Dual-locomotive and dual-stage screw refrigerating compressor set

A technology of compressor units and compressors, which is applied to refrigerators, compressors, compressors with cascaded work, etc., can solve the problems of paralysis of the refrigeration system, complicated installation and connection, and large motor power configuration of low-voltage stage compressors. Achieve the effect of reducing the power of the oil pump motor, facilitating flexible control, and saving energy in the operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

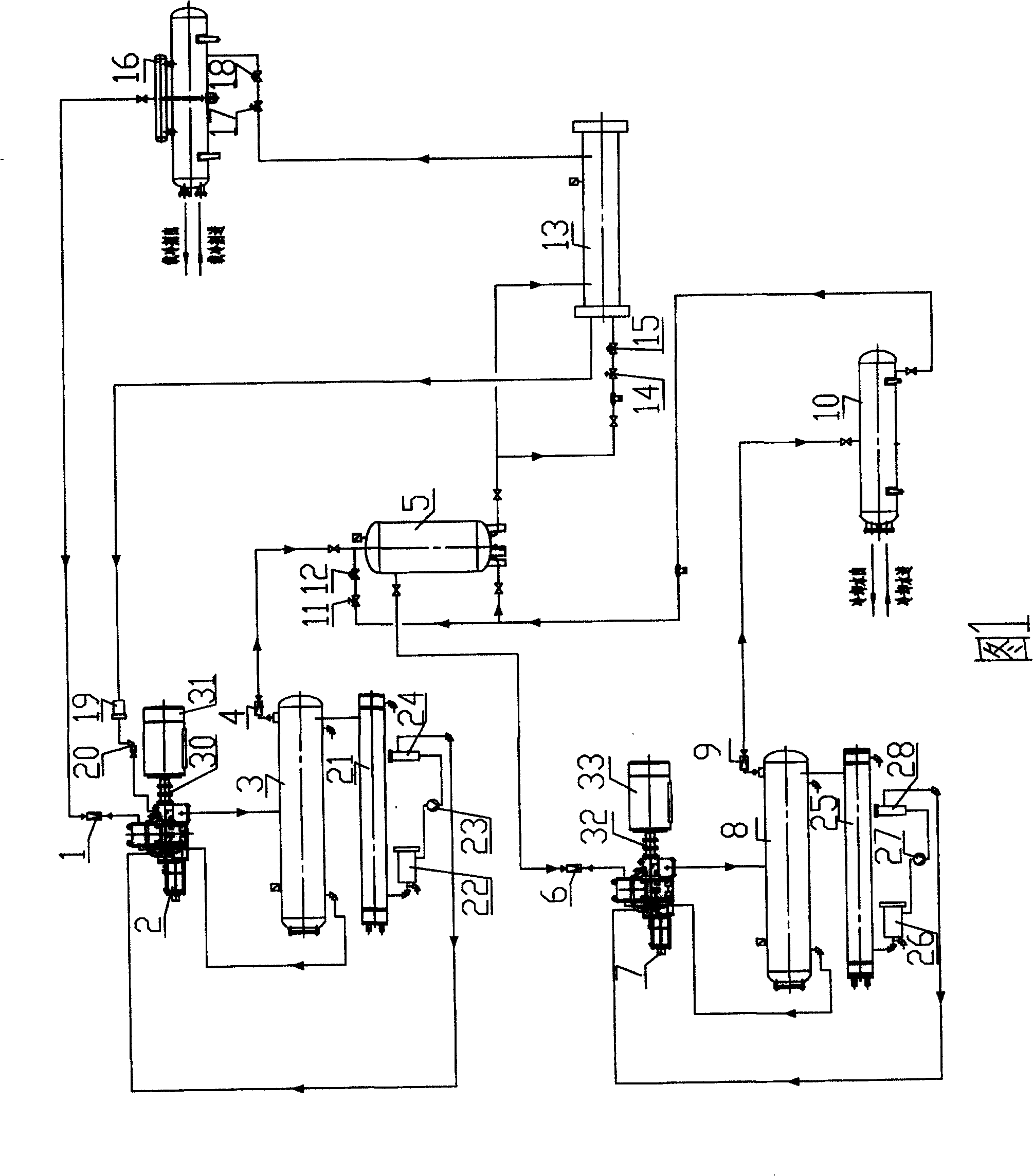

[0031] The structure and working process of the traditional two-stage screw refrigeration compression dispersion system shown in Fig. 1 have been described in detail in the previous section of the background technology, and will not be repeated here.

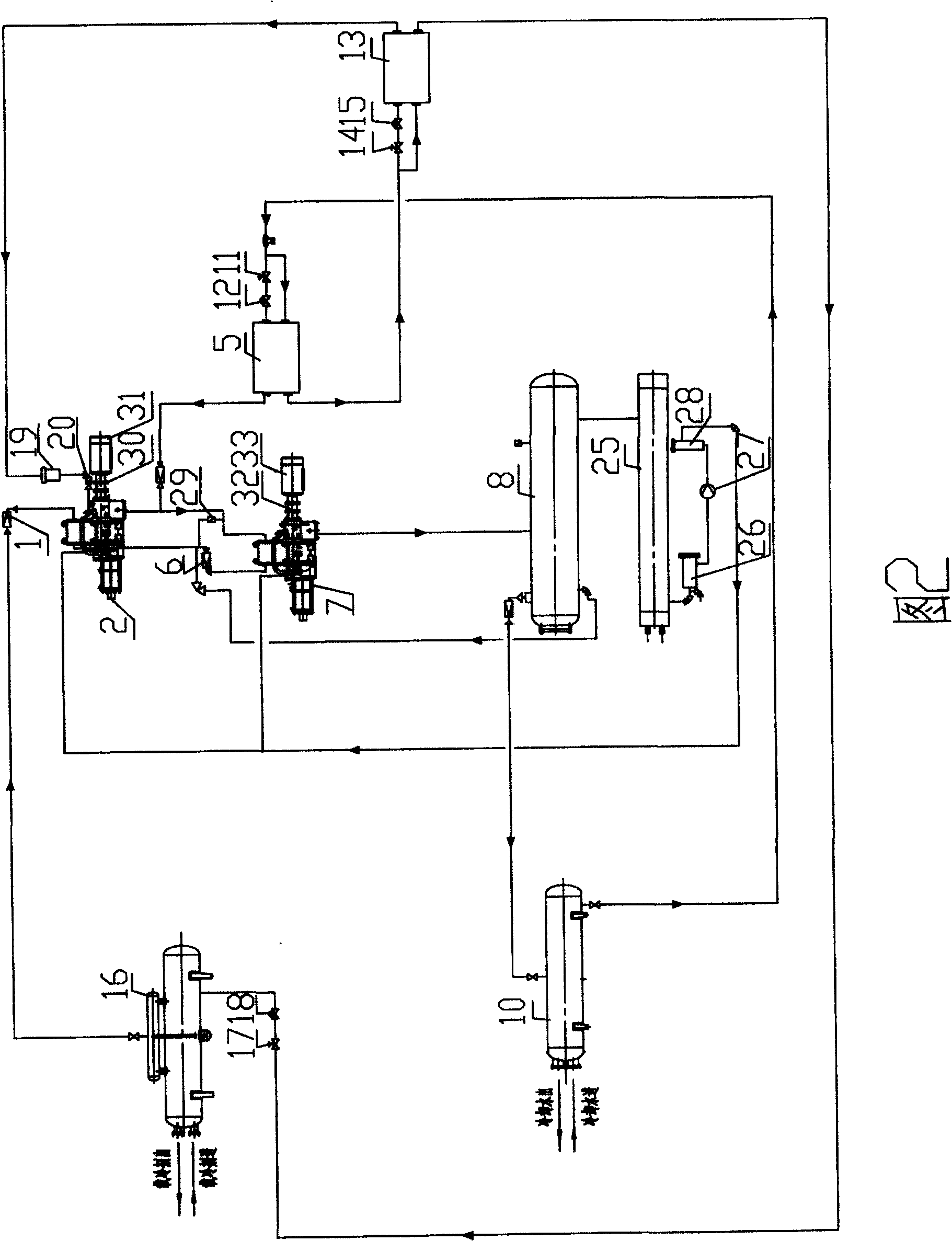

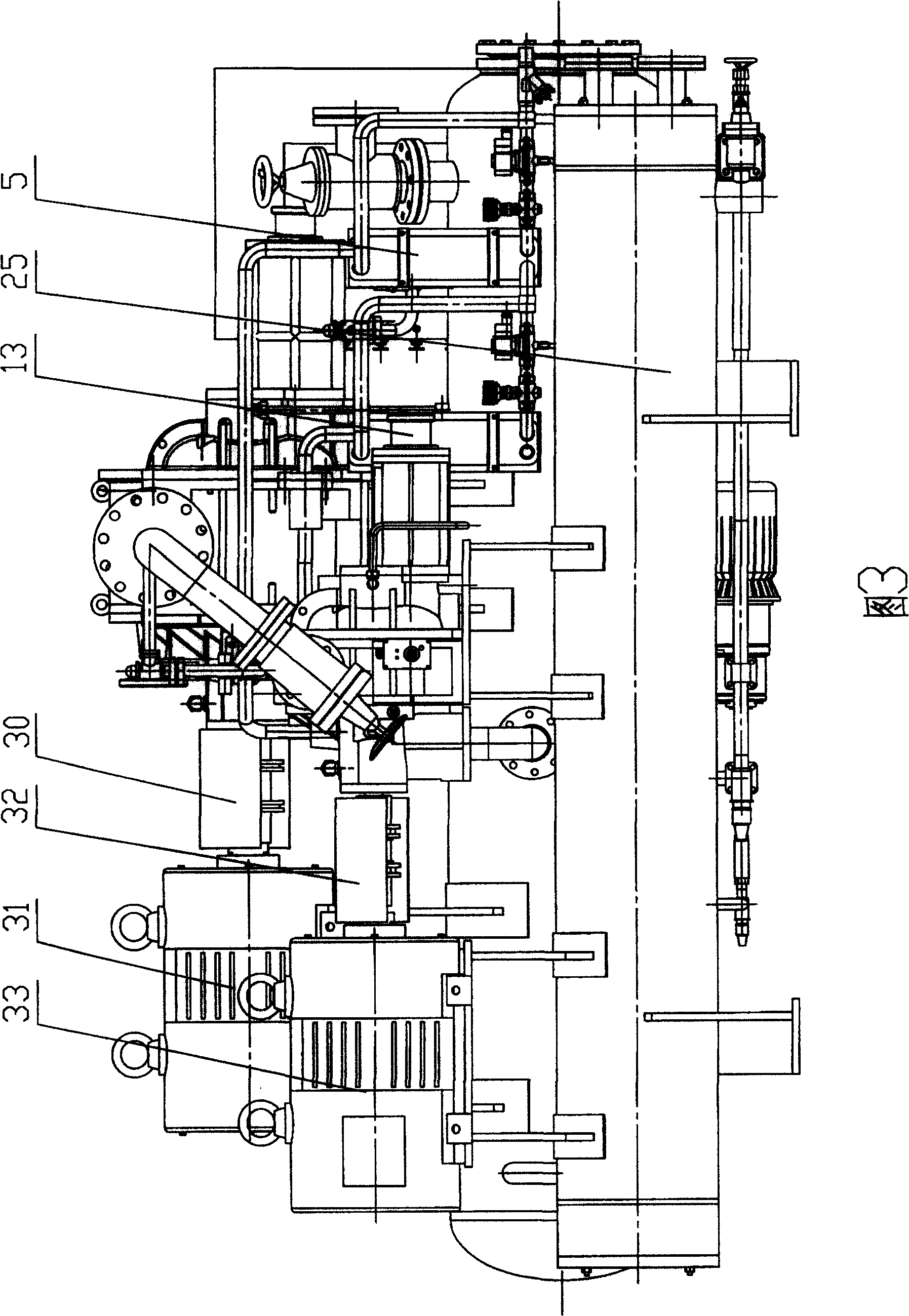

[0032] The two-machine two-stage screw refrigeration compressor unit shown in Figures 2 to 4 mainly consists of a low-pressure stage compressor 2, a high-pressure stage compressor 7, a horizontal oil separator 8, an oil cooler 25, and an oil compressor connected through pipelines and valves. Coarse filter 26, oil pump 27, olein filter 28, intercooler 5, low-pressure stage economizer 13, and microcomputer control box 34 etc. are composed. The low-pressure stage compressor 2 and its coupling 30 and the driving motor 31 are arranged on the oil separator 8, the high-pressure stage compressor 7 and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com