Jet type supercooling refrigeration system

A refrigeration system and jet technology, applied in subcoolers, refrigerators, refrigeration components, etc., can solve the problems of increasing input cost and operating cost, and achieve the effect of reducing input cost, sufficient cooling process, and large heat exchange temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

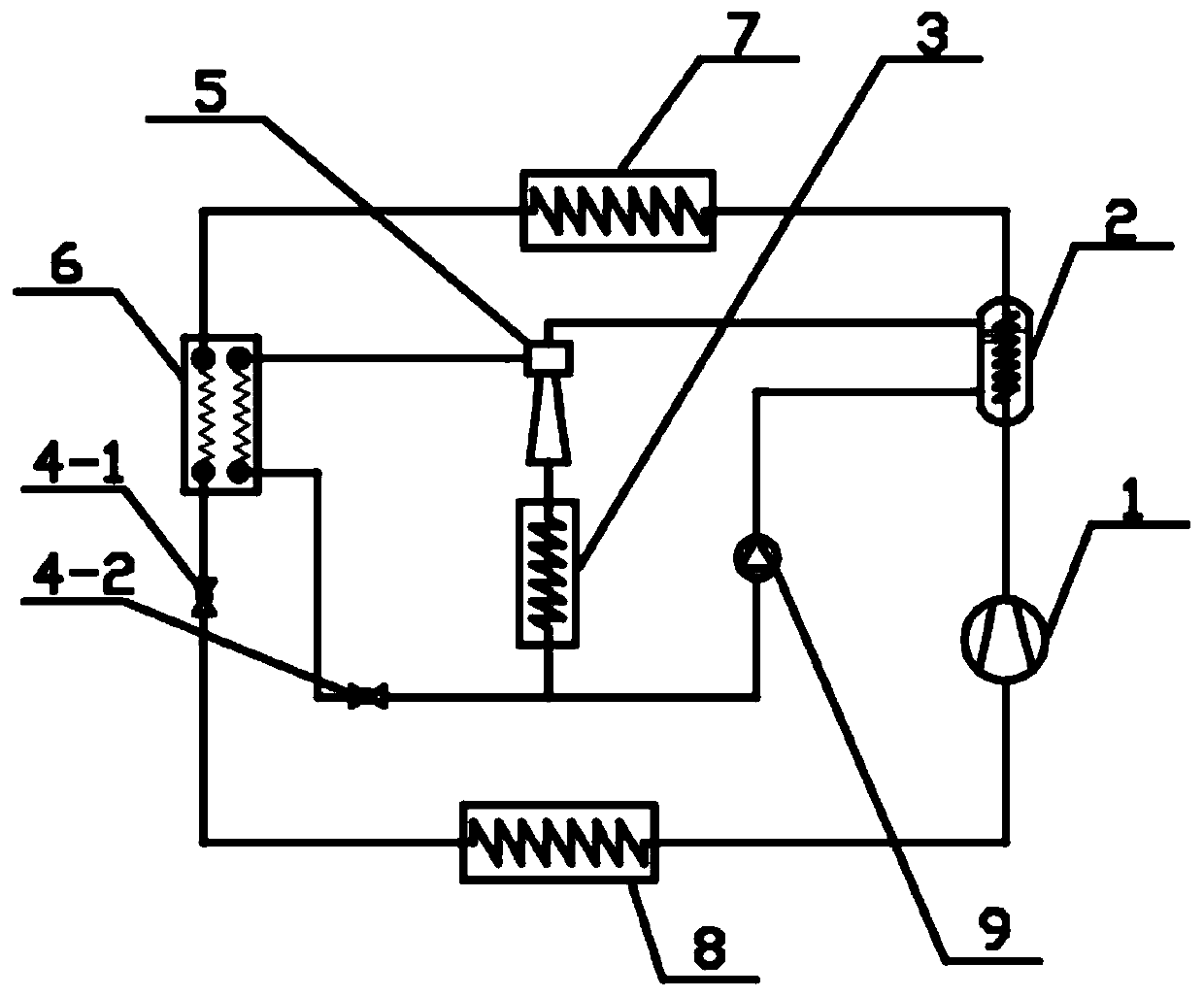

[0022] The schematic diagram of the injection type subcooling refrigeration system of the present invention is as follows: figure 1 As shown, it includes a main refrigeration cycle and an ejector subcooling refrigeration cycle. The main refrigeration cycle is composed of the compressor 1, the tube side channel of the generator 2, the main condenser 7, and the subcooling side channel of the subcooler 6. , the first throttling device 4 - 1 and the evaporator 8 are connected in sequence and then return to the closed cycle of the suction port of the compressor 1 . The ejector type subcooling refrigeration cycle includes the ejector 5, branch condenser 3, second throttling device 4-2 and circulation pump 9, the high-pressure fluid inlet of the ejector 5 is connected to the shell side of the generator 2 The outlet of the ejector 5 is connected to the inlet of the branch condenser 3, and the outlet of the branch condenser 3 is divided into two paths, one of which passes through the s...

Embodiment 2

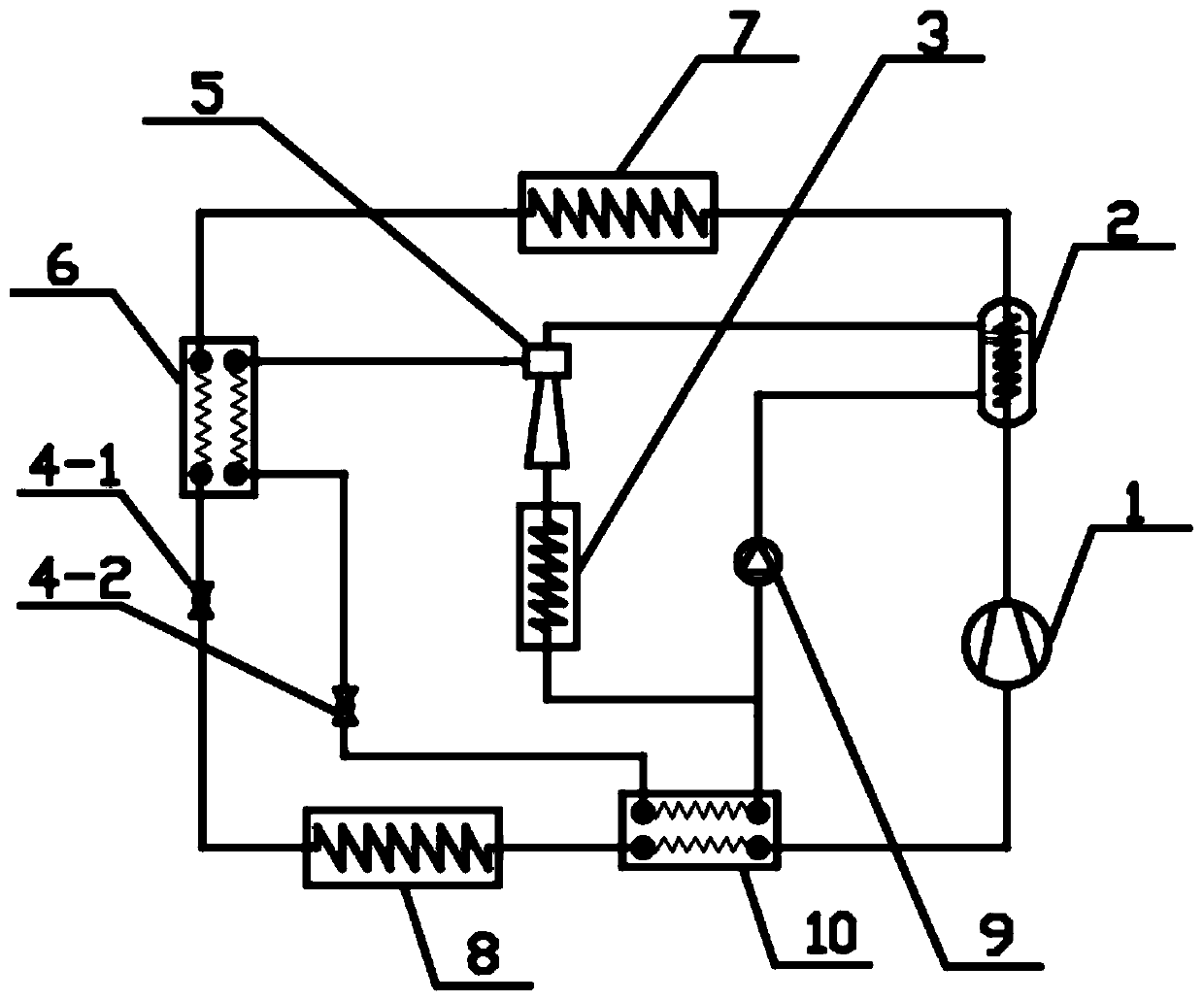

[0025] The schematic diagram of the injection type subcooling refrigeration system with superheater of the present invention is as figure 2 Shown, including the main refrigeration cycle and injection subcooling refrigeration cycle. The main refrigeration cycle is composed of the compressor 1, the tube side passage of the generator 2, the main condenser 7, the subcooling side passage of the subcooler 6, the first throttling device 4-1, the evaporator 8 and the superheating The inlet and outlet of the superheated side of the device 10 are connected in sequence and then return to the closed cycle of the suction port of the compressor 1. The ejector type subcooling refrigeration cycle includes the ejector 5, branch condenser 3, second throttling device 4-2 and circulation pump 9, the high-pressure fluid inlet of the ejector 5 and the shell of the generator 2 The side outlet is connected, the outlet of the ejector 5 is connected to the inlet of the branch condenser 3, the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com