Ejector enhanced quasi-two-stage compression type circulating system

A circulation system and injector technology, applied in the field of quasi-two-stage compression circulation system, can solve problems such as the decrease of the effective use area of the heat exchanger, the increase of irreversible loss, and the increase of the size of the heat exchanger, so as to ensure energy saving and Stability, improving utilization, and reducing the effect of suction specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

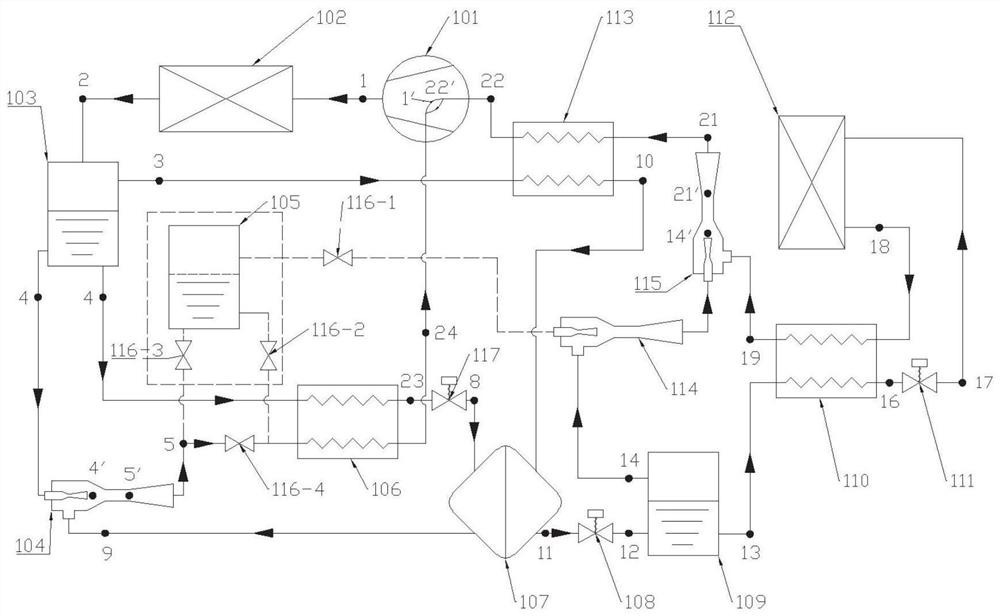

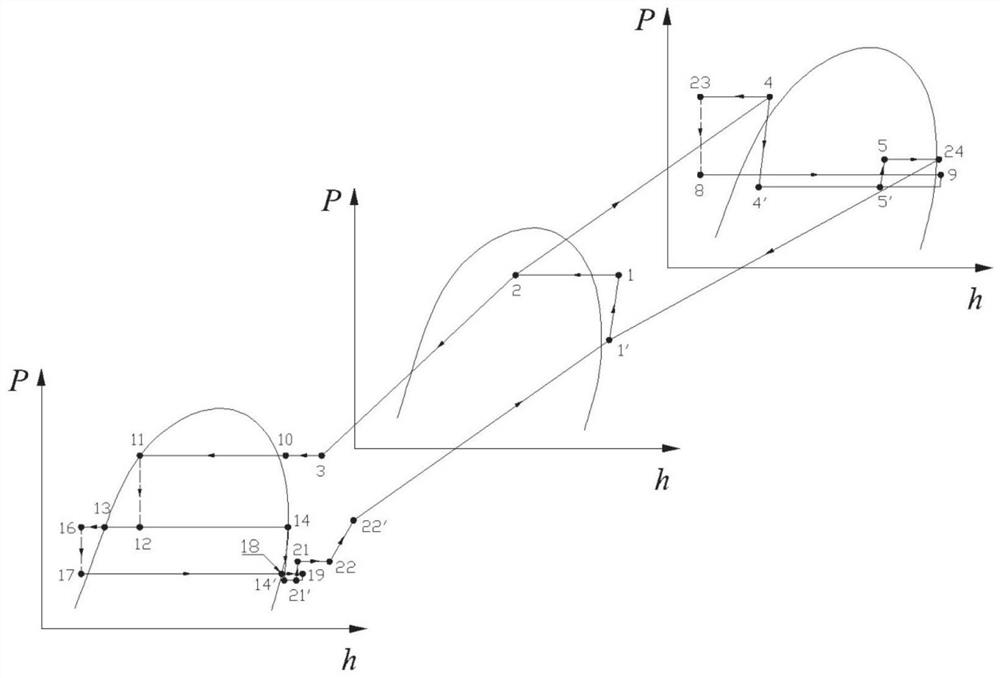

[0044] This embodiment provides a quasi-two-stage compression cycle system with ejector boost, which is a self-cascading quasi-two-stage compression refrigeration cycle system with ejector boost, such as figure 1 As shown, it includes a compressor 101, a condenser 102, an evaporator 112, an evaporative condenser 107, three gas-liquid separators, three ejectors and three regenerators.

[0045] In this embodiment, the existing equipment can be used for the regenerator, which has a superheated side and a supercooled side. The working fluid to be heated flows in from the inlet of the superheated side and flows out from the outlet of the superheated side, and the working fluid to be cooled is imported from the supercooled side. Inflow, outflow from the supercooled side outlet.

[0046] The superheated side of the regenerator means that the working fluid flows into the regenerator from the inlet of the superheated side, and flows out of the regenerator at the outlet of the superheat...

Embodiment 2

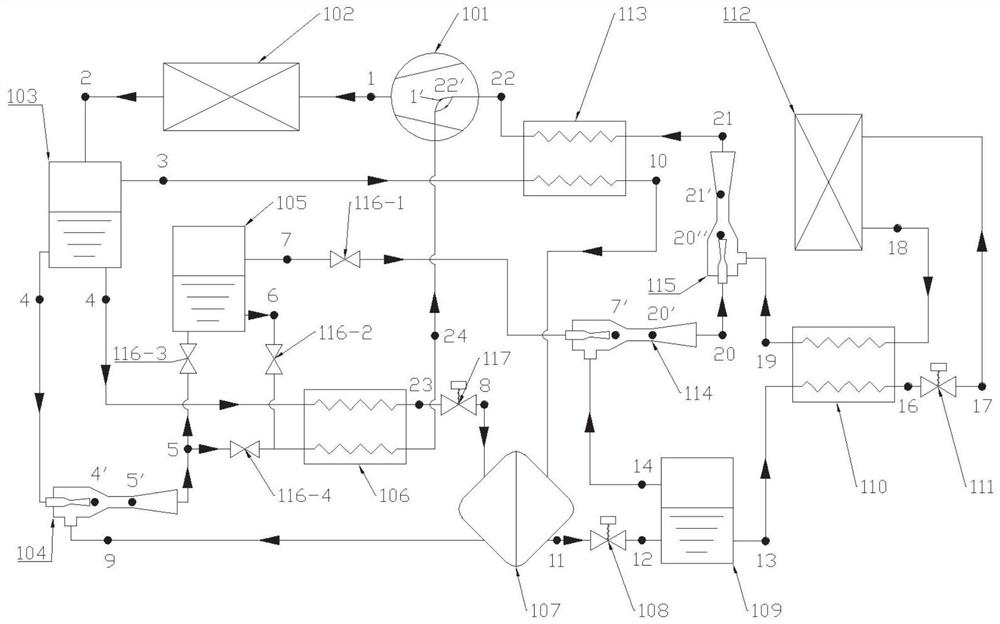

[0078] This embodiment provides a quasi-two-stage compression circulation system with ejector enhancement, which is a quasi-two-stage compression heat pump circulation system with ejector enhancement.

[0079] Such as Figure 5-Figure 6 As shown, it includes a compressor 101, the outlet of the compressor 101 is connected to the inlet of the condenser 102 through a pipeline, and the outlet of the condenser 102 is divided into two paths, one of which passes through the pipeline and the primary flow of the fourth ejector 118 The inlet is connected, and the other is connected to the inlet of the fourth pressure-reducing and cooling element through a pipeline. In this embodiment, the fourth pressure-reducing and cooling element adopts the fourth throttle valve 119 .

[0080] The outlet of the fourth ejector 118 is connected to the superheated side inlet of the fifth regenerator 120, the superheated side outlet of the fifth regenerator 120 is connected to the inlet of the fourth gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com