Nozzle of vortex tube

A technology of vortex tubes and nozzles, which is applied in the field of refrigeration, and can solve the problems of large energy loss, small unit cooling capacity, and low energy separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this implementation, compared with the existing common nozzles, only the profile line of the nozzle runner 1 is changed, as shown in the attached Figure 8 , with Figure 9 As shown, the nozzle 6 of the present invention is integrated with the cold end pipe 4 of the vortex tube, and as a replaceable part, it is loaded into the corresponding position of the vortex tube. The Mach number at the outlet of the nozzle flow channel is 0.57, and the Mach number at the inlet is 0.19.

[0048] Ordinary rectangular nozzle size: cold air hole diameter 5.6mm, vortex chamber diameter 13mm, nozzle outer circumference diameter 20mm, nozzle runner groove width L=2mm, nozzle runner groove depth H=1mm, nozzle material is plexiglass.

[0049] Archimedes spiral nozzle: the size and material are the same as ordinary rectangular nozzles

[0050] The size of the nozzle of the present invention: the groove width L at the inlet of the nozzle flow channel e =3mm, groove width L at the outle...

Embodiment 2

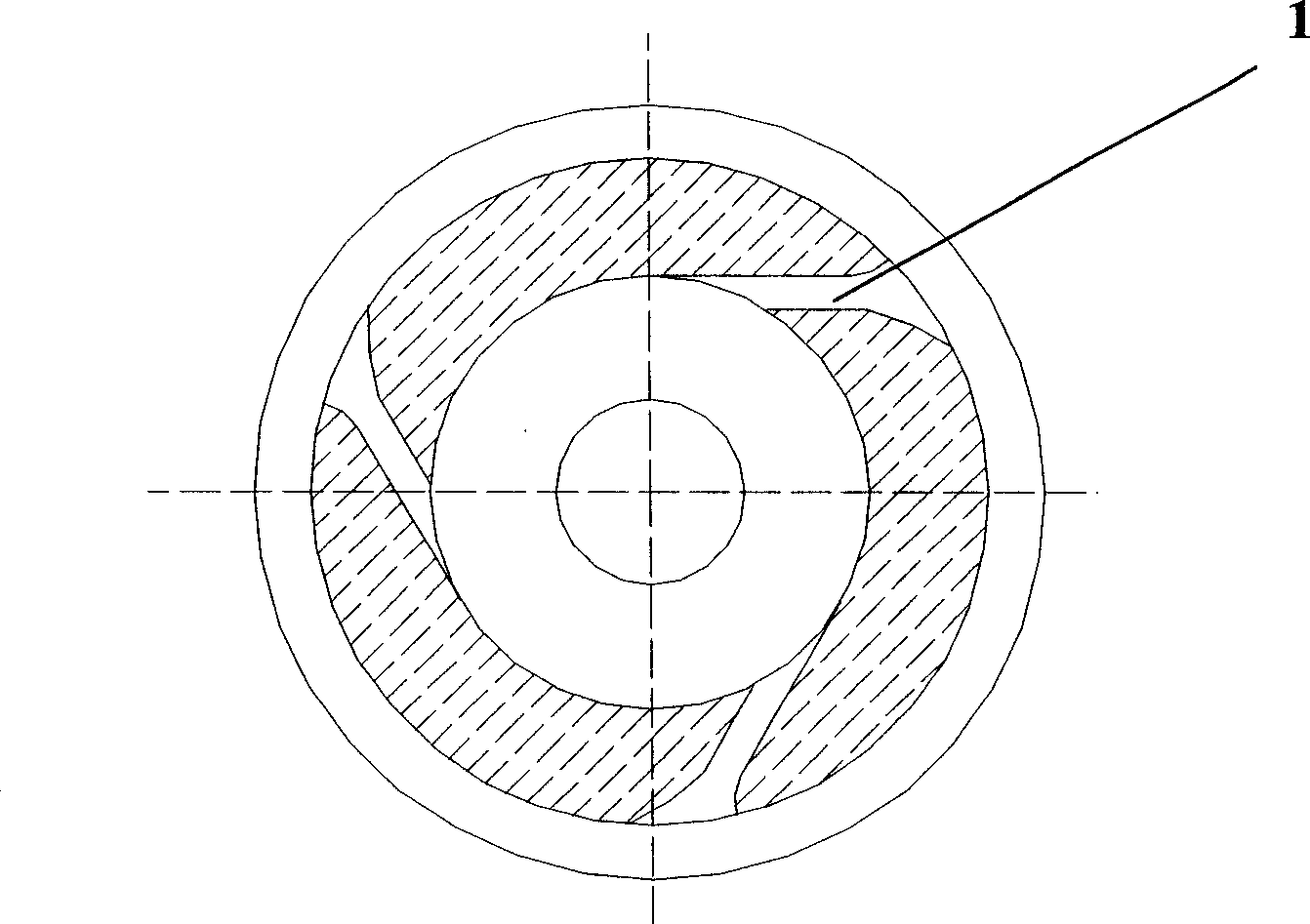

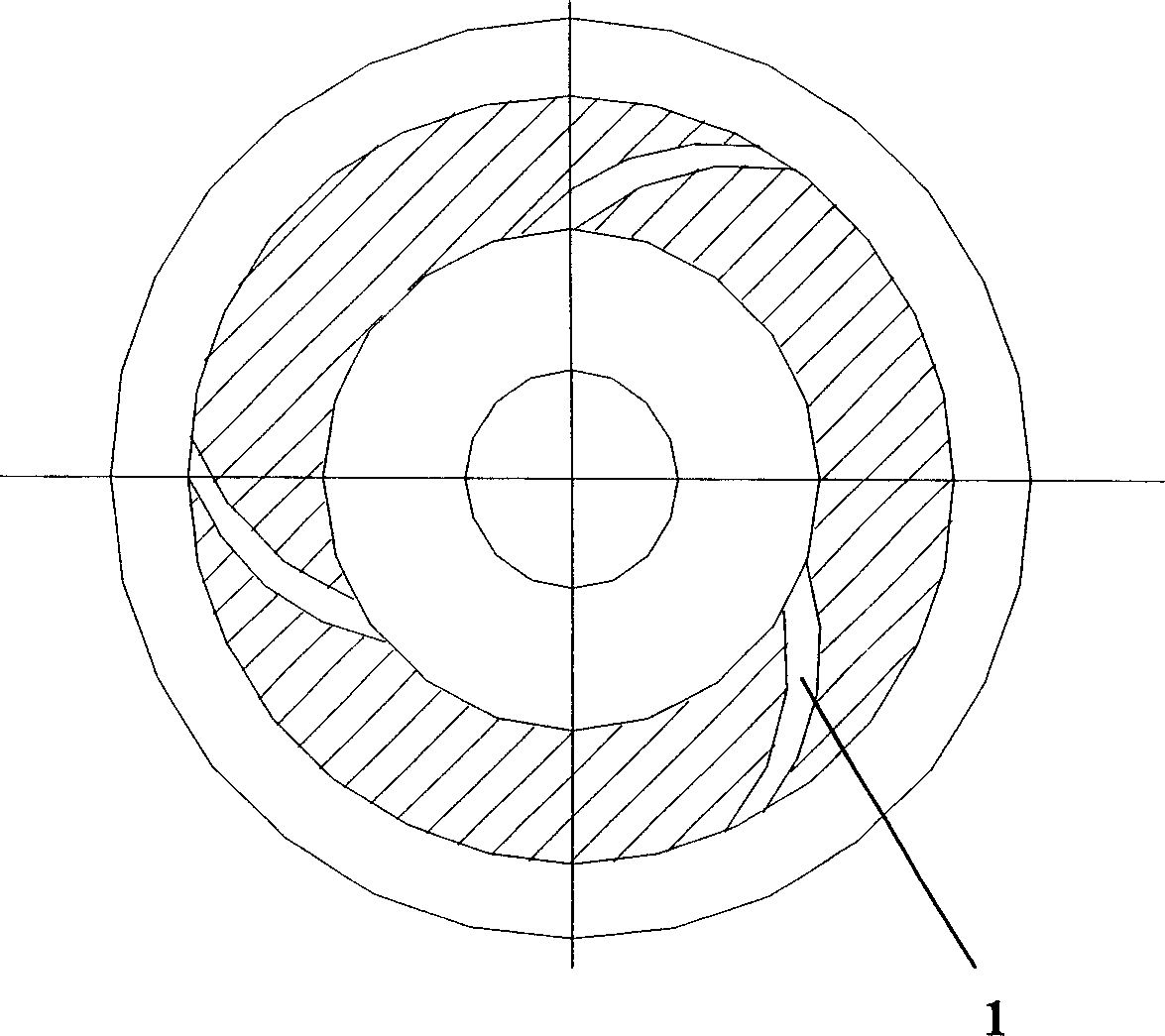

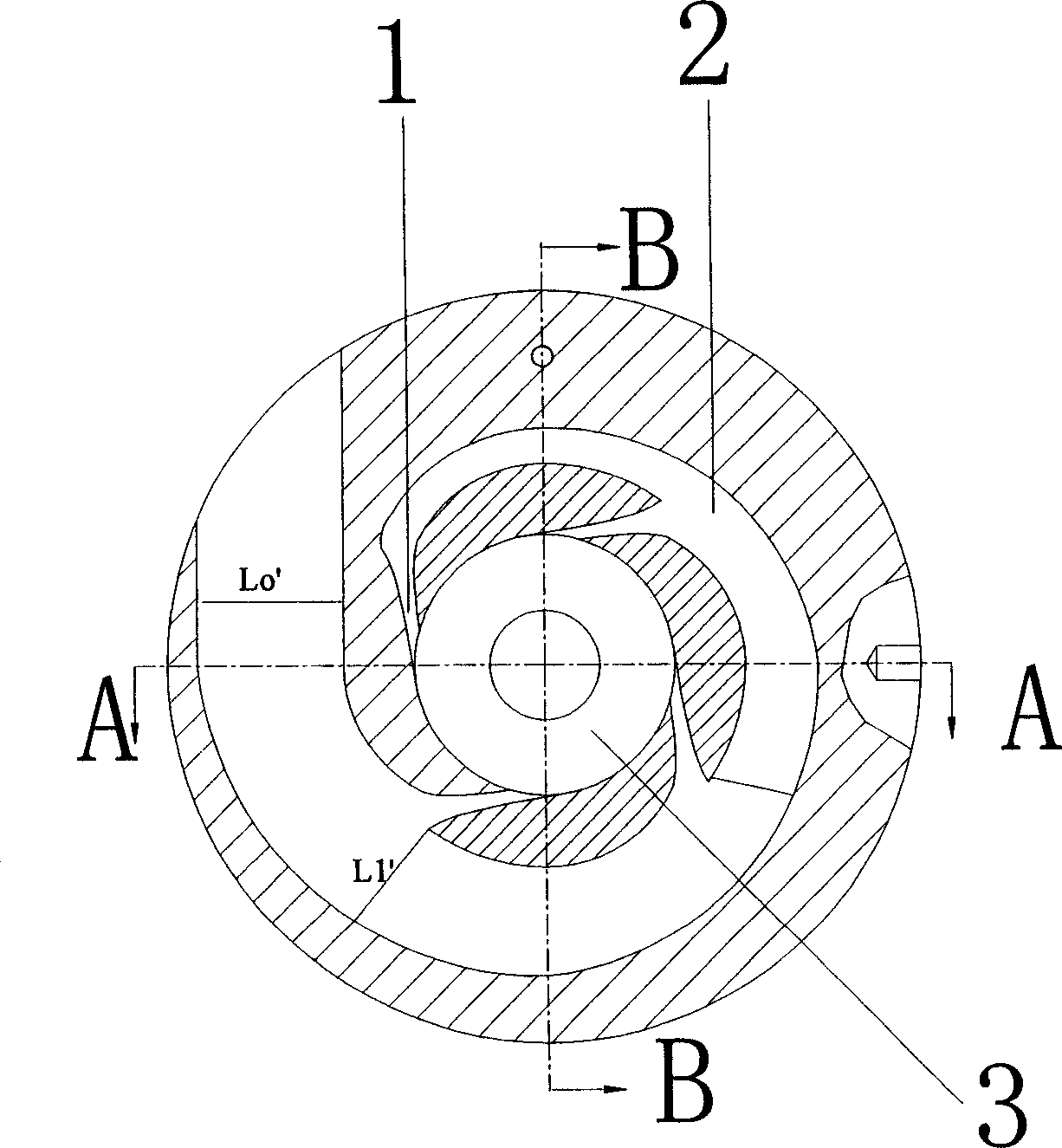

[0054] At the same time, change the shape of the nozzle flow channel 1 and the shape of the flow channel before the nozzle intake. For details, see the attached image 3 , 4 , 5, the number of nozzle runners is 3, and the slot width at the inlet of runner 2 before air intake is L 0 ' is 7.2mm, and the nozzle 6 and the cold end pipe 4 are connected by threads. The assembly of the nozzle and other parts of the vortex tube is as attached Figure 10 shown. Other dimensions of the nozzle: the same as in Embodiment 1.

[0055] Effect:

[0056] When the inlet pressure is 0.4MPa (absolute pressure), the inlet temperature is 24°C, the length of the hot end pipe is 140mm, and the number of nozzle flow channels is 3. The nozzle vortex tube of the present invention has a cold flow rate of 56.2%, reaching the lowest cold end temperature of -5.5°C; and under the same test conditions, using a common rectangular nozzle, the vortex tube reaches the lowest cold end temperature when the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com