Vertical liquid reservoir and refrigerating system with liquid reservoir

A liquid accumulator, vertical technology, applied in the field of vertical accumulators and refrigeration systems with the accumulator, can solve the problems of uneven internal pressure, large liquid exchange resistance, etc., so as to prolong the service life and reduce the occupation. time, the effect of improving dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

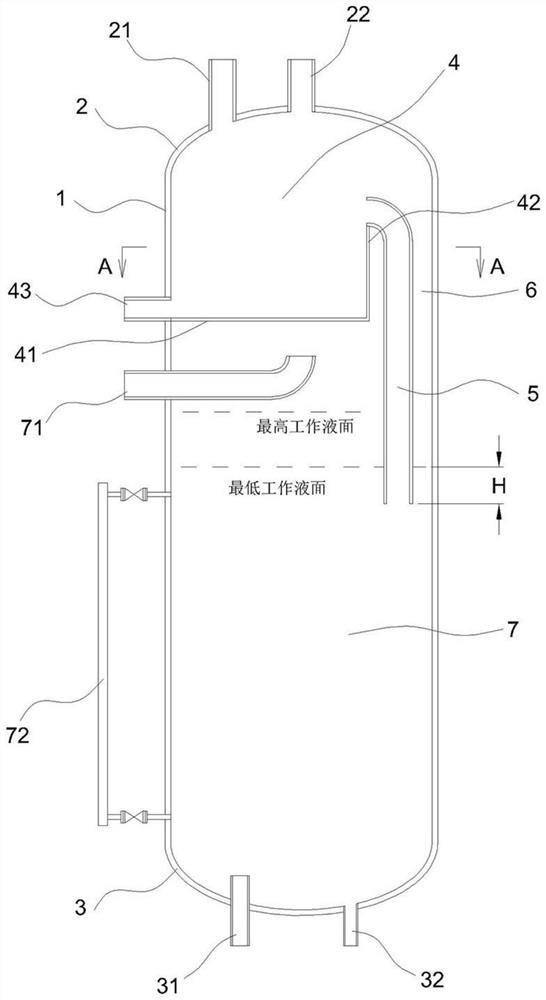

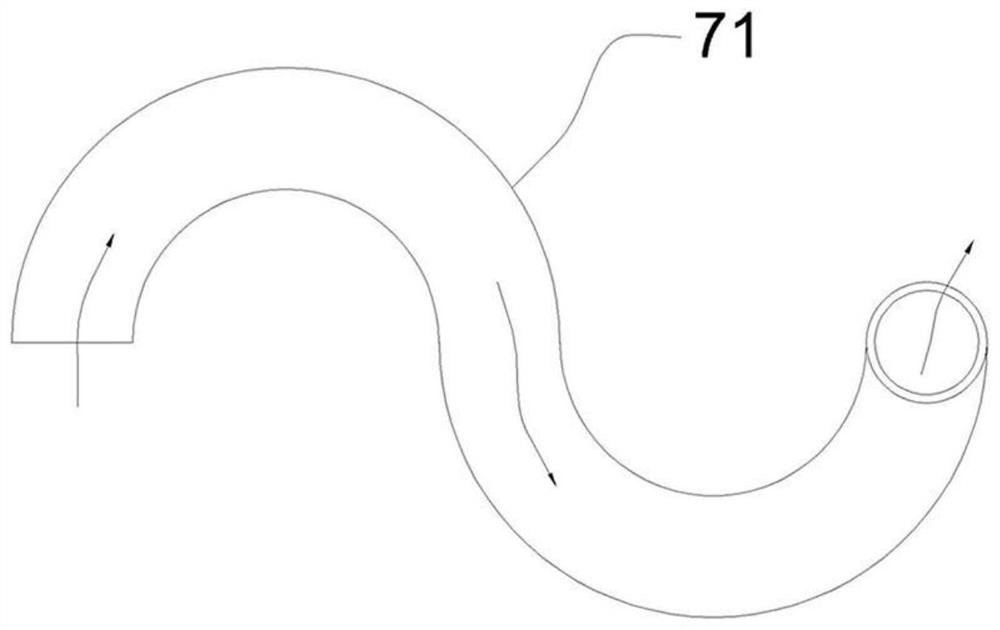

[0047] Such as figure 1As shown, this embodiment provides a vertical liquid reservoir that can overflow smoothly, including a cavity composed of a cylinder body 1, an upper seal body 2 and a lower seal body 3, and a partition device is provided in the cavity to separate the cavity It is divided into a buffer chamber 4 at the upper part and a liquid storage chamber 7 at the lower part, wherein a downcomer 5 and a gas flow channel 6 are arranged between the buffer chamber 4 and the liquid storage chamber 7, and the lower end of the downcomer 5 extends into the liquid storage chamber Below the minimum working liquid level of 7, prevent gas from entering from downcomer 5 lower ends.

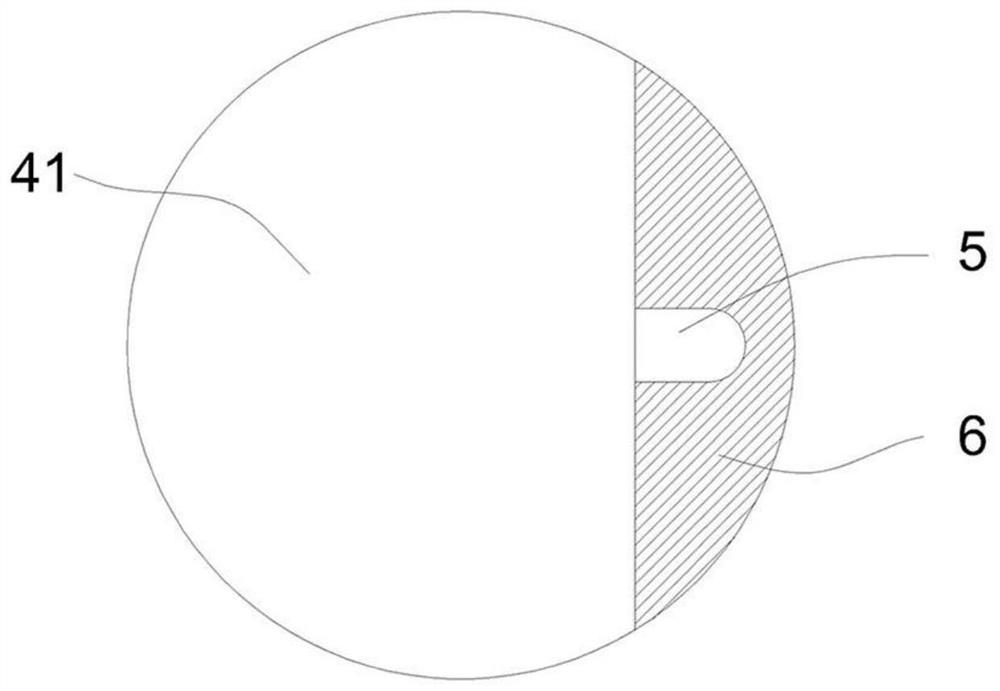

[0048] The specific structure of the partition device is as follows, which includes a horizontal partition 41 and a vertical partition 42, wherein the horizontal partition 41 is located at the bottom of the buffer chamber 4 and part of the sides are fixed on the cylinder 1. The simpler way is to plac...

Embodiment 2

[0061] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that this solution adds a heat exchange tube 74 and an oil separator 8 under the liquid surface of the liquid storage chamber 7 .

[0062] When the heat exchange tube 74 is installed separately, it can transfer the cold energy to the refrigerant liquid in the liquid storage chamber 7 by passing the low-temperature and low-pressure refrigerant gas into the heat exchange tube 74, and the refrigerant gas in the heat exchange tube 74 It can be saturated or overheated after heating up, and it can avoid liquid shock when it is sucked by the compressor.

[0063] In order to realize the separation of oil and gas in the liquid receiver, in this embodiment, the oil separator 8 is placed in the refrigerant liquid (below the lowest working liquid level), so that the heat exchange tube 74 can also transfer the cooling capacity to the oil separator 8, At the same time, the oil separator 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com