A subway train air conditioning unit with an exhaust air subcooler

A technology for air conditioning units and subcoolers, which is applied to subcoolers, refrigerators, refrigeration components, etc., can solve the problems of poor heat exchange effect of heat exchangers, low refrigeration efficiency of units, and size limitations, and achieve enhanced heat exchange effects. , Improve operational reliability and refrigeration efficiency, reduce the effect of condensing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

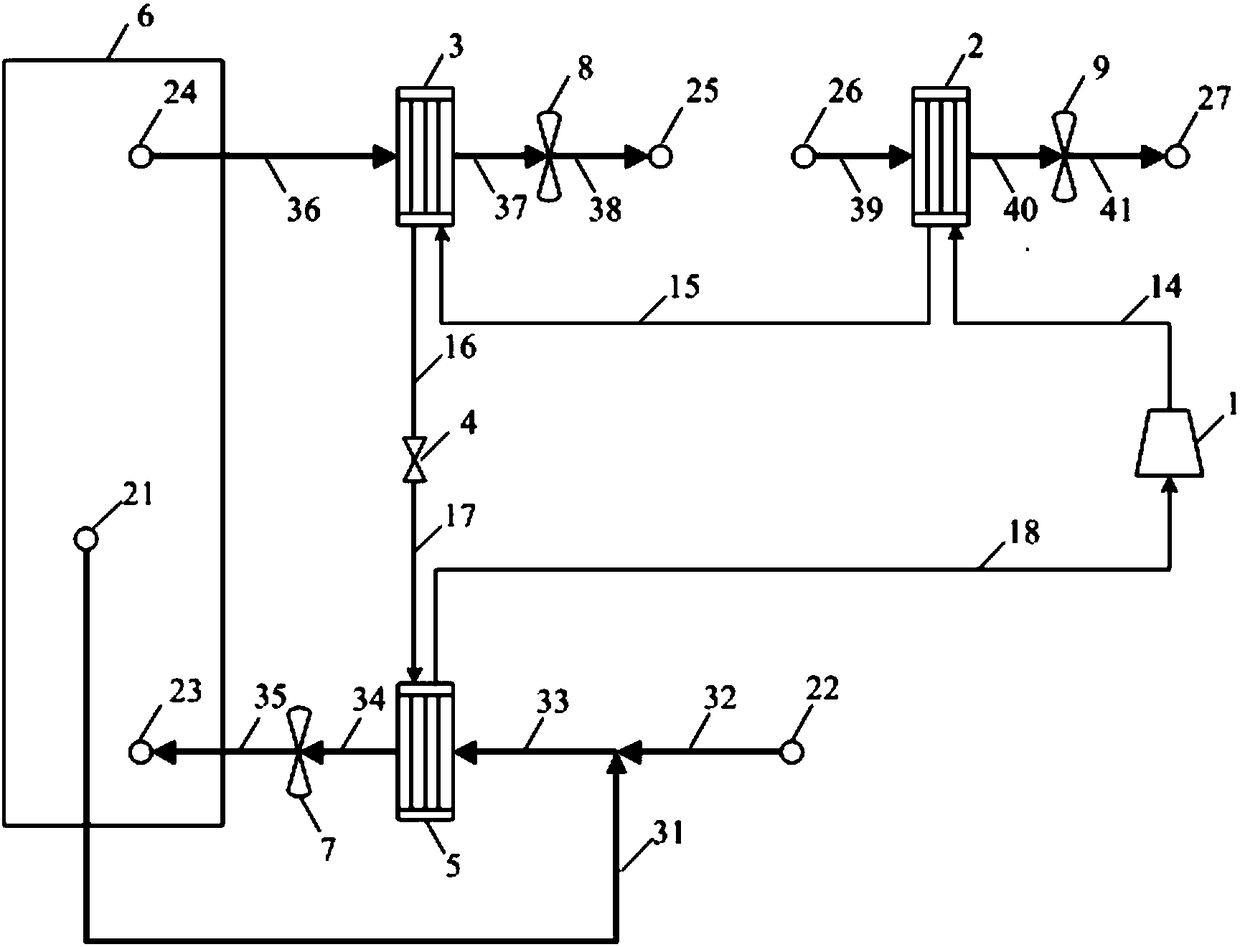

[0023] A subway train air conditioning unit with an exhaust air subcooler, its structure and flow are as follows figure 1 As shown, the air conditioning unit includes a refrigerant circuit and an air circuit.

[0024] The refrigerant circuit includes a compressor 1, a condenser 2, a subcooler 3, a throttling device 4, and an evaporator 5 that are sequentially connected in circulation, wherein the condenser 2, the subcooler 3, and the evaporator 5 all include refrigerant passages and Air channel, in the refrigerant circuit, the condenser 2, the subcooler 3 and the evaporator 5 are all connected to the refrigerant channel, and the specific process is as follows: the low-temperature and low-pressure refrigerant vapor coming out of the evaporator 5 refrigerant channel is refrigerated The refrigerant connecting pipe 18 enters the compressor 1, and becomes a high-temperature and high-pressure refrigerant vapor under the action of the compressor 1; enters the refrigerant passage of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com