Method for preparing liquid by low-temperature rectification

A low-temperature rectification and rectification technology, which is applied in refrigeration, liquefaction, liquefaction, solidification, etc., can solve the problems of high working pressure, difficult operation, and increased floor space of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

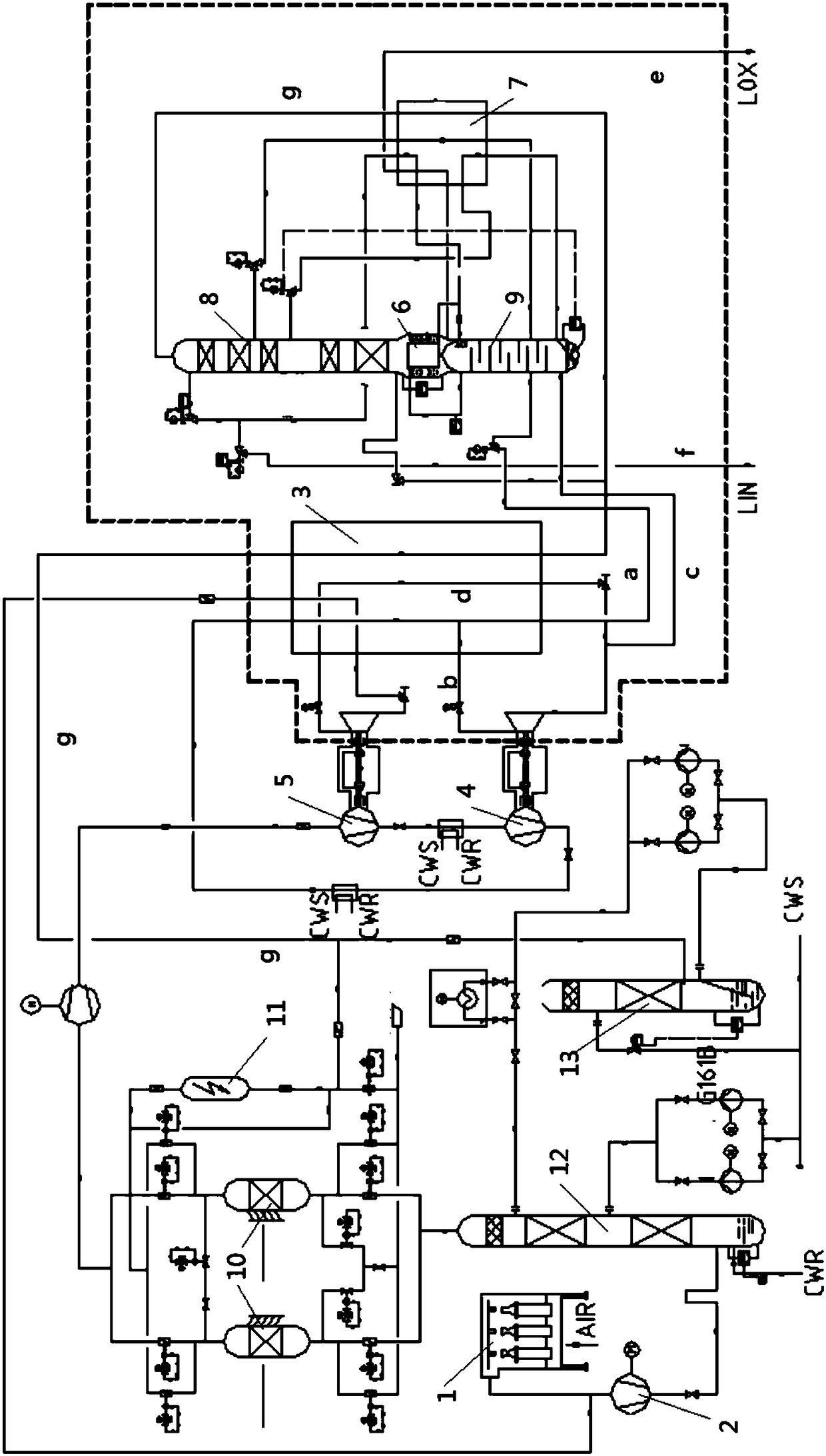

[0015] Such as figure 1 The shown device for obtaining liquid by low temperature rectification includes a filter 1, an air compressor 2, a precooling system, a purification system and a cold box. The cold box includes a box body, a heat exchanger 3 and a rectification system inside the box body, and a low-temperature expander 4 and a high-temperature expander 5 connected outside the box body. The filter 1, the air compressor 2, the pre-cooling system and the purification system are connected in sequence, and the pipelines from the purification system are introduced into the heat exchanger 3 after passing through the high-temperature expander 5 and the low-temperature expander 4 in turn, and the heat exchanger 3 The pipeline is divided into two paths, and the first pipeline a is led out from the end of the heat exchanger 3 and then introduced into the rectification system. The second pipeline b is drawn from the middle of the heat exchanger 3 and passes through the low-tempera...

Embodiment 2

[0020] This embodiment is based on the device for obtaining liquid by low-temperature rectification in Example 1, and the method for obtaining liquid by low-temperature rectification includes the following steps:

[0021] Step 1: The raw air passes through the air filter to remove dust and mechanical impurities, enters the raw air compressor to pressurize, then passes through the air pre-cooling system to cool down, and then enters the air purification system to remove H2O, CO2, C2H2, etc. in the raw air pure matter.

[0022] Step 2: The purified air continuously enters the booster end of the high-temperature expander and the low-temperature expander for pressurization, and then enters the heat exchanger after being cooled by the cooler at the booster end. The air in the heat exchanger is divided into two streams; the first stream The air is condensed into liquid air through the heat exchanger, and after being drawn out, it is throttled and directly enters the lower rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com