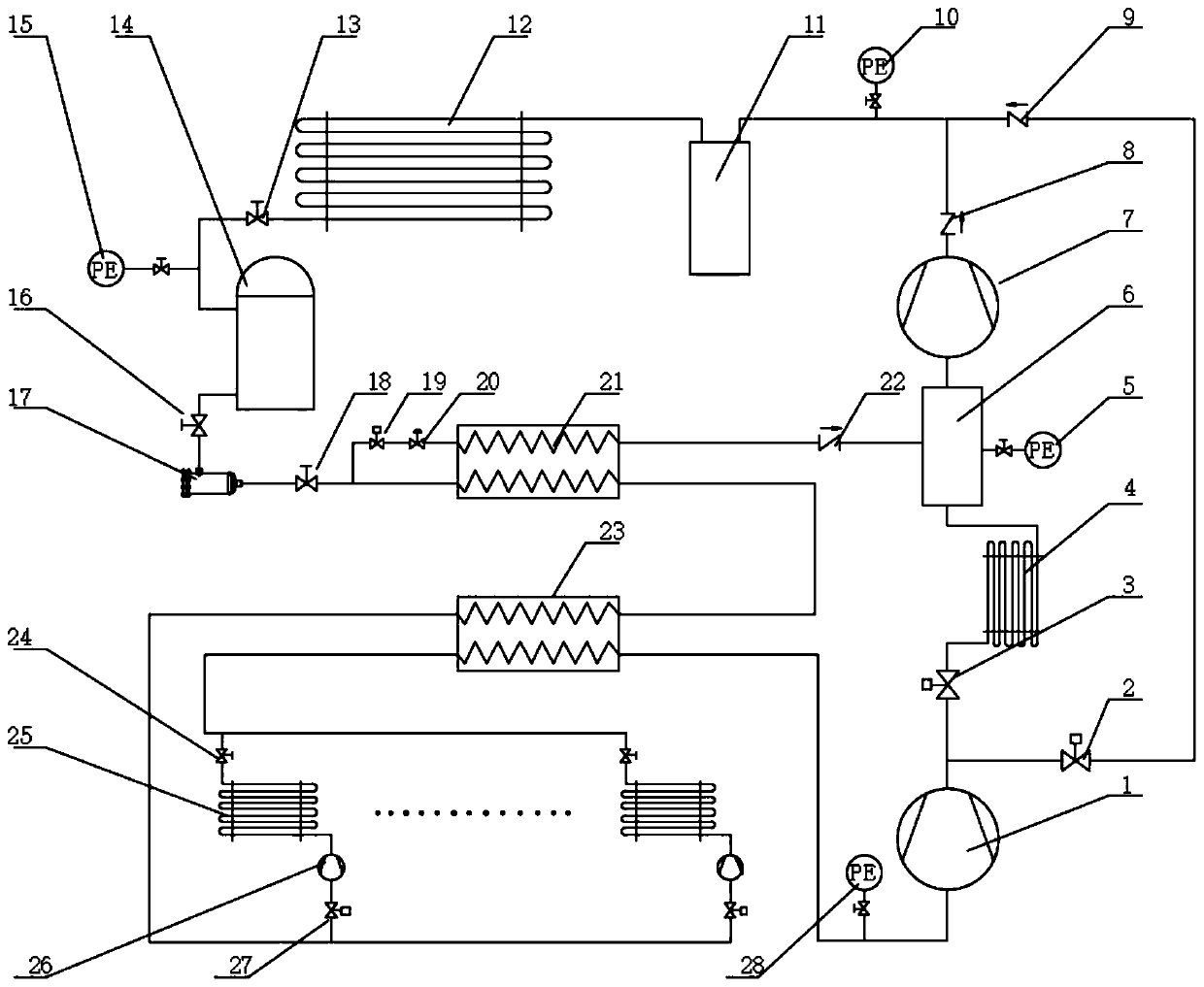

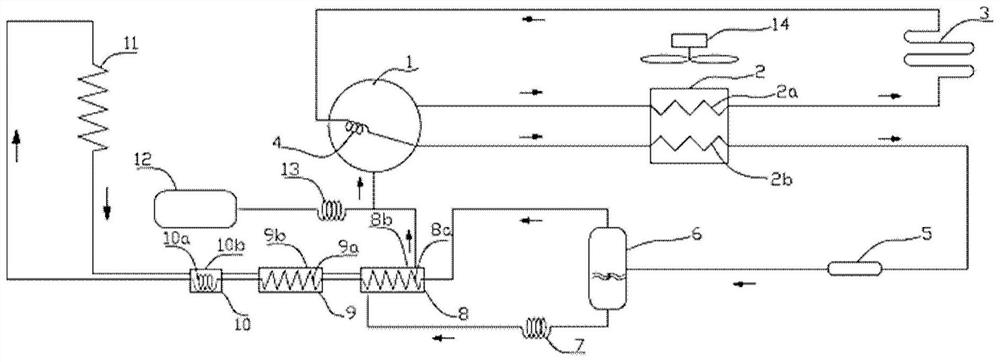

Energy saving type CO2 double-machine double-level refrigeration multi-split air conditioner system

PendingCN111102759AIncrease CO2 unit cooling capacityImprove the energy efficiency ratio of the whole machineMechanical apparatusCompression machinesIntercoolerOil separation

The invention relates to an energy saving type CO2 double-machine double-level refrigeration multi-split air conditioner system. A subcritical compressor, a mixing barrel, a transcritical compressor,a gas storage tank, an intermediate cooler and a heat regenerator are included. The subcritical compressor is connected with the bottom of the mixing barrel through a first gas cooler. The top of themixing barrel is connected with the transcritical compressor. The transcritical compressor is connected with a second gas cooler through an oil separator. The second gas cooler is connected with the gas storage tank. The gas storage tank is connected with two gas inlet pipes of the intermediate cooler through a drying filter. The intermediate cooler is connected with a plurality of air coolers through the heat regenerator. After being connected in parallel, air outlet pipes of the air coolers are connected with the heat regenerator, and the heat regenerator is connected with a gas inlet pipe of the subcritical compressor. The multi-split air conditioner system is combined with the CO2 double-machine double-level refrigeration technology to be applied to the medium-low-temperature field, the double-mode refrigeration principle energy saving design characteristic is adopted, and for the industry field of medium-low temperature environment bins and medium-low temperature refrigeration houses and cold chains, future market application prospects are very wide.

Owner:南京久鼎精机冷冻设备有限公司

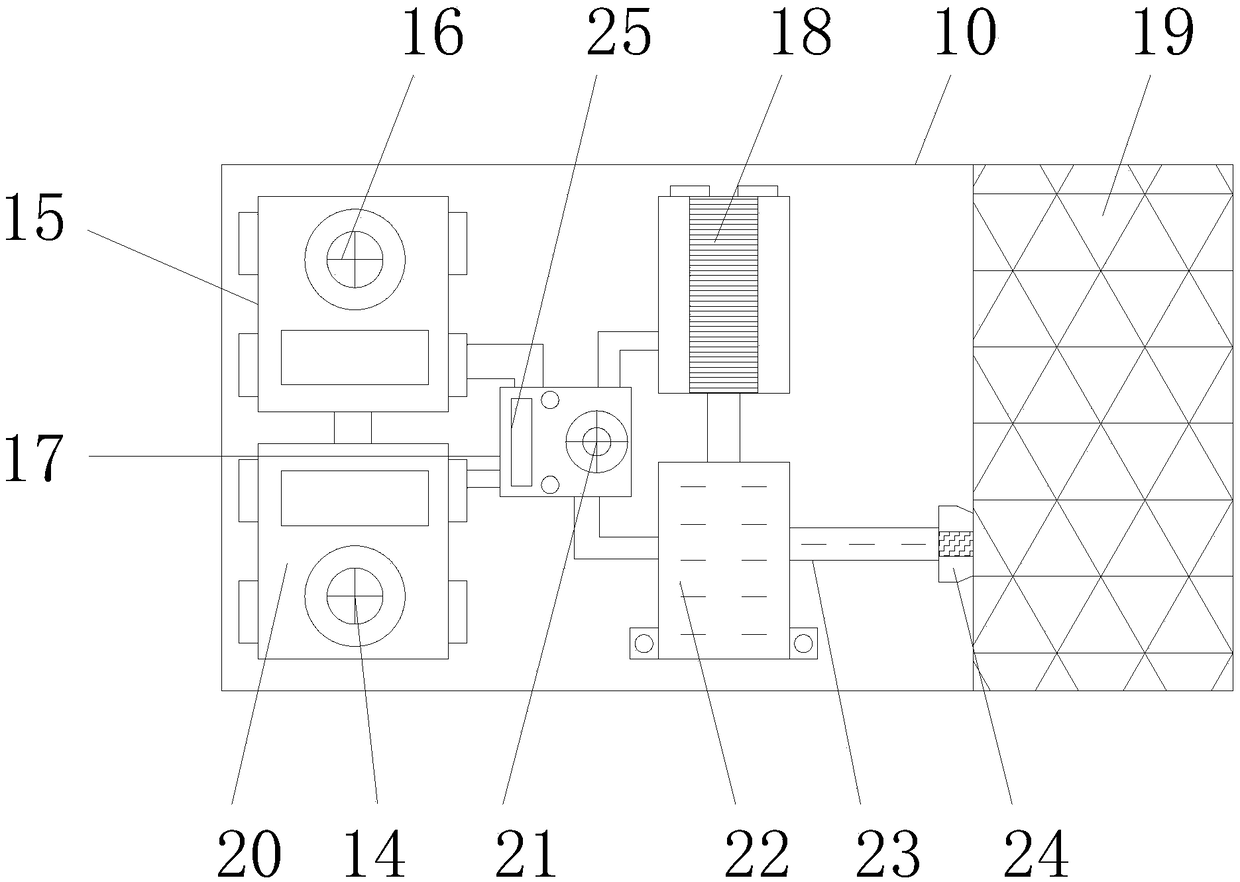

Carbon dioxide refrigeration equipment

InactiveCN108775723AReduce the temperatureReduce invalid gas contentCompression machinesGas compressorLiquid storage tank

The invention discloses carbon dioxide refrigeration equipment comprising a base. The right side of the base is provided with an electric control box, and the one inner side of the base is provided with a condenser; the upper and lower parts of the other inner side of the base are fixedly connected to a first screw compressor and a second screw compressor separately, and the upper and lower partsof the interior center of the base are fixedly connected to a heat exchanger and a liquid storage tank separately; the middle section between the first screw compressor and the heat exchanger is fixedly connected an expansion machine, and the upper end of the base is provided with a box body; and the left and right sides of the inner top end of the box body are provided with a low temperature evaporator and a medium temperature evaporator separately. According to the carbon dioxide refrigeration equipment, through arrangement of the first screw compressor, the second screw compressor, a firstregenerator, a second regenerator, an economizer, the low temperature evaporator, the medium temperature evaporator, the gas heat exchanger, the expansion machine and a heat pump unit structure, the carbon dioxide refrigeration equipment has the advantages of energy saving, environmental protection, good refrigeration effect, continuous refrigeration and multiple functions.

Owner:芜湖盘云石磨新能源科技有限公司

A kind of air separation process method

ActiveCN105466154BIncrease unit cooling capacityReduce processing energy consumptionSolidificationLiquefactionCooling towerGas compressor

The invention belongs to the field of air separation and discloses an air separation technique. The problem of low purity of oxygen produced through an existing air separation technique is solved. The technique includes the steps that (1) air is filtered and enters an air compressor to be compressed, and the compressed air is cooled and washed in a cooling tower; (2) part of purified air is cooled to a dew point and then enters the bottom of a lower tower, the other part of purified air flows into a booster compressor to be pressurized, the pressurized air is divided into two ways, one way of air is subjected to expansion cooling and delivered into an upper tower, and the other way of air passes through a heat exchanger and flows into the lower tower; (3) the air is subjected to preliminary rectification in the lower tower, liquid air passes through a supercooler and then enters the upper tower, part of liquid oxygen is delivered into a storage system, and the other part of liquid oxygen is reheated and then enters an oxygen pipe network; and (4) argon distillate is extracted from the middle of the upper tower and delivered into a crude argon column, and pure nitrogen extracted from the top of the upper tower of a rectifying tower passes through the supercooler, then enters the heat exchanger and is delivered into a water-cooling tower and a user pipe network. By means of the air separation technique, the purity of produced oxygen reaches 99.8%.

Owner:宝泰隆新材料股份有限公司北京技术研发中心

Nozzle of vortex tube

InactiveCN1304798CImprove cooling effectImprove cooling temperature effectCompression machinesRefrigeration temperatureEngineering

Owner:BEIJING UNIV OF TECH

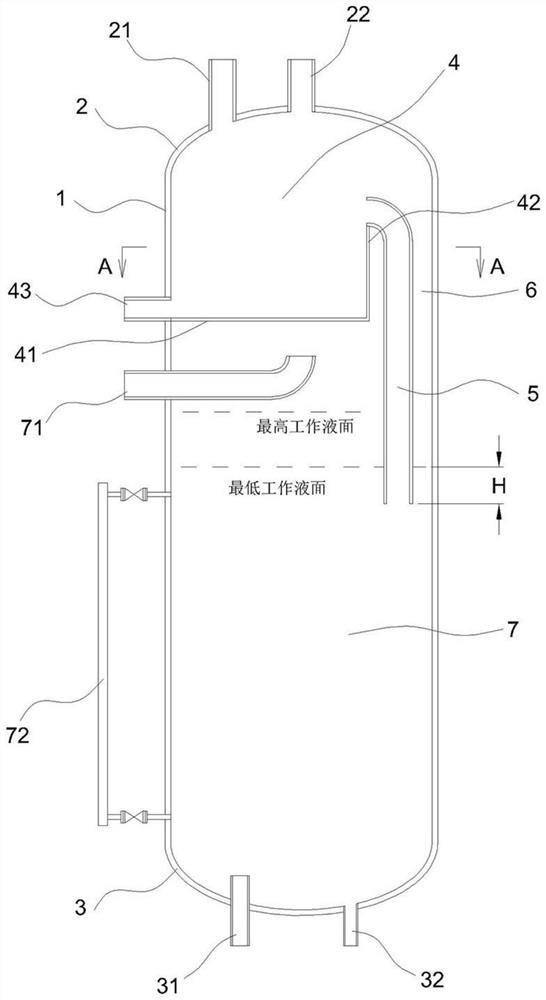

Vertical liquid reservoir and refrigerating system with liquid reservoir

The invention discloses a vertical liquid reservoir. The vertical liquid reservoir comprises a cavity formed by a barrel, an upper sealing body and a lower sealing body, a separation device for separating the cavity into a buffer chamber and a liquid storage chamber, a downcomer, a gas flow channel and a liquid level control device; the downcomer and the gas flow channel are used for communicating the buffer chamber with the liquid storage chamber; the lower end of the downcomer stretches into the position below the lowest working liquid level of the liquid storage chamber; the upper sealing body is provided with a liquid inlet pipe entering the buffer chamber and a first gas outlet pipe keeping a proper distance from the liquid inlet pipe; a first liquid outlet pipe is arranged at the bottom of the buffer chamber; the lower sealing body is provided with a discharge port and a second liquid outlet pipe stretching into the liquid storage chamber; the liquid storage chamber is provided with a first gas inlet pipe located above the highest working liquid level; and the liquid level control device is used for controlling the liquid level height of the liquid storage chamber. According to the vertical liquid reservoir, the downcomer and the gas flow channel are arranged between the buffer chamber and the liquid storage chamber which are divided up and down, so that even if the pressure of the liquid storage chamber is high, the pressure in the liquid reservoir can be balanced, and it is ensured that liquid in the buffer chamber can smoothly flow into the liquid storage chamber through the downcomer.

Owner:TAIZHOU LONGJIANG CHEM MACHINERY TECH

Heat pump drying system with deep supercooling

InactiveCN108332553AIncrease subcoolingImprove cooling effectHeat pumpsRefrigeration safety arrangementEvaporatorEngineering

The invention relates to a heat pump drying system with deep supercooling capable of being used in the drying field of various materials. The system comprises a plurality of independent heat pump units, a subcooler unit, a fan and a central controller, wherein each of the heat pump units comprises a compressor, a condenser, a liquid storage device, a drying filter, an expansion valve and an evaporator. The heat pump unit which is relatively high in condensing temperature or relatively small in supercooling degree in the heat pump drying system with deep supercooling is provided with a subcooler, and a liquid refrigerant out of the condenser is cooled by means of dehumidified low-temperature air, so that the supercooling degree is improved greatly and the refrigerating capacity is improvedgreatly. When the plurality of subcoolers are adopted, the subcoolers can be connected in parallel or in series on the air side. In the system, drying air is successively cooled and dehumidified stageby stage by the evaporators and is then reheated by means of the condensers, so that the air is cooled and heated gradiently, and the heat pump drying system has the advantages of being small in heattransfer temperature difference, energy-saving and efficient.

Owner:QINGDAO UNIV +2

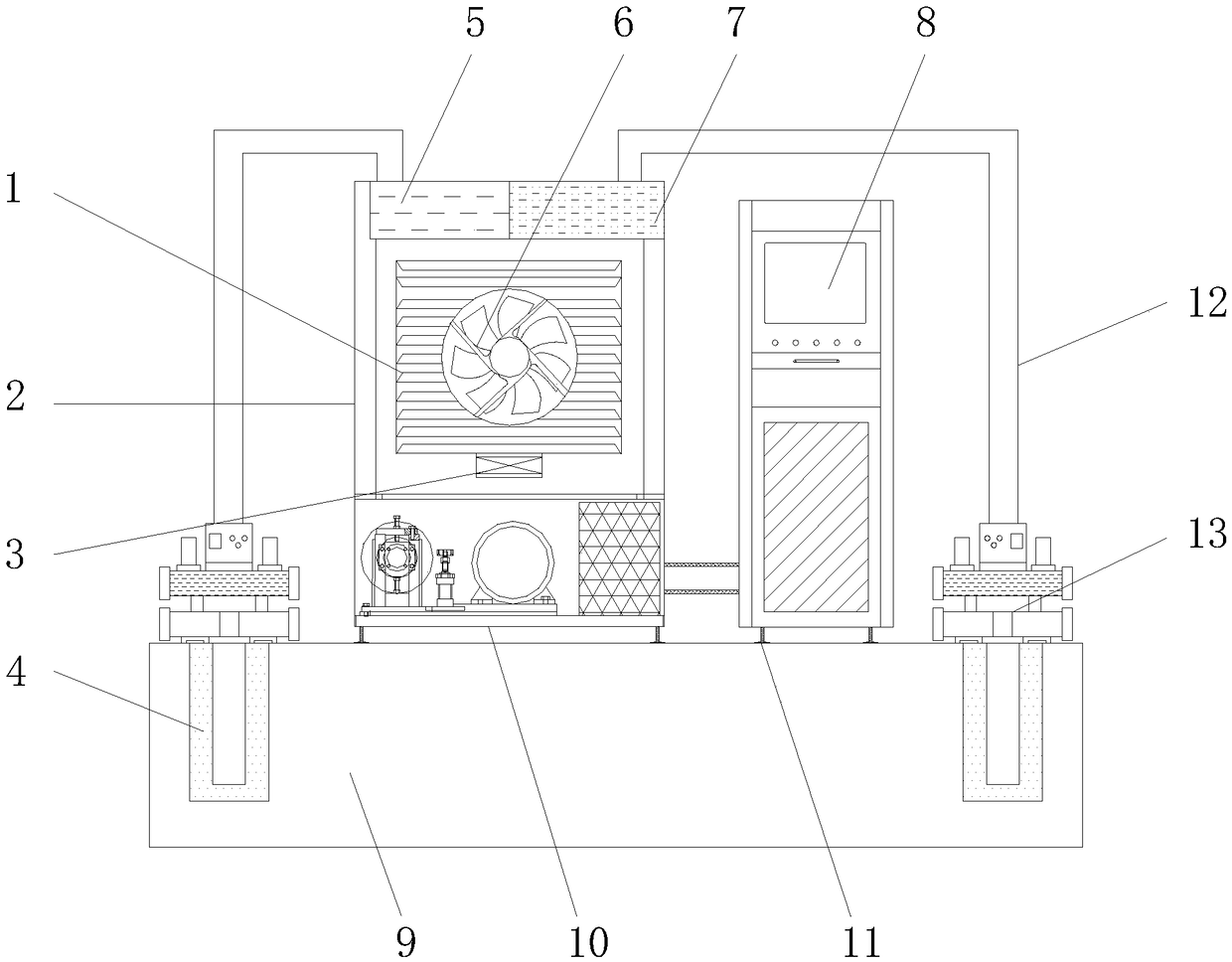

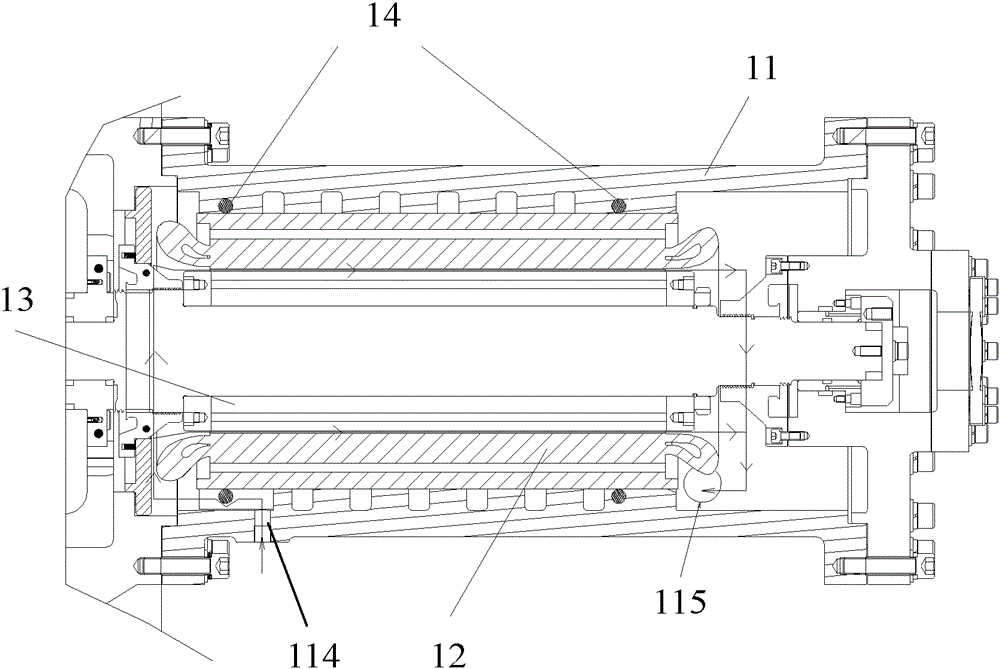

A subway train air conditioning unit with an exhaust air subcooler

InactiveCN105716334BImprove operational reliabilityImprove cooling efficiencyMechanical apparatusSubcoolersAir conditioningRefrigeration

The invention relates to an air-conditioning unit for subway trains with an exhaust supercooler. The air-conditioning unit includes a refrigerant circuit and an air circuit; the refrigerant circuit is filled with refrigerant, including a compressor, a condenser, and a throttling device. and an evaporator, the refrigerant circuit also includes a subcooler, wherein the compressor, condenser, subcooler, throttling device and evaporator are sequentially connected in a cycle; the air circuit includes an evaporator air circuit, an overcooler cooler air circuit and condenser air circuit. Compared with the prior art, the present invention uses the exhaust air of the compartment for cooling without consuming additional energy, and adds a subcooler to increase the cooling efficiency of the air conditioning unit. Simulation results show that after adding the subcooler, the refrigeration performance system 9% improvement.

Owner:TONGJI UNIV

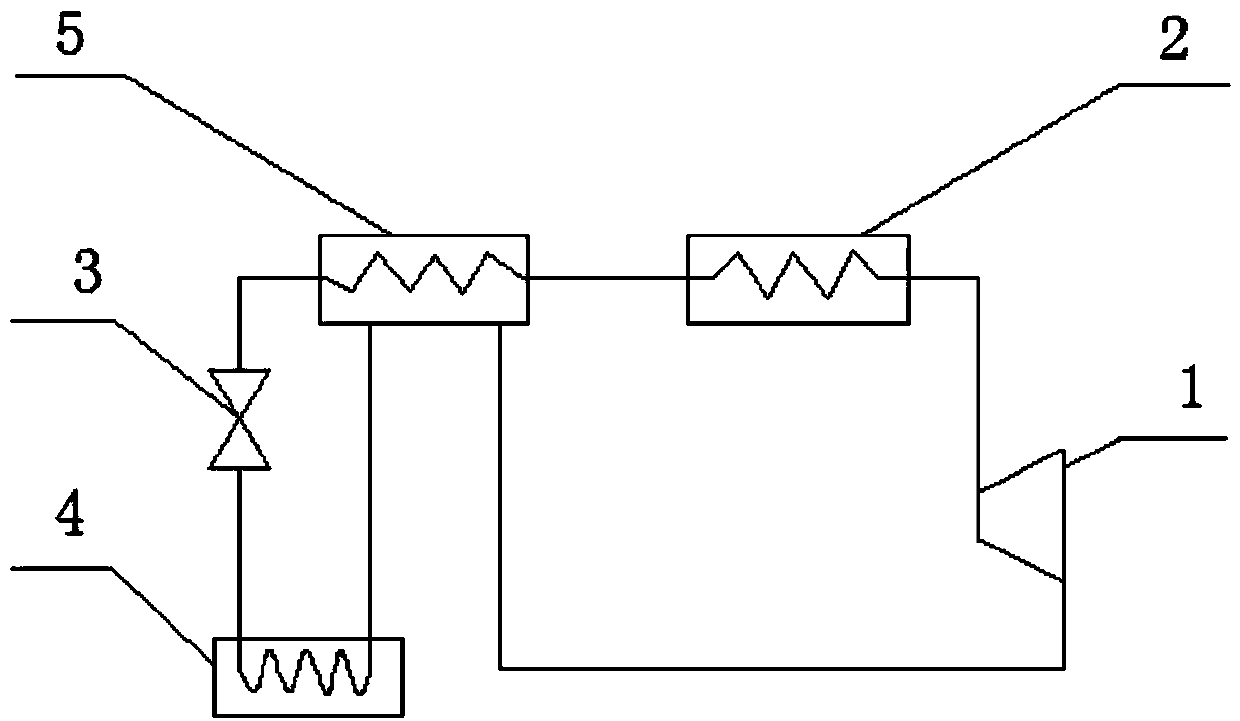

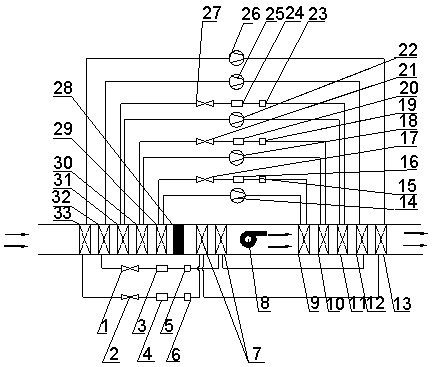

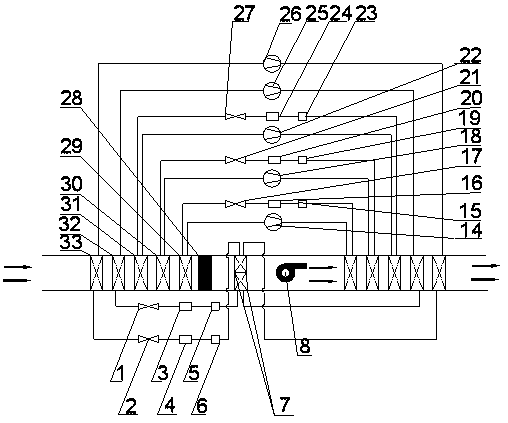

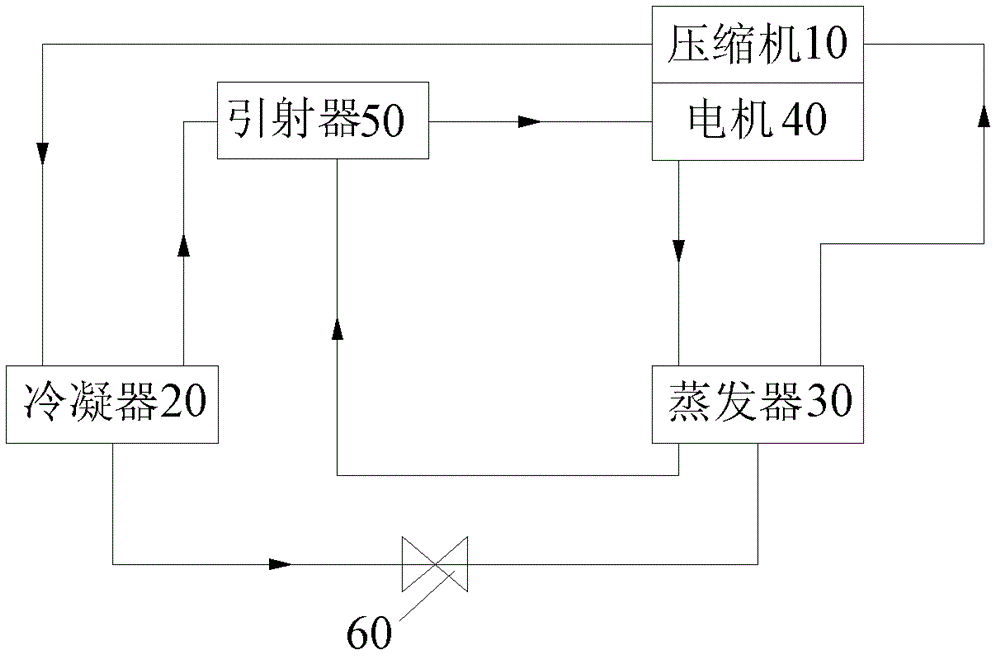

Refrigeration system and air conditioner

ActiveCN103322729BReduce energy lossIncrease unit cooling capacityCompressorMechanical apparatusEngineeringHigh pressure

The invention provides a refrigeration system and an air conditioner. The refrigeration system comprises a compressor, a condenser, a throttling device and an evaporator which are arranged sequentially; the refrigeration system further comprises a motor cooling loop; the motor cooling loop comprises a mixing injector which is arranged between the condenser and the evaporator; the mixing injector mixes a high-temperature high-pressure cooling medium from the condenser and a low-temperature low-pressure cooling medium from the evaporator into a mixed cooling medium and ejects the mixed cooling medium to a cavity of the motor of the compressor; and the mixed cooling medium cools the motor and then flows into the evaporator. According to the refrigeration system, the refrigeration capacity per unit is increased, the refrigeration cycle coefficient is increased, and an energy-saving effect is realized further; and at the same time, the refrigeration system can operate more stably.

Owner:GREE ELECTRIC APPLIANCES INC

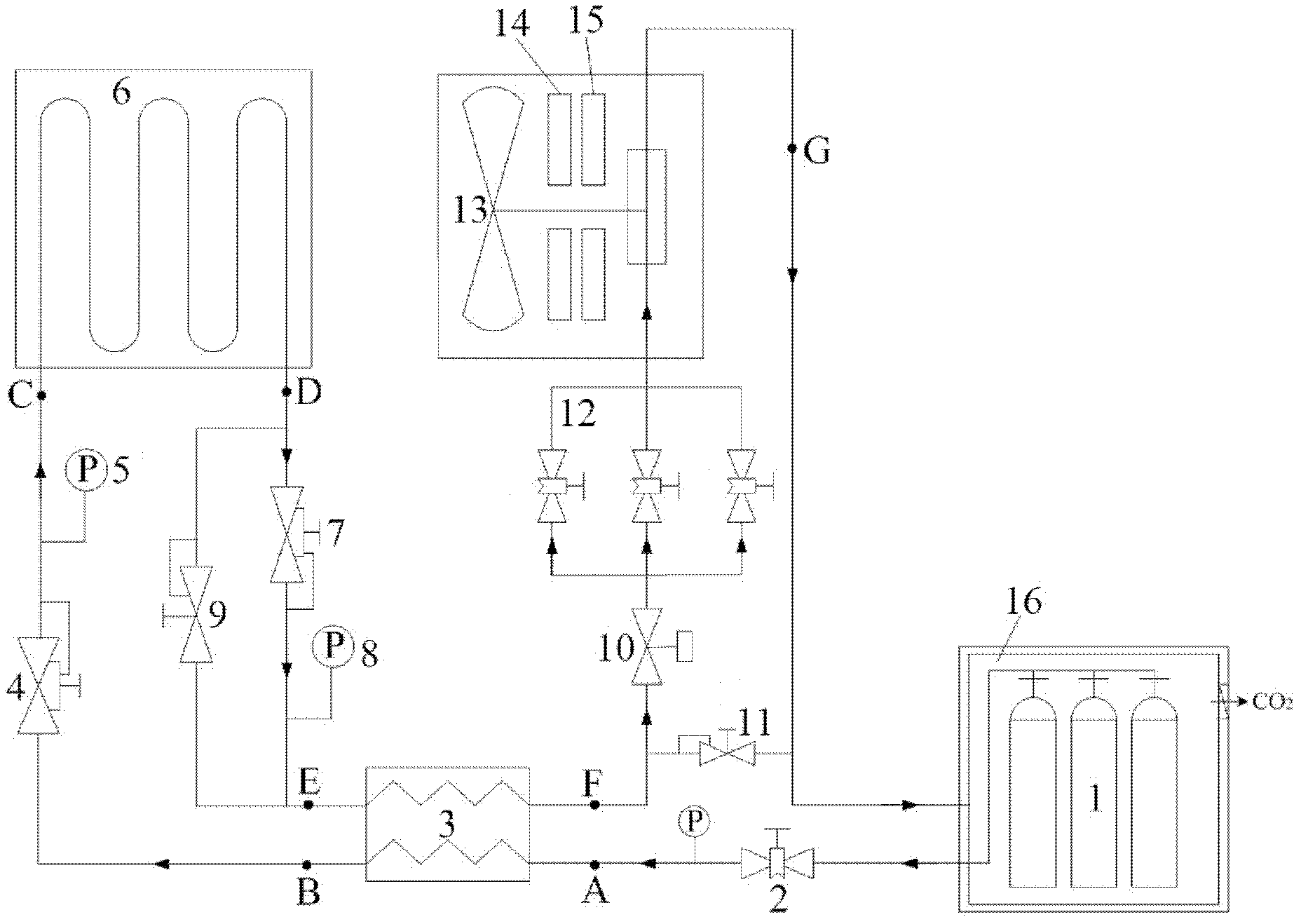

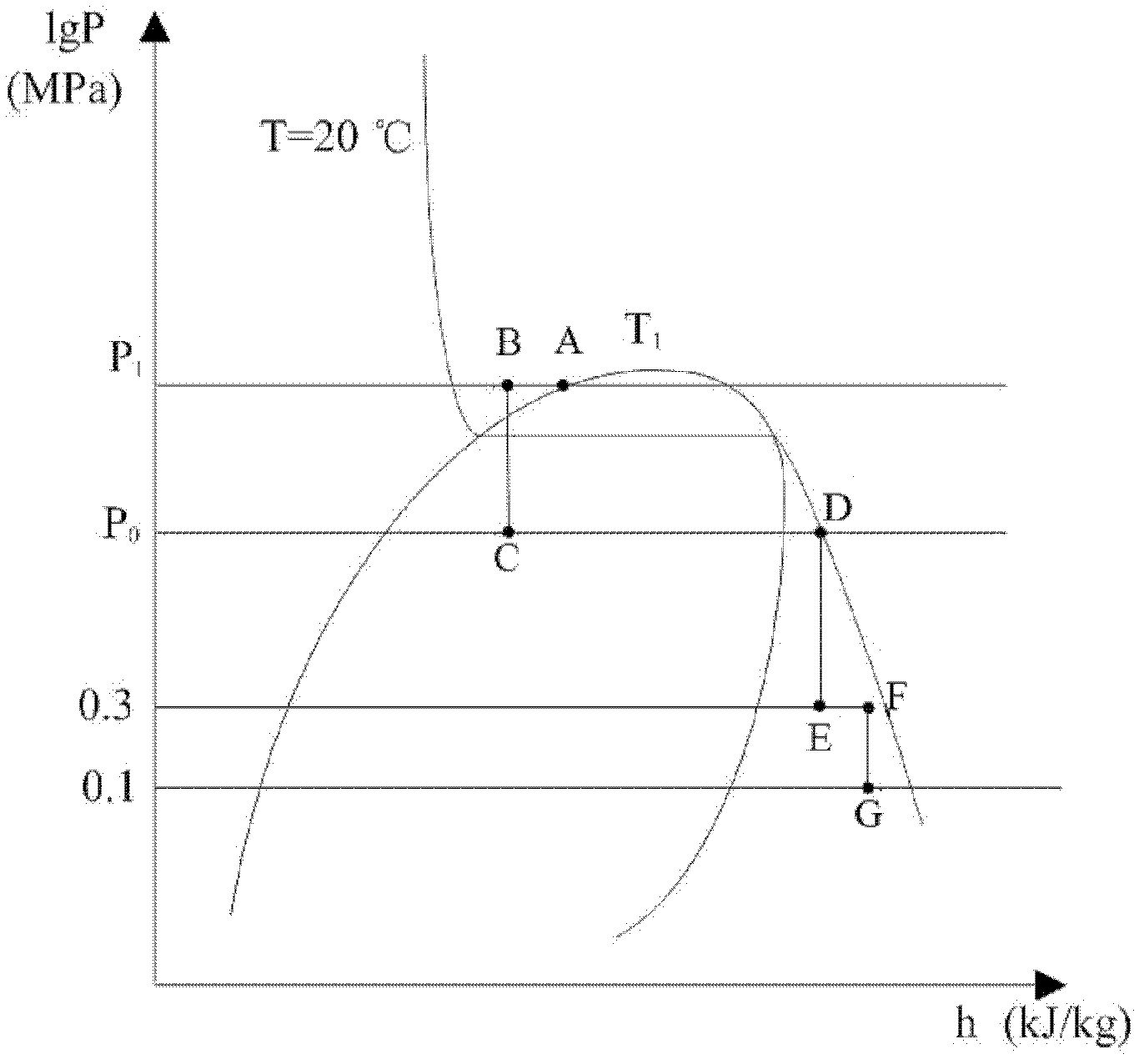

Frostless-air cooling and dehumidification system and method

InactiveCN102392673BSolve frostingControl refrigeration temperatureTunnel/mines ventillationSafety equipmentsTemperature controlCo2 storage

The invention relates to a frostless-air cooling and dehumidification system and a method. The system comprises CO2 liquid storage tanks, a manual valve, a regenerator, a first constant-pressure valve, a cooling evaporator, a second constant-pressure valve, an electromagnetic valve, a graded temperature control valve bank, a pneumatic fan, CO adsorbent, CO2 adsorbent and a CO2 storage room, liquid CO2 is throttled and cooled for two times after cold energy is recovered by the preposed regenerator, so that the evaporator cannot be frosted and the cold energy can be prerecovered, the graded temperature control valve bank regulates the flow of the CO2 in the cooling and dehumidification system by grading, so that the evaporation capacity of the cooling evaporator and the refrigerating output of the cooling and dehumidification system can be controlled and the system load and the temperature in an escape capsule can be regulated by grading, the pneumatic fan drives the air in the escape capsule to circulate, and thereby the environment in the escape capsule can be controlled in conditions suitable for living.

Owner:SOUTHEAST UNIV

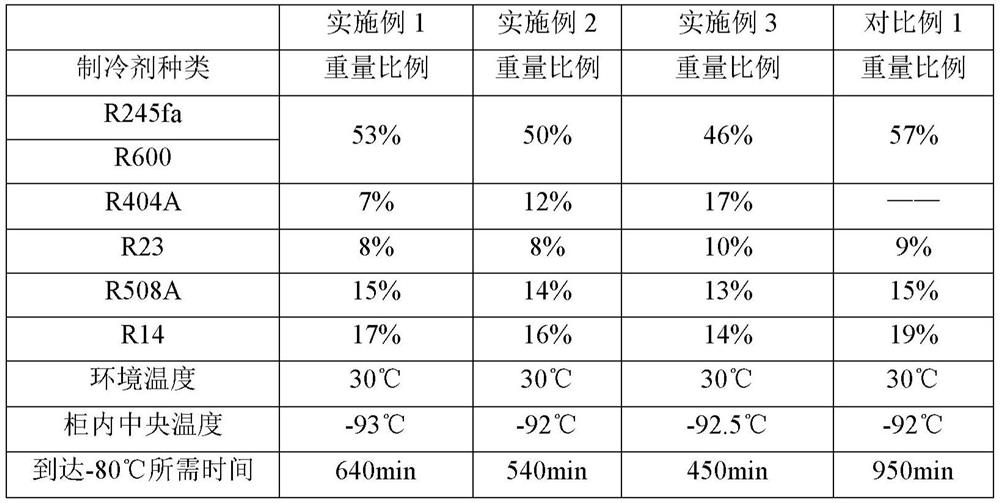

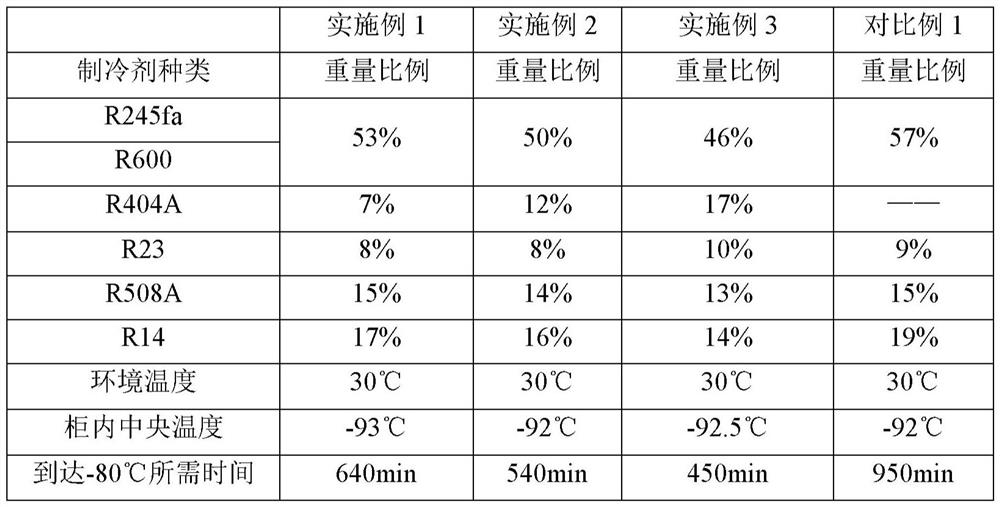

Mixed refrigerant and refrigerating system

ActiveCN114058334AImprove cooling effectConducive to separation cycleCompression machines with cascade operationHeat-exchange elementsThermodynamicsIcebox

The invention relates to a mixed refrigerant and a refrigerating system. The mixed refrigerant comprises the following components: a non-azeotropic mixed refrigerant containing R245fa, R600, R404A, R23 / R116, R508A / R508B and R14, the mixed refrigerant is used in an auto-cascade refrigerating system, and the ultralow temperature in a large-volume refrigerator and a large-volume freezer cabinet can reach -90 DEG C or below.

Owner:冰山松洋生物科技(大连)有限公司

Motor and air conditioner including the motor

ActiveCN103312087BReduce consumptionReduce energy lossLighting and heating apparatusCooling/ventillation arrangementEngineeringRefrigeration

The invention provides a motor and an air conditioner comprising the same. The motor is provided with a main shaft, a water inlet, a water outlet, a water channel, a refrigerant inlet and a refrigerant outlet, wherein a rotor is sleeved outside the main shaft; a stator is sleeved outside the rotor; a casing is sleeved outside the stator; an air gap is formed between the rotor and the stator; the water inlet and the water outlet are arranged on the side wall of the casing; the water channel is arranged on the inner wall of the casing and / or the outer wall of the stator and surrounds the stator; both ends of the water channel are respectively connected with the water inlet and water outlet; and the refrigerant inlet and the refrigerant outlet are arranged on the side wall of the casing and are communicated with the air gap. When the motor and the air conditioner are used, the water inlet of the motor is communicated with a cooling water inlet of a condenser, the water outlet of the motor is communicated with a cooling water outlet of the condenser, the refrigerant inlet is communicated with an air escaping pipe of a flash evaporator, and the refrigerant outlet is communicated with an evaporator. According to the motor and the air conditioner, the energy loss during the throttling depressurization caused by an existing cooling scheme is reduced, the consumption of refrigerating output is reduced, the refrigeration circulating coefficient is improved, and the effect of energy saving is achieved, so that the device works more stably and reliably.

Owner:GREE ELECTRIC APPLIANCES INC

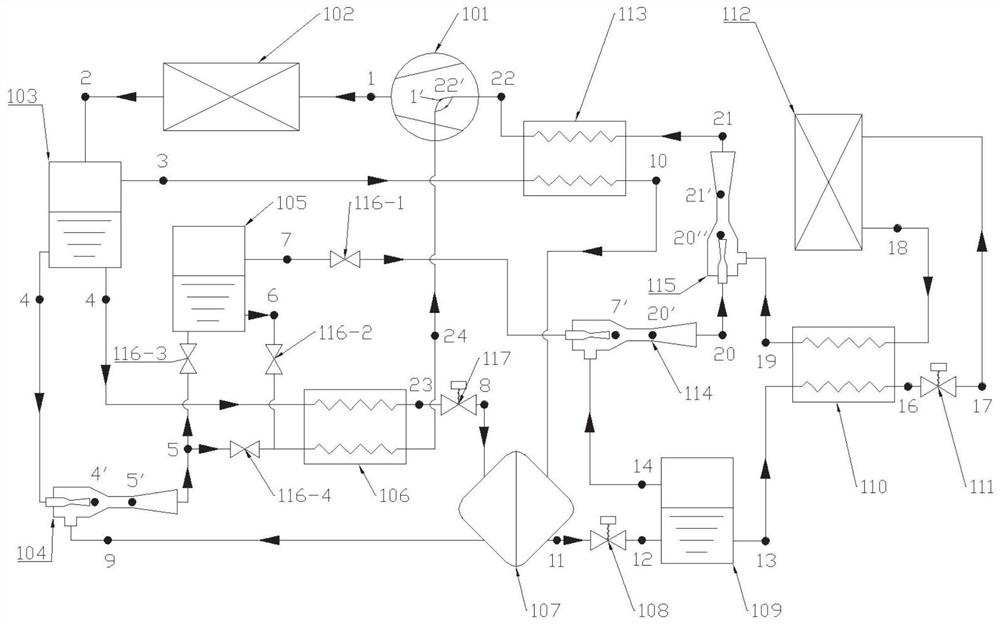

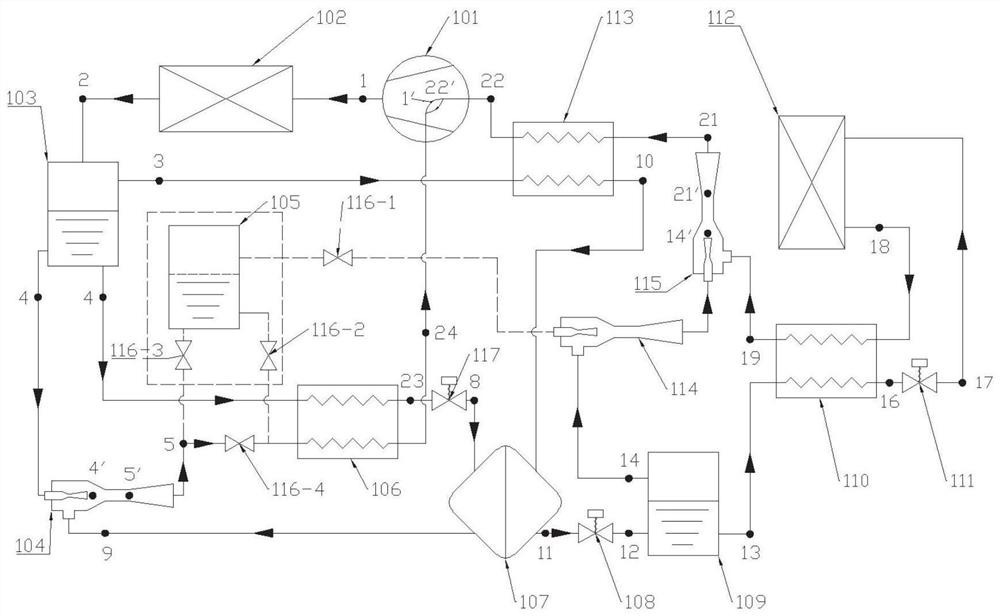

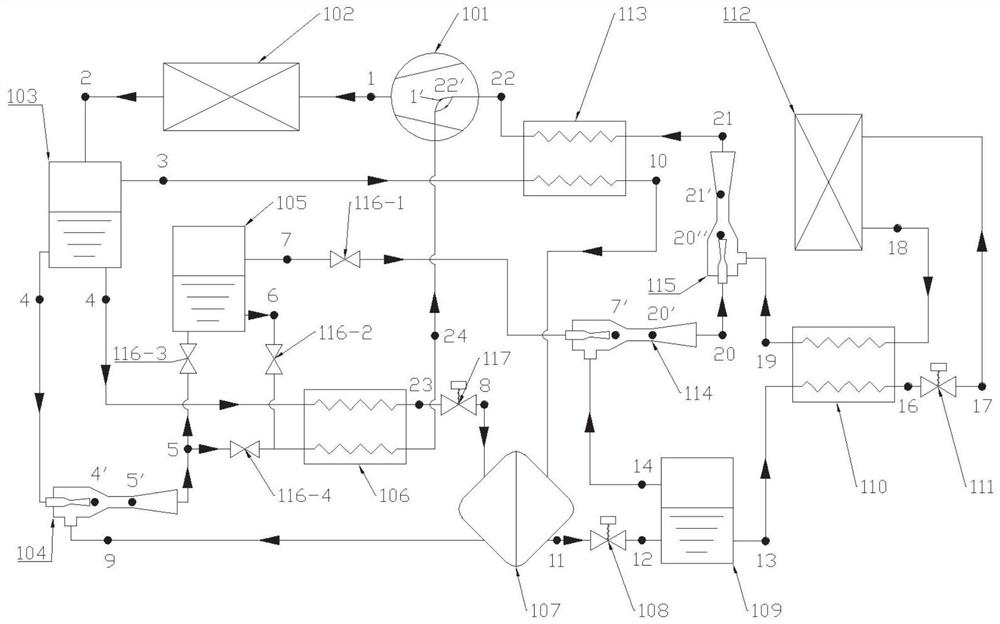

An electric vehicle air conditioning system

ActiveCN103129349BAvoid failureIncrease unit cooling capacityAir-treating devicesVehicle heating/cooling devicesPlate heat exchangerAutomobile air conditioning

The invention discloses an electric vehicle air conditioner system which comprises a refrigerant circulation loop and a coolant circulation loop. The refrigerant circulation loop comprises a compressor for compressing refrigerant, a valve or a valve assembly for switching a refrigerant flow path, a heat exchanger outside a carriage, a heat exchanger in the carriage and a throttle assembly in pipeline connection between the heat exchanger outside the carriage and heat exchanger inside the carriage. The refrigerant circulation loop comprises an electric water pump in pipeline connection, a first double flow channel heat exchanger and at least one fifth heat exchanger. The electric vehicle air conditioner system further comprises a second double flow channel heat exchanger in pipeline connection at an entrance side of a throttle device in the throttle assembly. The electric vehicle air conditioner system can not only prevent cooling devices like a battery from losing effect due to supercooling of coolant, and refrigerating capacity per unit of the electric vehicle air conditioner system can be improved.

Owner:SANHUA HLDG GRP

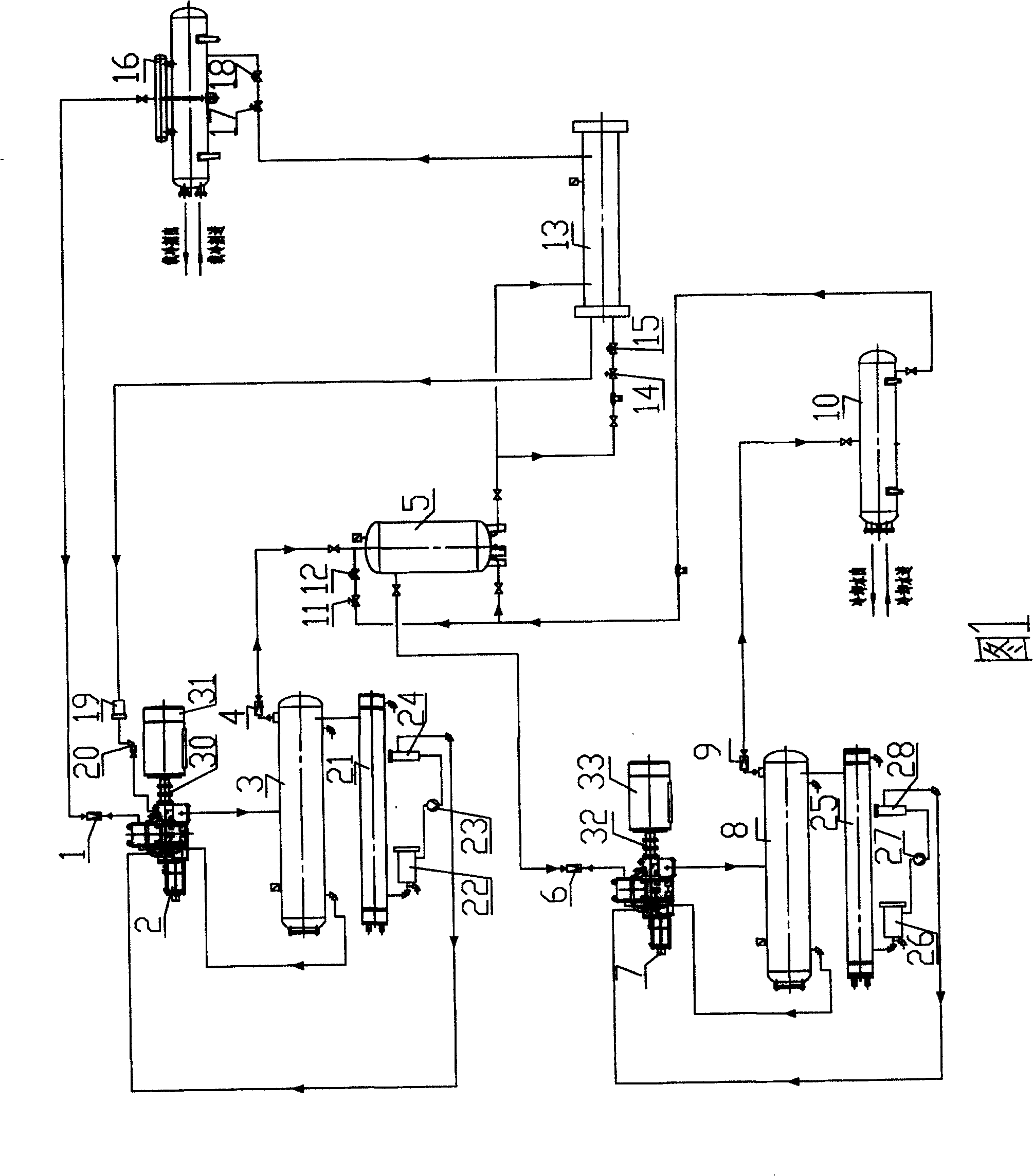

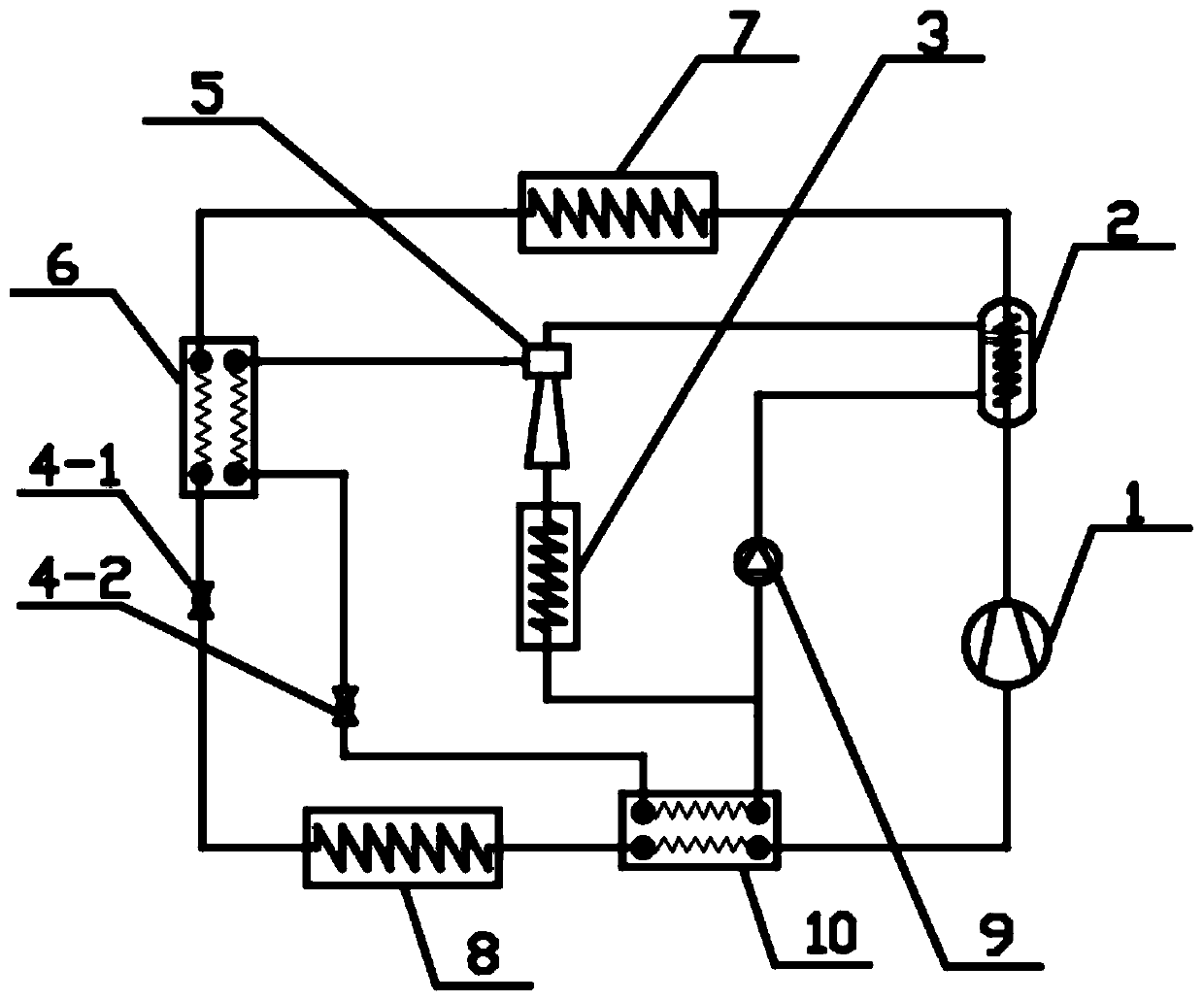

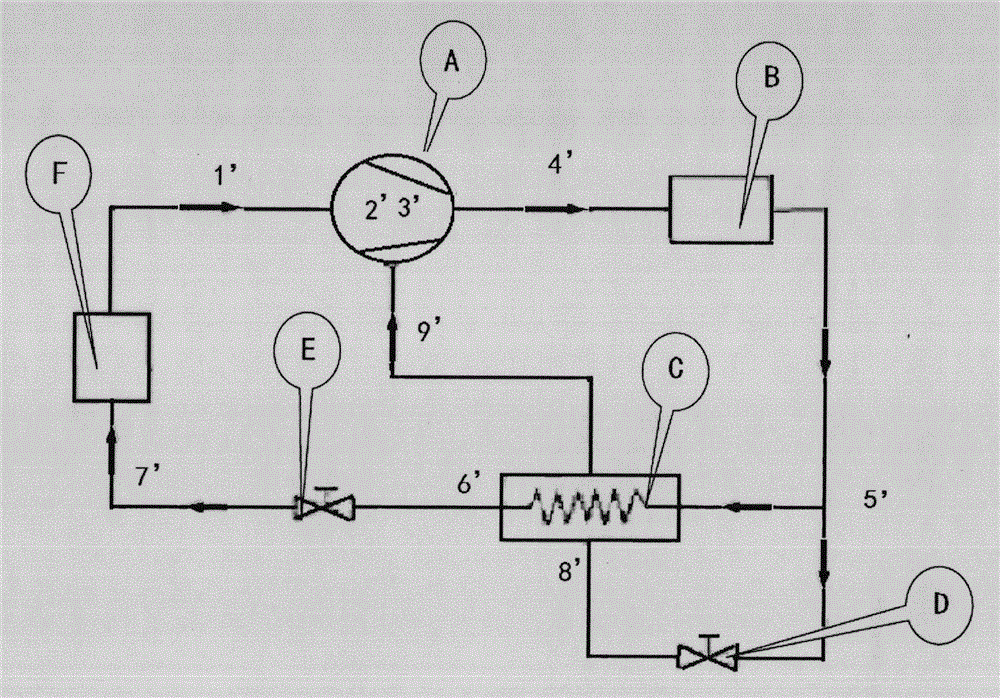

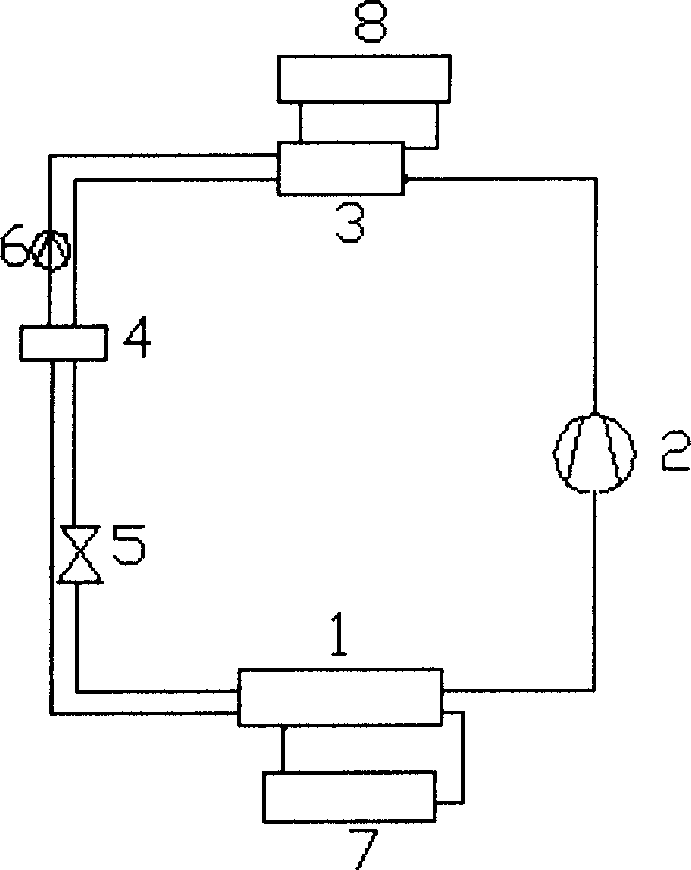

Circulating device combining diffusing absorption-type refrigeration and vapor compression refrigeration

InactiveCN102322705BReduce condensationImprove area utilizationRefrigeration machinesEngineeringVapor-compression refrigeration

The invention provides a circulating device combining diffusing absorption-type refrigeration and vapor compression refrigeration. The circulating device is characterized by comprising a compressor (1), a generator (2), a first condenser (3), a throttling valve (4), a first evaporator (5), a second condenser (6), a second evaporator (7), a gas heat exchanger (8), an absorption device (9), a liquid storage device (10), a liquid heat exchanger (11) and a hydrogen tank (12); a vapor compression refrigeration circulating side and the exhaust port of the compressor (1) are connected with the inlet of the heat exchanger; the outlet of the heat exchanger is connected with the inlet of the first condenser (3); the outlet pipeline of the first condenser (3) is connected with the inlet of the throttling valve (4) through the second evaporator (7); the outlet of the throttling valve (4) is connected with the inlet of the first evaporator (5); and the outlet of the first evaporator (5) is connected with an air suction port of the compressor. According to the invention, the refrigeration coefficient of the refrigerating system can be improved.

Owner:SOUTHEAST UNIV

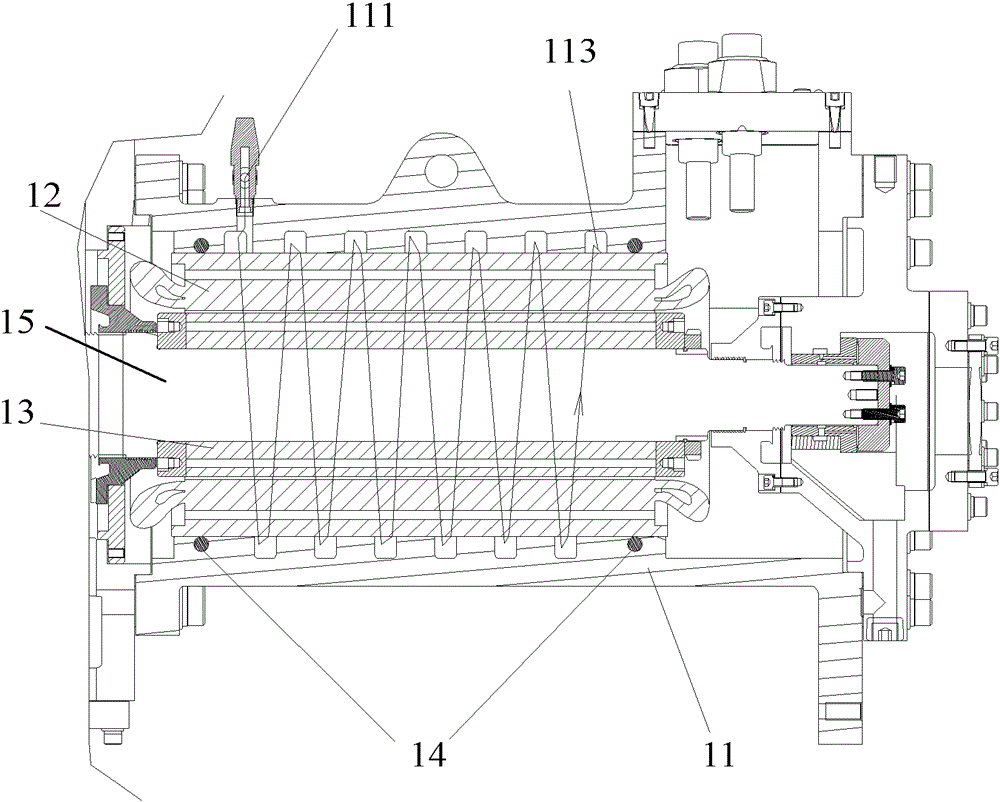

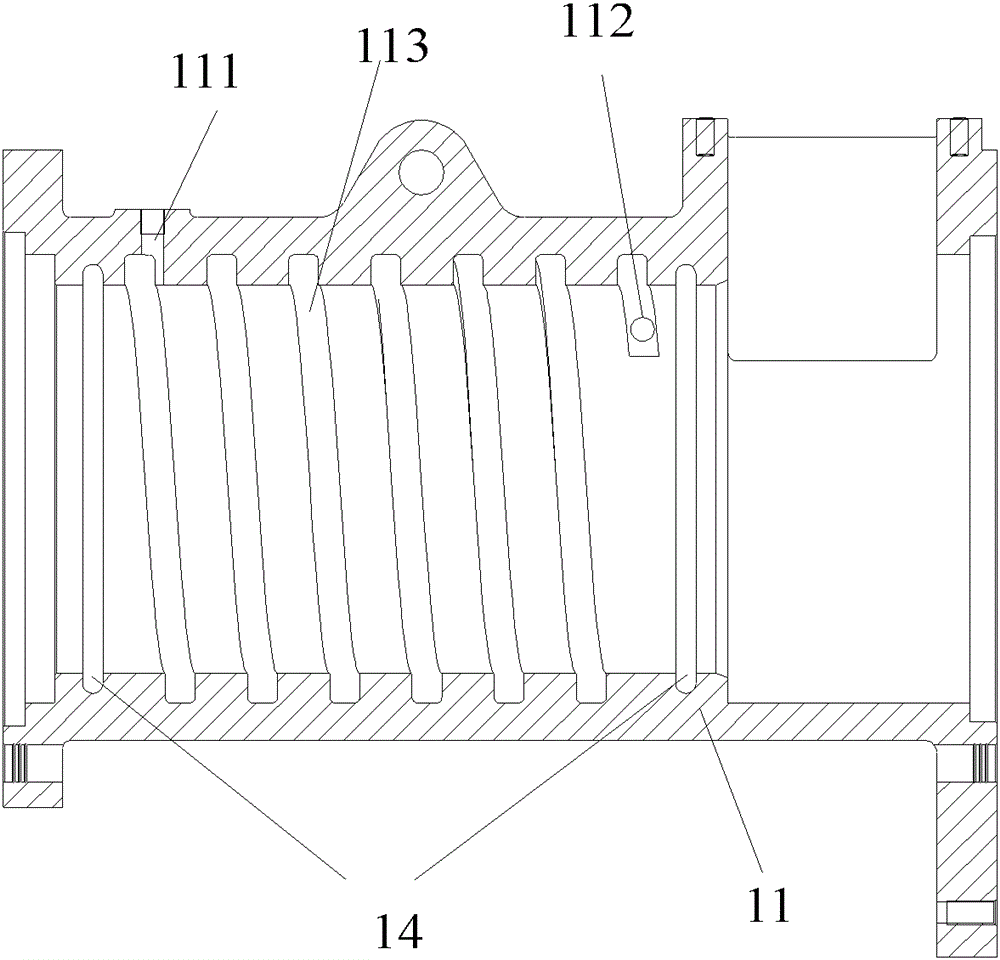

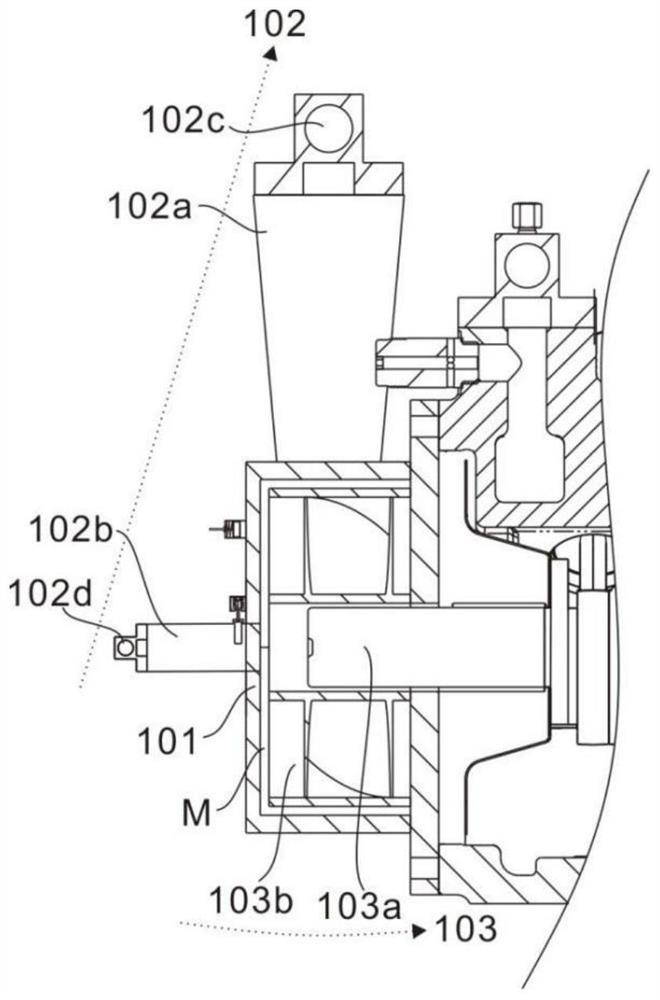

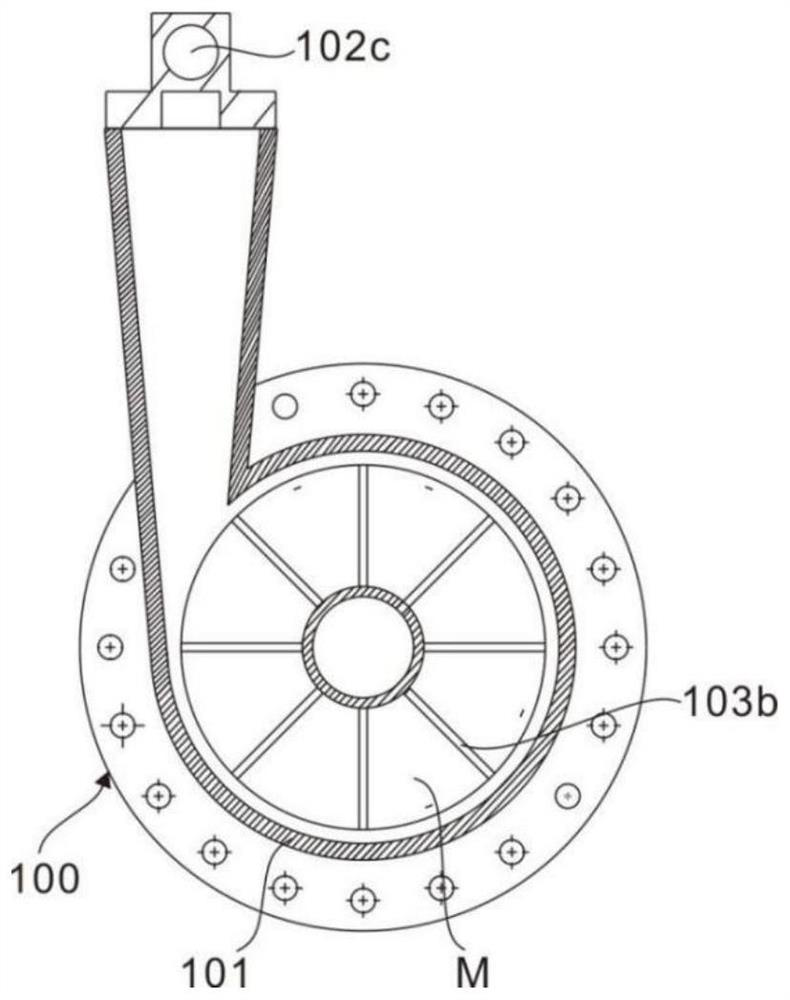

CO2 refrigeration piston compressor with turbine expansion mechanism

ActiveCN113550801AReduce consumptionImprove protectionPositive displacement pump componentsEfficient regulation technologiesElectric machineEngineering

The invention discloses a CO2 refrigeration piston compressor with a turbine expansion mechanism. The CO2 refrigeration piston compressor comprises an expansion unit and a compression unit, wherein the expansion unit comprises an expansion shell, a gas channel and an acting assembly, the acting assembly comprises a transmission part and a rotating part, and the rotating part is arranged in the expansion shell and connected with the transmission part; and the compression unit comprises a motor, a connecting rod, a piston and an air cylinder. According to the CO2 refrigeration piston compressor, the acting assembly is coaxially connected with the motor, and normal-temperature high-pressure CO2 gas expands in the expansion shell to act outwards, so that power consumption of the motor is saved; and meanwhile, the dryness of the high-pressure CO2 in the fluid state after isentropic expansion is smaller than that of the high-pressure CO2 in the fluid state after adiabatic throttling, and therefore the unit refrigerating capacity is improved; According to a system applying the CO2 refrigeration piston compressor, the motor power in the working process of the compressor is reduced, the refrigerating capacity of the system is increased, and therefore the operation energy efficiency of the system is improved.

Owner:南京久鼎环境科技股份有限公司

High-efficiency vehicle electric cooling and heating air heat exchange system

ActiveCN103591733BReduce exhaust temperatureLarge displacementCompressorMechanical apparatusEngineeringMechanical engineering

The invention relates to a high-efficiency vehicle electric cooling and heating air heat exchange system, comprising a scroll electric compressor, an external heat exchanger, an interior heat exchanger and an economizer; the scroll electric compressor has an auxiliary suction port, and the refrigerant liquid After flowing out from the external heat exchanger, it is divided into two paths: the first refrigerant liquid is supercooled after exchanging heat in the economizer, enters the internal heat exchanger after passing through the electronic expansion valve, and is finally electrically compressed by the vortex The second path enters the economizer after passing through the electronic expansion valve, and turns into gas after cooling the first path refrigerant liquid, and finally enters the scroll electric compressor through the auxiliary suction port. The heat exchange system of the present invention can effectively solve many problems such as insufficient heating and excessively high discharge temperature of the compressor under low temperature conditions.

Owner:江苏晨宇科技有限公司

Solution desorption refrigeration circulation device

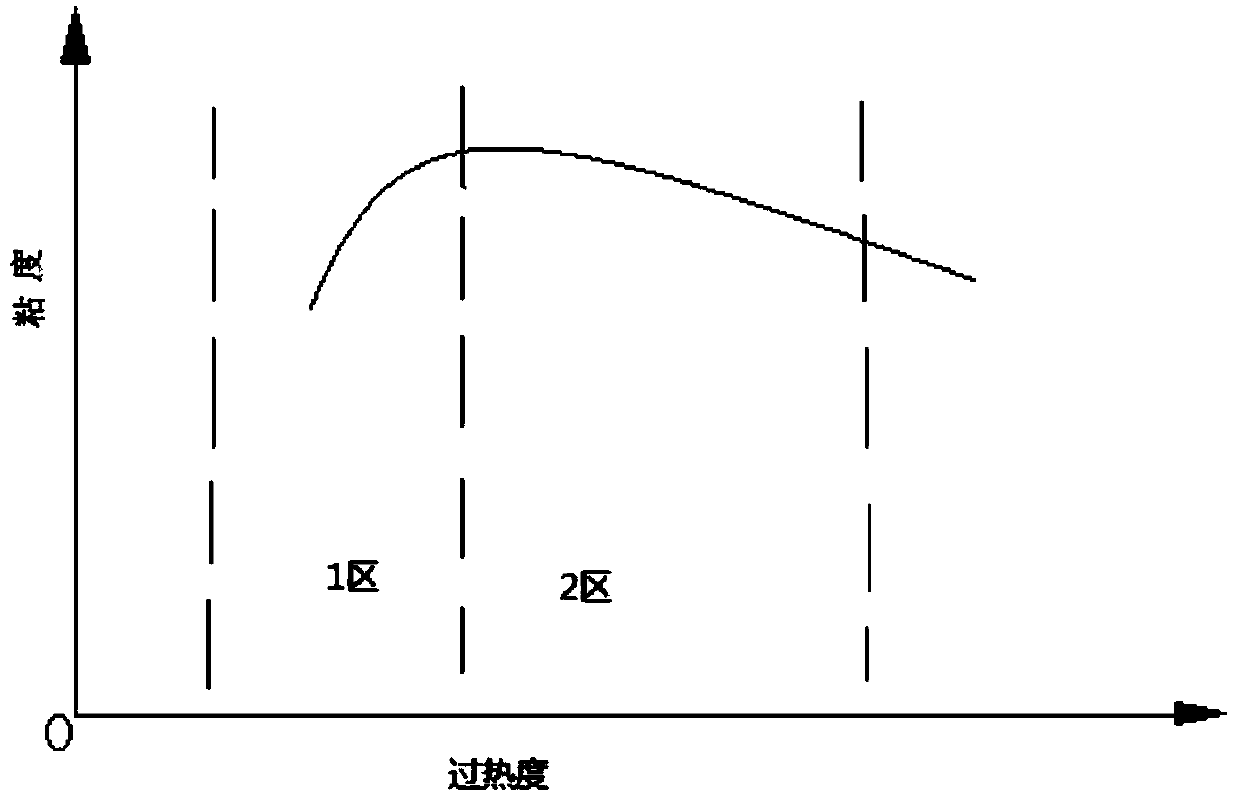

InactiveCN1828180AIncrease unit cooling capacityImprove the cooling factorEnergy efficient heating/coolingClimate change adaptationDesorptionEngineering

The invention relates to a solution desorption refrigeration cycle device, which is characterized in that: it has a low-pressure generator, which has a outlet via channel connected to the inlet, and a inlet via channel connected to the throat valve and the heat exchanger, while another outlet via channel is connected to the inlet of heat exchanger and another two interfaces via channels connected to the inlet and outlet of low-temperature heat base; one inlet of adsorbed via channel is connected to the outlet of compressor, while another outlet is connected to the solution pump; another two interfaces of adsorbed via channel is connected to the inlet and outlet of high-temperature heat base. The invention uses solution to generate desorption in low-temperature to generate the refrigerator, which can attain higher unit refrigerator than steam compress refrigeration cycle device, with improved refrigeration factor.

Owner:OCEAN UNIV OF CHINA

Mixed refrigerants and refrigeration systems

ActiveCN112195015BImprove cooling effectConducive to separation cycleCompression machines with cascade operationHeat-exchange elementsIceboxEngineering

A mixed refrigerant and a refrigeration system, the mixed refrigerant includes the following composition: a zeotropic mixed refrigerant containing R245fa, R600, R404A, R23 / R116, R508A / R508B, R14, which is used in a self-cascading refrigeration system Use, can make its large-capacity refrigerators and freezers reach ultra-low temperatures below -90°C.

Owner:冰山松洋生物科技(大连)有限公司

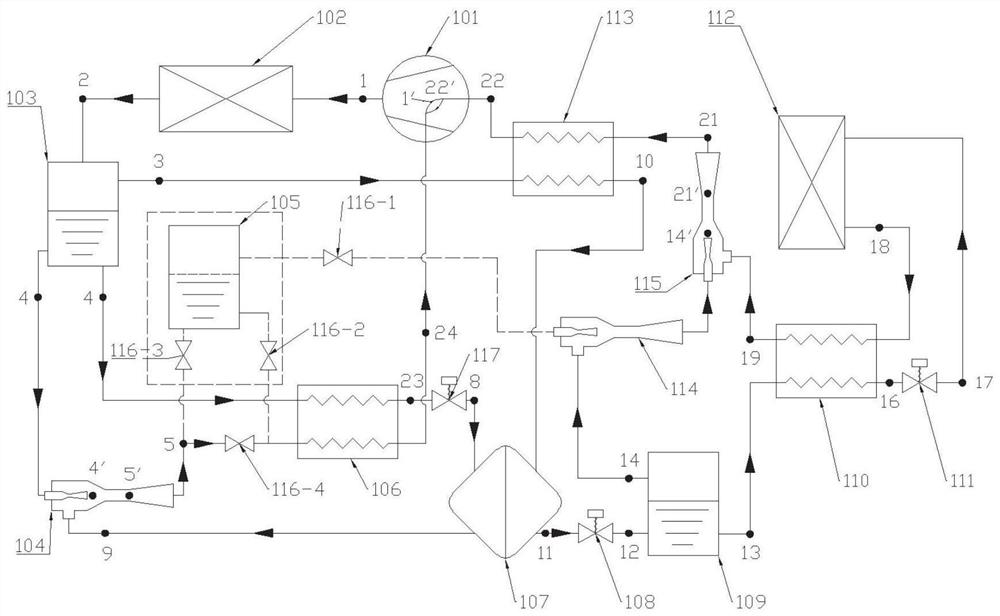

A Quasi-two-stage Compression Circulation System with Ejector Boost

ActiveCN113899095BRealize QiAbility to operate under variable conditionsMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention relates to a quasi-two-stage compression cycle system with ejector synergies, which is a self-cascade compression refrigeration cycle system, including a compressor connected to a condenser, the condenser connected to a first gas-liquid separator, One liquid outlet of the first gas-liquid separator is connected to the first ejector, and the first ejector is connected to the gas supply port of the compressor through the superheated side of the first regenerator, and the other liquid outlet of the first gas-liquid separator is in turn The subcooling side of the first regenerator and the depressurization cooling element are connected to the inlet of the evaporation side of the evaporative condenser, the outlet of the evaporation side is connected to the secondary flow inlet of the first ejector, and the gas outlet of the first gas-liquid separator The evaporator is connected to the evaporator through the second regenerator, the condensation side of the evaporative condenser, the second gas-liquid separator and the third regenerator, and the evaporator is connected to the evaporator through the third regenerator, the second ejector and the second regenerator Connected with the suction port of the compressor, the system of the present invention has strong ability to adapt to variable working conditions and has small throttling loss.

Owner:SHANDONG UNIV

Ejector enhanced quasi-two-stage compression type circulating system

ActiveCN113899095ARealize QiAbility to operate under variable conditionsMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention relates to an ejector enhanced quasi-two-stage compression type circulating system, which is an auto-cascade compression refrigeration circulation system and comprises a compressor, wherein the compressor is connected with a condenser; the condenser is connected with a first gas-liquid separator; one liquid outlet of the first gas-liquid separator is connected with a first ejector; the first ejector is connected with an air supply port of the compressor through a superheated side of a first heat regenerator; the other liquid outlet of the first gas-liquid separator is connected with an evaporation side inlet of an evaporative condenser through a supercooled side of the first heat regenerator and a depressurization and cooling element in sequence; an evaporation side outlet is connected with a secondary flow inlet of the first ejector; a gas outlet of the first gas-liquid separator is connected with the evaporator through a second heat regenerator, a condensation side of the evaporative condenser, a second gas-liquid separator and a third heat regenerator; and the evaporator is connected with an air suction port of the compressor through the third heat regenerator, a second ejector and a second heat regenerator. The system of the invention is high in variable working condition adapting capacity and small in throttling loss.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com