Efficient electric cold and warm air heat exchange system used for vehicle

A heat exchange system and technology for vehicles, which is applied in the field of high-efficiency vehicle electric cooling and heating air heat exchange systems, can solve the problems of insufficient heating and high exhaust temperature of compressors, increase the coefficient of performance of heating and cooling, and increase the heating capacity , the effect of increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

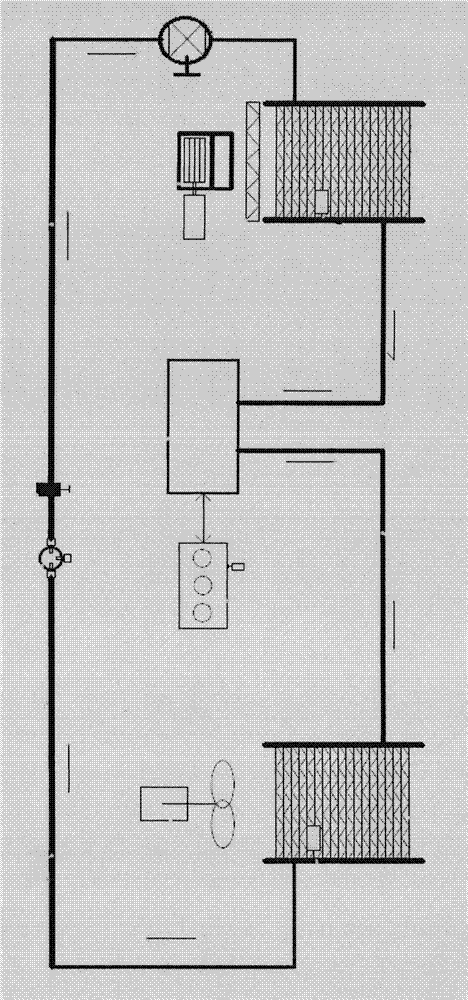

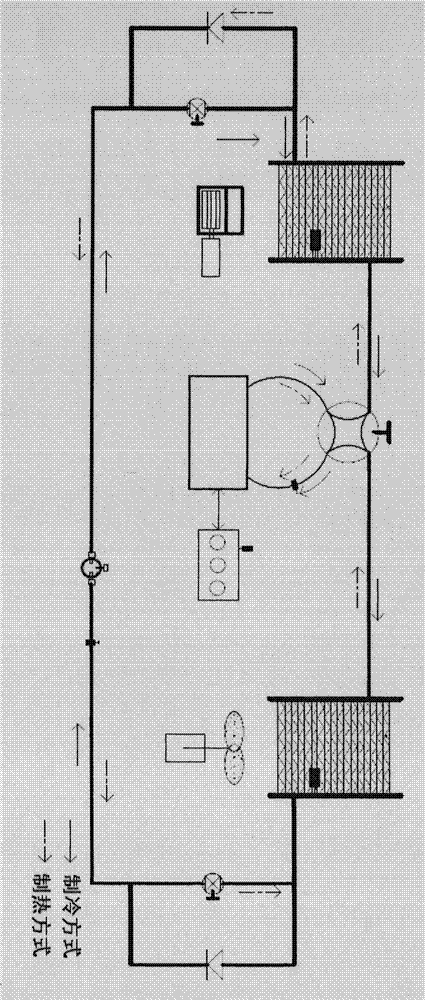

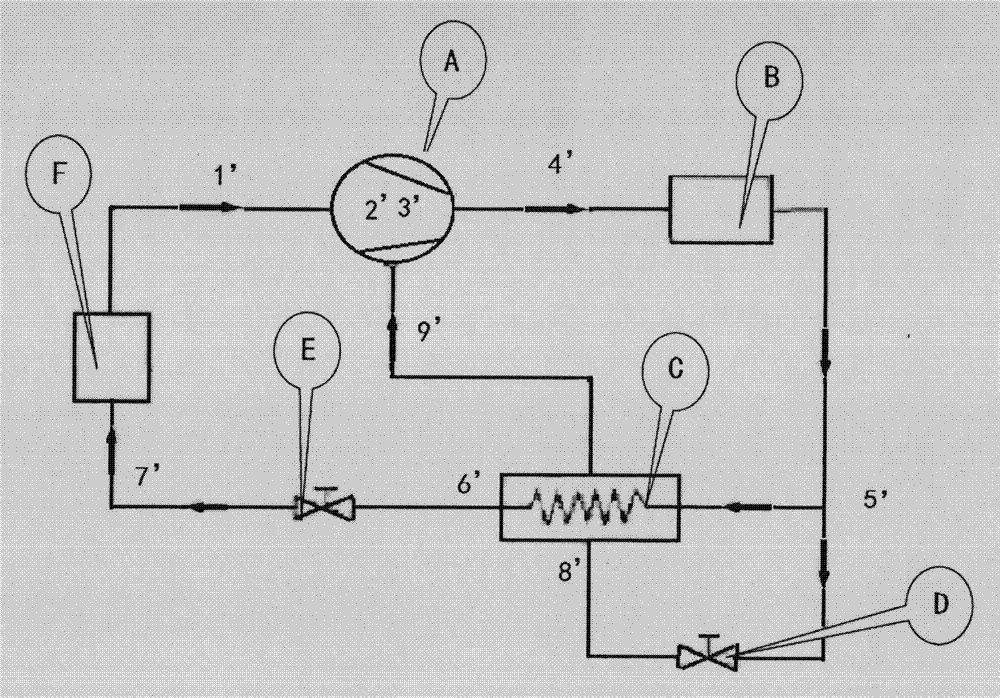

[0023] as attached Figure 5As shown, the high-efficiency vehicle electric cooling and heating air heat exchange system described in this embodiment includes a permanent magnet-reluctance vehicle integrated electric compressor 2 with an air supplement function, a four-way reversing valve 3, and a heat exchange system outside the vehicle. 4, in-vehicle heat exchanger 15, liquid storage tank 9 and economizer 20; the exhaust pipe 21 and suction pipe 22 of the integrated electric compressor 2 are connected to the four-way reversing valve, and the in-vehicle heat exchanger 15 One inlet and outlet end of the heat exchanger 4 outside the vehicle is respectively connected to the four-way reversing valve 2 through the external unit pipe 23 of the four-way reversing valve and the internal unit pipe 27 of the four-way reversing valve; The other inlet and outlet of the heat exchanger 4 pass through the electronic expansion valve assembly I7, the high-pressure pipe I24, and the liquid stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com