Condenser set of evaporated compressor

A technology of condensing units and compressors, applied in evaporators/condensers, compressors, irreversible cycle compressors, etc., can solve the problems of cooling tower power increase, large power consumption, and heavy workload, and achieve steel material consumption Effects of reduction, improvement of automation, and construction area saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

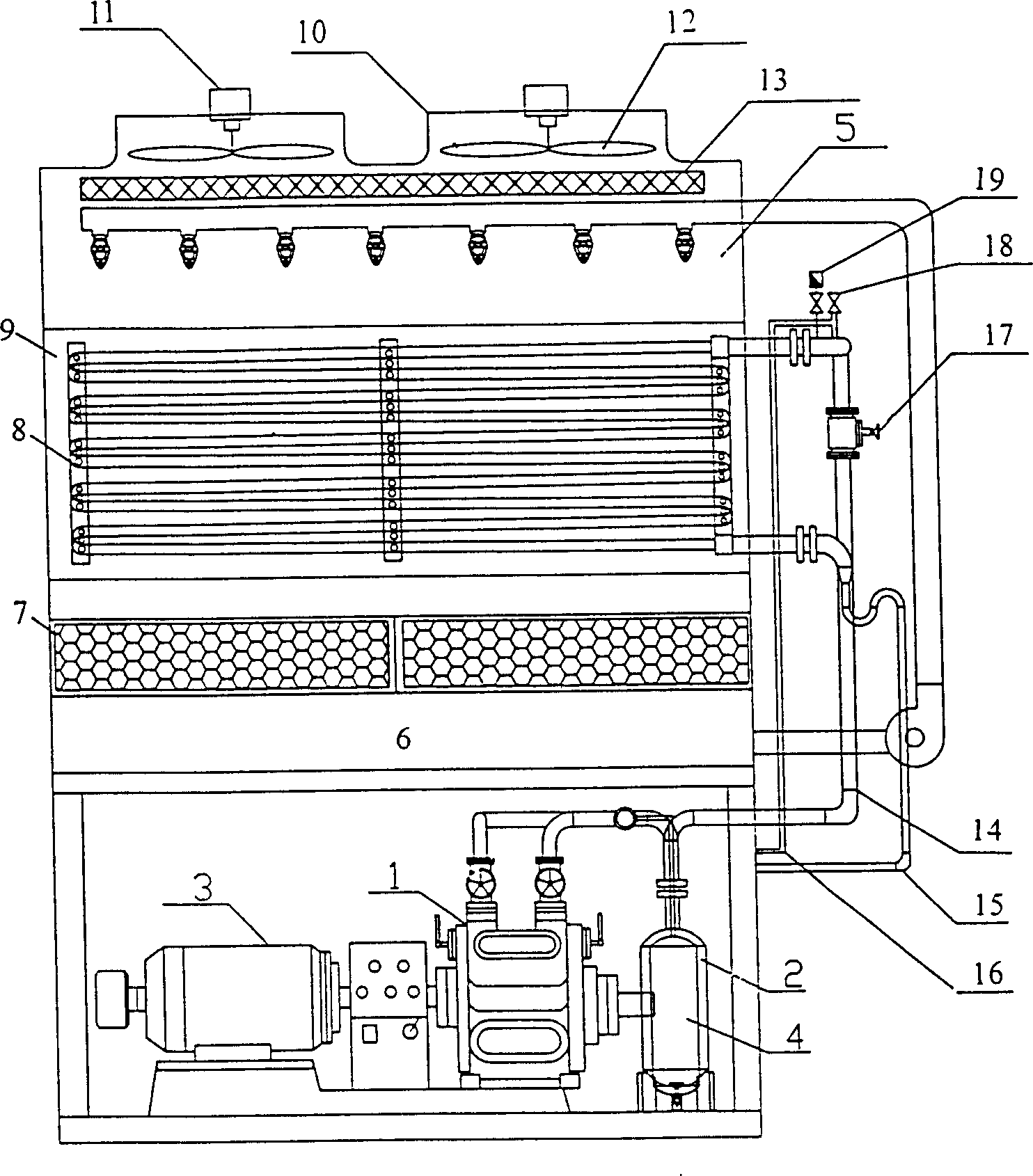

[0008] Referring to the accompanying drawings, its structure includes a condenser, a compressor 1, a liquid receiver 3, an oil collector 4, and an oil separator 2. After the ammonia compressor is started by the compressor 1, it produces refrigerated oil and refrigerated liquid, which are mixed to generate high pressure. , one way is sent to oil collector 4, and the mixed gas generated by the other way is sent to oil separator 2; The liquid flows into the liquid receiver 3; the oil separator 2 decomposes the mixed gas produced by the compressor 1, and the refrigerated liquid gas is sent to the condenser, and after the condenser is cooled by cooling water, the gas is converted into liquid and flows upward into the liquid receiver 3. The lower liquid and oil are separated again and one way flows into the oil separator 2, and the other way flows into the liquid reservoir 3. The condenser is an evaporative condenser 5, and the spray pipe in the evaporative condenser 5 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com