Low wind resistance type thin evaporator and indoor unit of air conditioner

An evaporator and wind resistance technology, which is applied in the field of low wind resistance and high efficiency heat exchange thin evaporators, can solve the problems of unfavorable miniaturization, heat exchange efficiency, and energy efficiency ratio reduction cost is difficult to balance, and achieves compact structure, reasonable and effective wind field distribution, The effect of reducing the overall wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

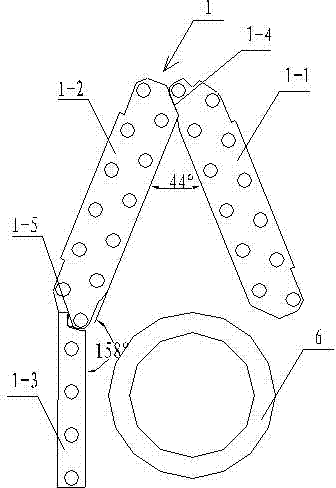

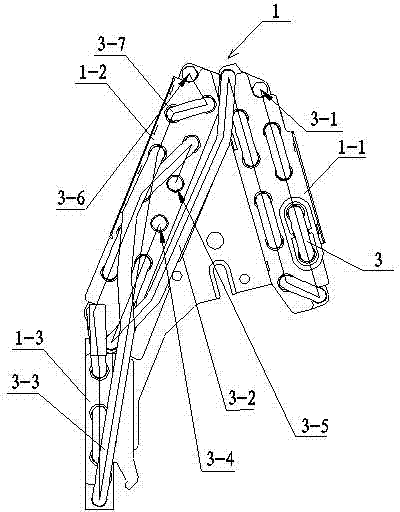

[0033] see figure 1 , the present invention is a thin evaporator 1 with low wind resistance. The evaporator B1-2 is a double-row structure, the evaporator C1-3 is a single-row structure, the evaporator A1-1 is connected to the evaporator B1-2, and the evaporator C1-3 is connected to the evaporator B1-2. The evaporator B1-2 is connected, and the evaporator C1-3 is located at the lower part of the evaporator B1-2. In order to avoid gaps between the joint surfaces of the two-stage evaporators and prevent water blowing, the joint surface between the evaporator A1-1 and the evaporator B1-2 is a slope 1-4, and the contact length of the slope 1-4 is 12- Between 18mm, the positions of the two slopes 1-4 are close to the inside of the upper part of the evaporator A1-1 and the evaporator B1-2. Due to the large contact area of the two slopes 1-4, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com