Air suction silencer with conical air suction pipeline structure

A suction pipeline and muffler technology, applied in the field of compressors, can solve the problems that cannot be optimized and improved at the same time, so as to improve the energy efficiency ratio and noise effect of the whole machine, improve the cooling efficiency, increase the cooling capacity and the energy efficiency of the whole machine than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

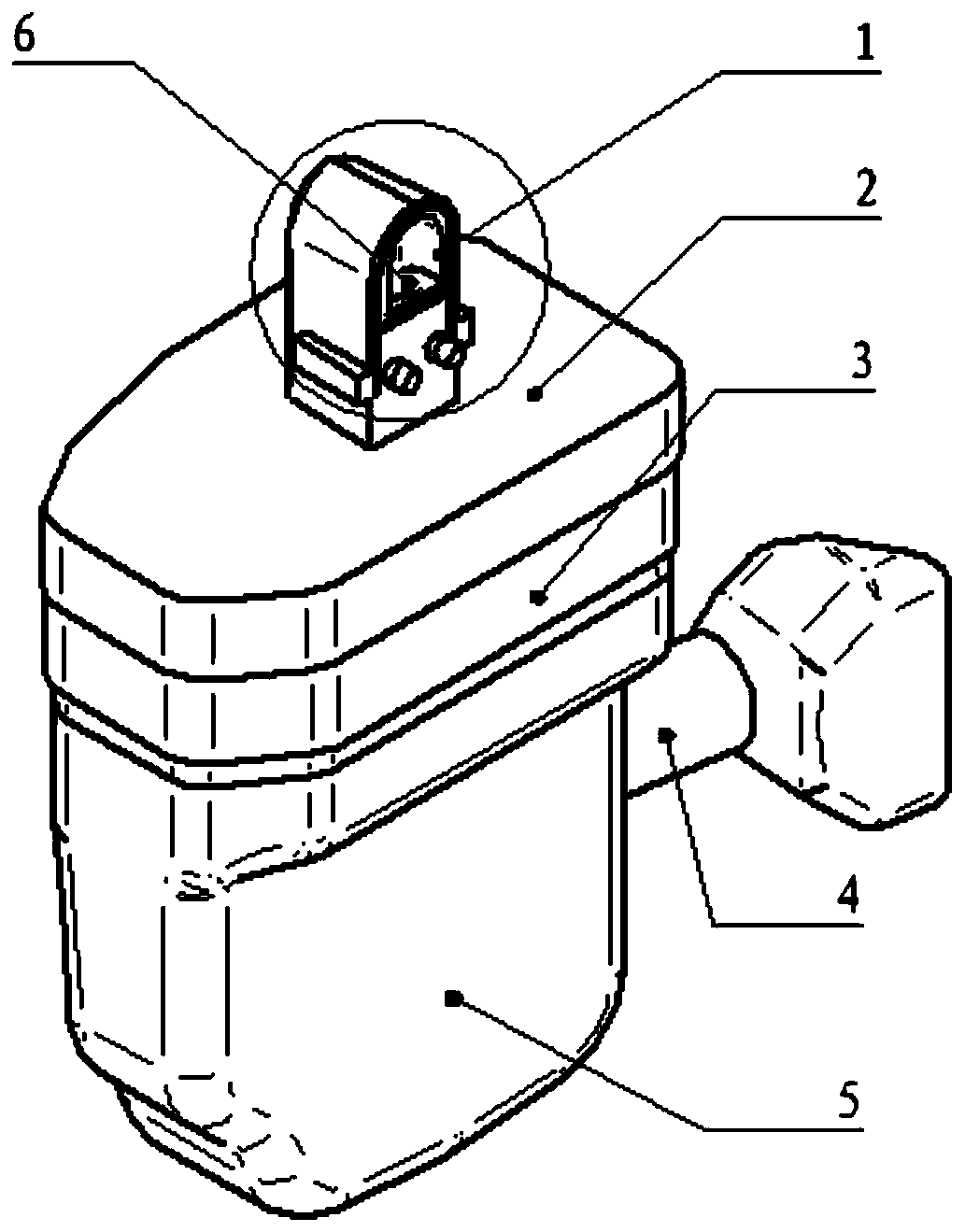

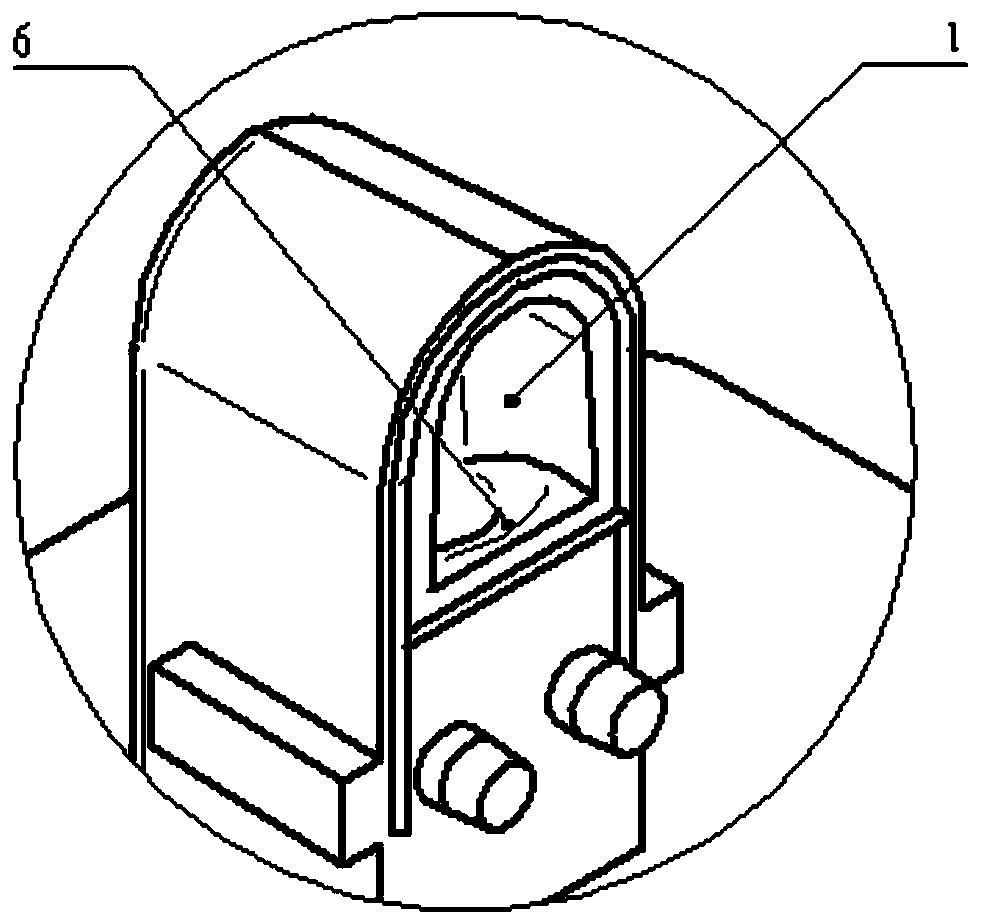

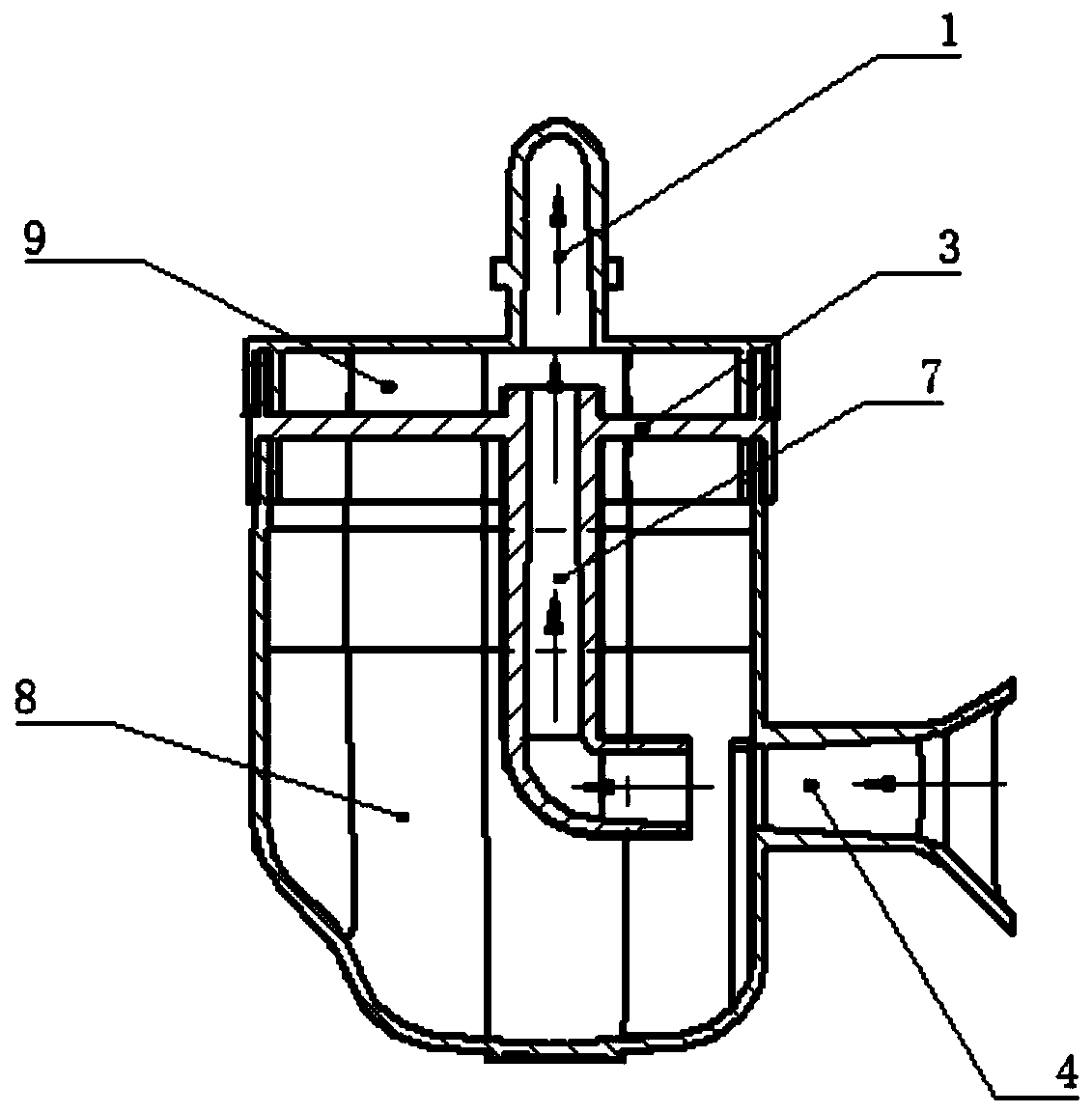

[0023] Such as figure 1 with Figure 5 As shown, the suction muffler with tapered suction pipeline structure of the present invention includes a muffler box 5, a partition 3 and a muffler cover 2, and the installation method of the partition 3 can be horizontal or vertical (this embodiment adopts horizontal placement), thereby forming upper muffler chamber 9 and lower muffler chamber 8 (please also refer to image 3 with Figure 4 ).

[0024] Such as figure 2 , image 3 with Figure 4 As shown, the muffler cover 2 is provided with an air outlet pipeline 1, the muffler box 5 is provided with an air intake pipeline 4, the partition 3 is provided with an inset pipeline 7, the air intake pipeline 4, the inset pipeline 7 and The cross-sectional shape of the inlet and outlet of the air outlet pipeline 1 is circular or elliptical, and the shape of the insertion pipeline 7 is a straight pipe (also can use a bent pipe, and the shape of the bent pipe can be L-shaped, U-shaped or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com