High-efficiency air-condition heat exchanger fin and heat exchanger

A heat exchanger and fin technology, applied in the field of high-efficiency heat exchanger fins, can solve the problems of low heat exchange efficiency, achieve the effects of small wind resistance, increase the contact area, and improve the energy efficiency ratio of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

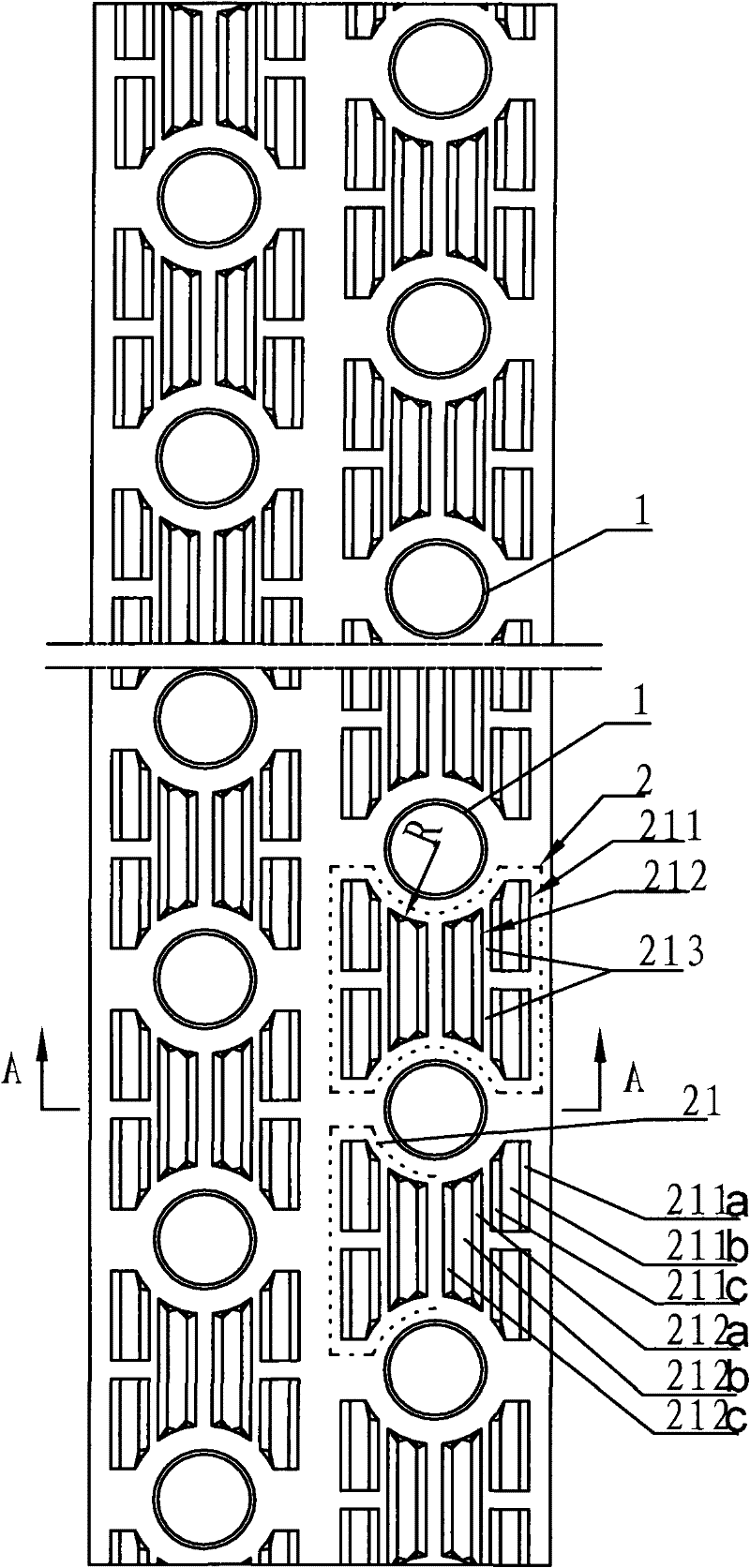

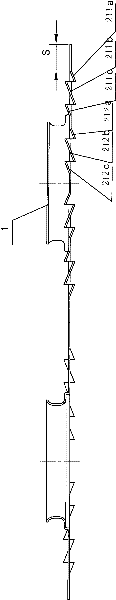

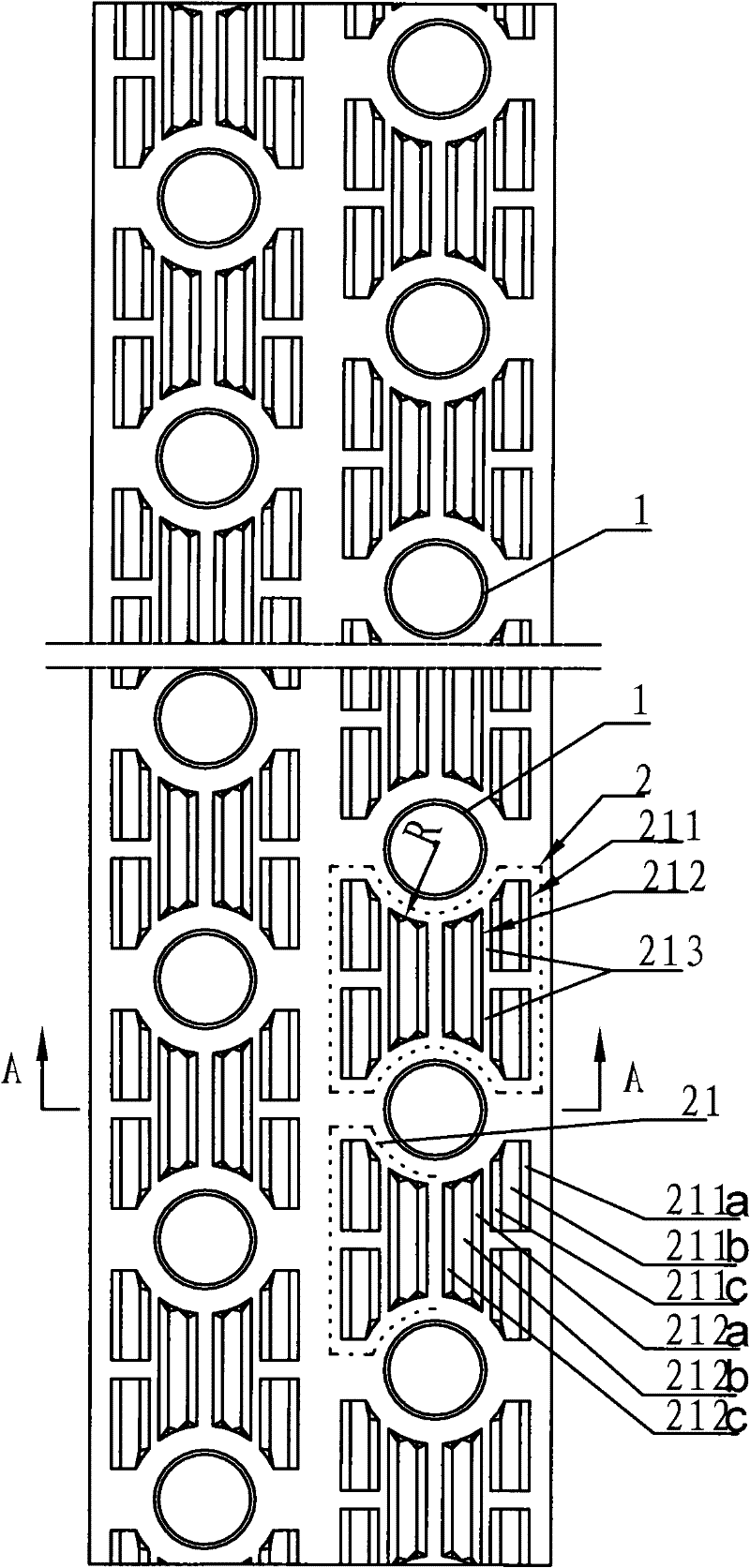

[0022] see figure 1 and figure 2 , in order to propose a new type of windowed fin with greatly improved heat transfer capacity and small resistance increase, in order to obtain higher heat transfer efficiency. A specific embodiment of the present invention is that the fins have two rows, and each row of fins has several copper tube holes 1, and the upper and lower sides of each copper tube hole 1 are symmetrically provided with the same window unit 2, each of which The window unit 2 is arranged left and right symmetrically by the same window group 21 , and each window group 21 is composed of the same short window group 211 and the middle long window group 212 arranged at intervals up and down on the outer side. The short window set 211 and the long window set 212 have a plurality of windows, and each window is inclined at the same angle. The incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com