CO2 refrigeration piston compressor with turbine expansion mechanism

A technology of turbo expansion and compressor, which is applied in the direction of machines/engines, piston pumps, mechanical equipment, etc., can solve the problems of low energy efficiency and difficulty in popularization, so as to improve operating energy efficiency, increase unit cooling capacity, and reduce motors The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

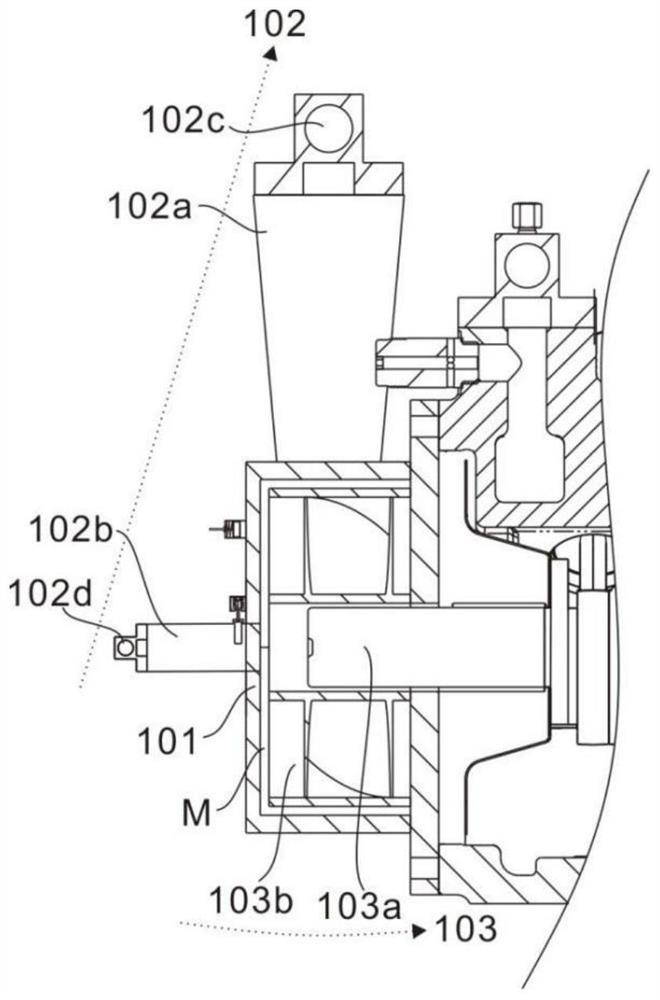

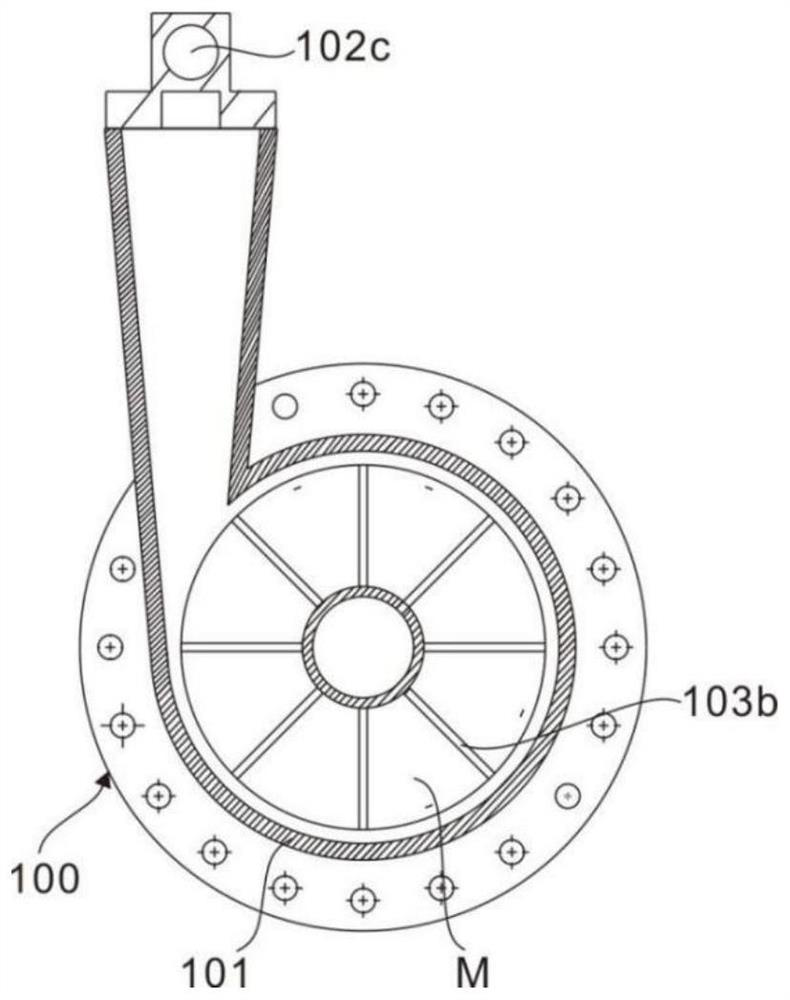

[0033] refer to figure 1 and figure 2 , is the first embodiment of the present invention, which provides a CO with a turbo expansion mechanism 2 Refrigeration piston compressor, CO with turbo expansion mechanism 2 The refrigeration piston compressor includes an expansion unit 100 , and the expansion unit 100 includes an expansion shell 101 , a gas channel 102 and a working assembly 103 .

[0034] Specifically, an accommodating space M is provided inside the expansion shell 101, and the normal temperature and high pressure CO 2 After the gas enters the expansion shell 101, because the gas enters a relatively low-pressure (such as normal temperature) space from a high-pressure state, it can expand in the accommodation space M, thereby acting externally, wherein the normal temperature and high pressure CO 2 The pressure range of the gas is 7MPa-13MPa, and the temperature range is 15°C-40°C.

[0035] The gas passage 102 of the expansion unit 100 includes an intake passage 102...

Embodiment 2

[0039] refer to image 3 and Figure 4 , is the second embodiment of the present invention, in this embodiment,

[0040] The gas channel 102 of the expansion unit 100 also includes a first suction valve 102c and a first exhaust valve 102d. The first suction valve 102c is arranged at one end of the gas intake channel 102a for controlling the external CO 2 For the input of gas, the first exhaust valve 102d is set at one end of the exhaust channel 102b to control the discharge of CO 2 The expanded CO in the accommodation space M 2 gas.

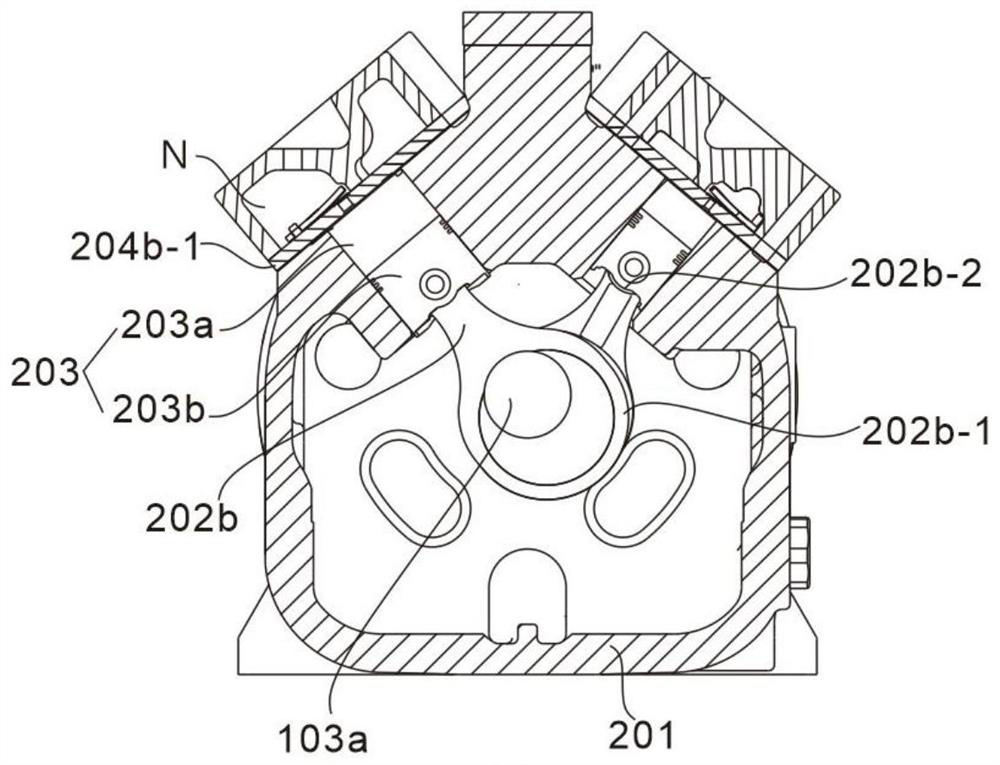

[0041] The expansion unit 100 is connected with the compression unit 200 , and the compression unit 200 includes a compression housing 201 and a power assembly 202 . Wherein, one side of the compression housing 201 is provided with a partition 201a, and the partition 201a is arranged on the side adjacent to the expansion housing 101, the compression housing 201 is used to seal the compression unit 200, and the partition 201a connects the expa...

Embodiment 3

[0045] refer to Figure 1~4 , is the third embodiment of the present invention, in this embodiment,

[0046] Specifically, the compression unit 200 also includes a compression assembly 203, which includes a cylinder 203a and a piston 203b. The cylinder 203a is disposed inside the compression housing 201, and the piston 203b is movably connected to the second ring 202b-2 at one end of the connecting rod 202b. Into the cylinder 203a, the diameter of the first ring 202b-1 is larger than the diameter of the second ring 202b-2, when the transmission part 103a rotates, it drives the connecting rod 202b to move, and the rotary motion of the transmission part 103a is converted into the reciprocating motion of the piston 203b through the connecting rod 202b movement, so that the low-temperature and low-pressure CO in the cylinder 203a 2 The gas is compressed into high temperature and high pressure CO 2 gas.

[0047] Wherein, compression housing 201 also comprises motor cover 201b an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com