Method for reducing pressure of transformation system by extracting air

A technology for changing the system and pressure, which is applied in the field of reducing the pressure of the changing system by air extraction, which can solve the problems such as the limitation of the production capacity of the changing catalyst and the inability to increase the use pressure of the changing position, and achieve the effect of improving the gas transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

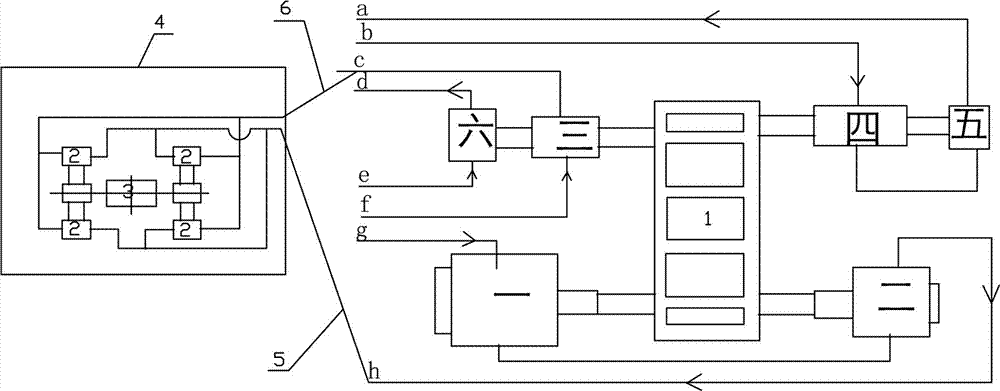

[0011] Example: As shown in the figure, during the first to sixth stage of compression in the synthetic ammonia production process, the incoming gas from the gas tank g enters the first stage of compression, passes through the second stage of compression to the transformation and depletion h, and the depleted incoming gas f enters the third stage of compression. , From the third stage compression to decarburization c, the decarburization incoming gas b enters the fourth stage compression, from the fifth stage compressed gas to the refining a, the refined incoming gas e enters the sixth stage compression, from the sixth stage compression to the synthesis d, When the present invention is implemented, in the conversion station of the synthetic ammonia production process, the outlet header 5 of the conversion is used to pump air by the compressor 4 to reduce the outlet pressure of the conversion system, thereby reducing the pressure of the conversion system.

[0012] The compressor 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com