Energy saving type CO2 double-machine double-level refrigeration multi-split air conditioner system

A multi-connected system, two-stage refrigeration technology, applied in refrigerators, gas cycle refrigerators, refrigeration components, etc., can solve the problems of inability to meet medium and low temperature ring cooling, low refrigeration capacity, etc., to improve the overall energy efficiency ratio, better Energy-saving advantages and the effect of broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

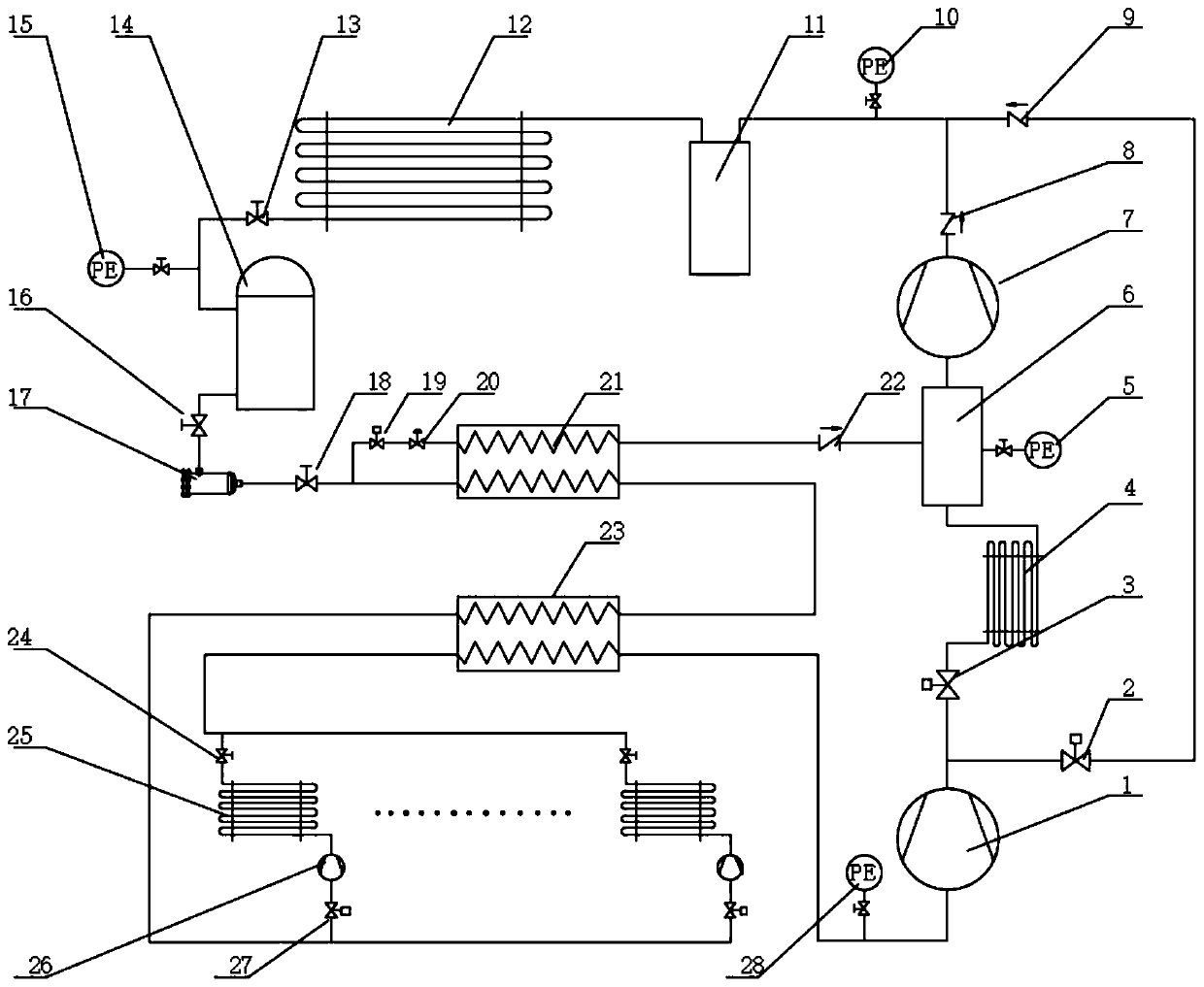

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Such as figure 1 As shown, an energy-saving CO 2 Two-machine two-stage refrigeration multi-line system, including subcritical compressor 1, mixing barrel 6, transcritical compressor 7, gas storage tank 14, intercooler 21 and regenerator 23, the output pipeline connection of subcritical compressor 1 There is a first gas cooler 4, the first gas cooler 4 is connected to the bottom of the mixing tank 6, the first pressure sensor 5 is installed on the inlet pipe of the mixing tank 6, the top of the mixing tank 6 is connected to the input of the transcritical compressor 7 The output end of the transcritical compressor 7 is connected with an oil separator 11 . During implementation, the output end of the subcritical compressor 1 is connected to the first gas cooler 4 through one branch of the three-way pipe, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com