Cooling system with refrigerant for air conditioning and lowering temperature of engine

a technology of engine cooling and refrigerant, which is applied in the direction of machines/engines, combustion air/fuel air treatment, light and heating apparatus, etc., can solve the problems of short life span, excessively high engine system temperature, and long period of engine running fiercely, etc., to prolong the length of the cooling system, increase the contact area, and enhance the effect of engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

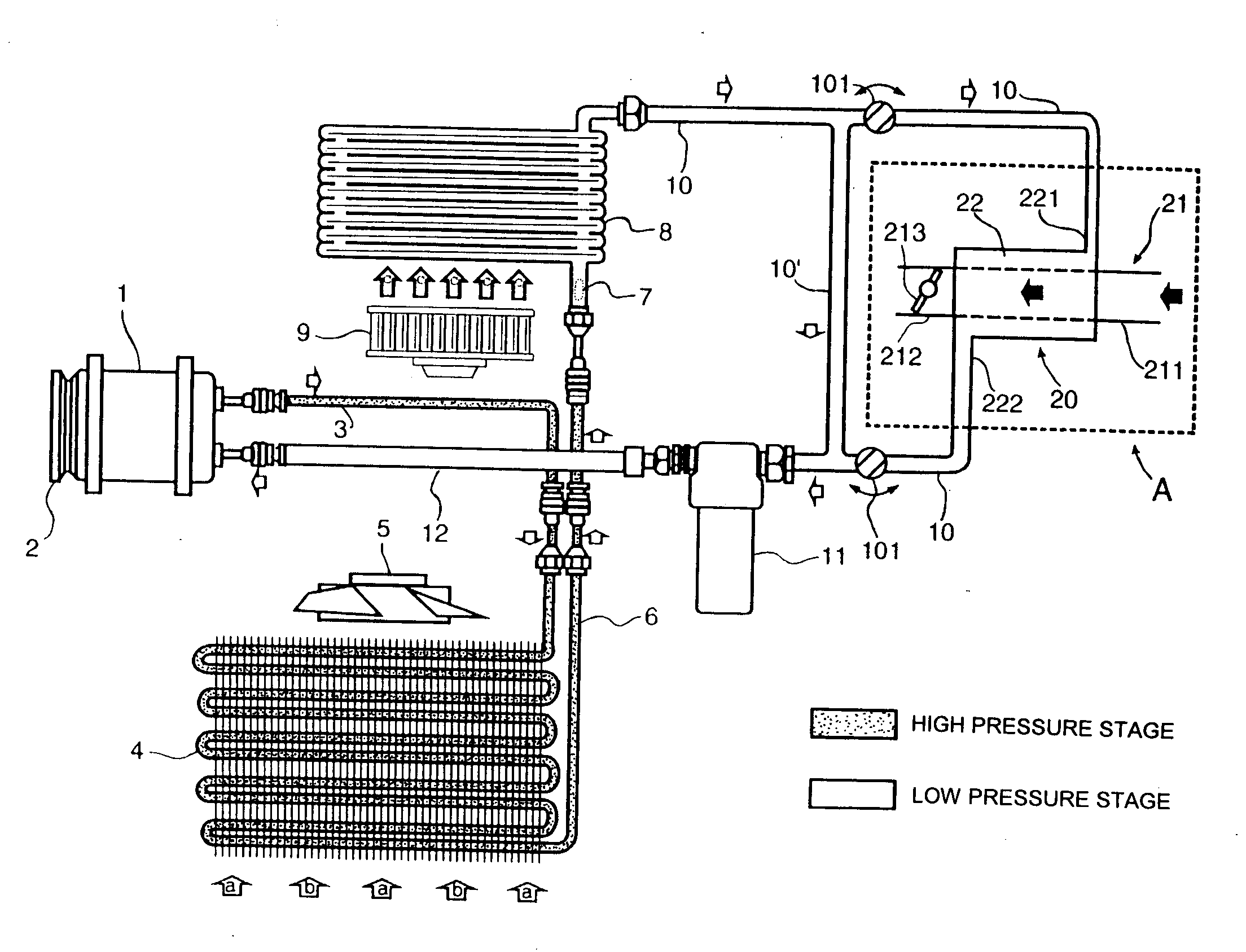

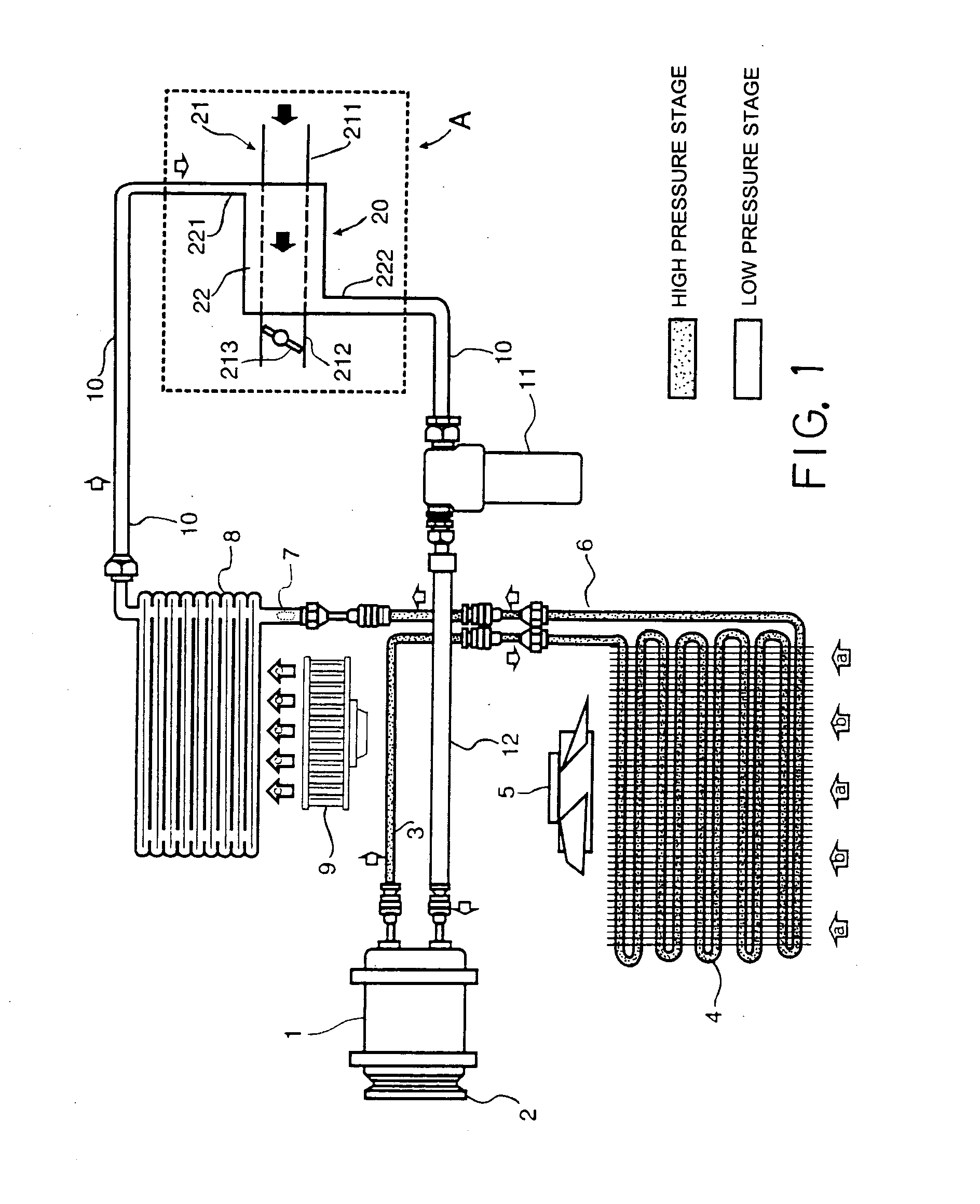

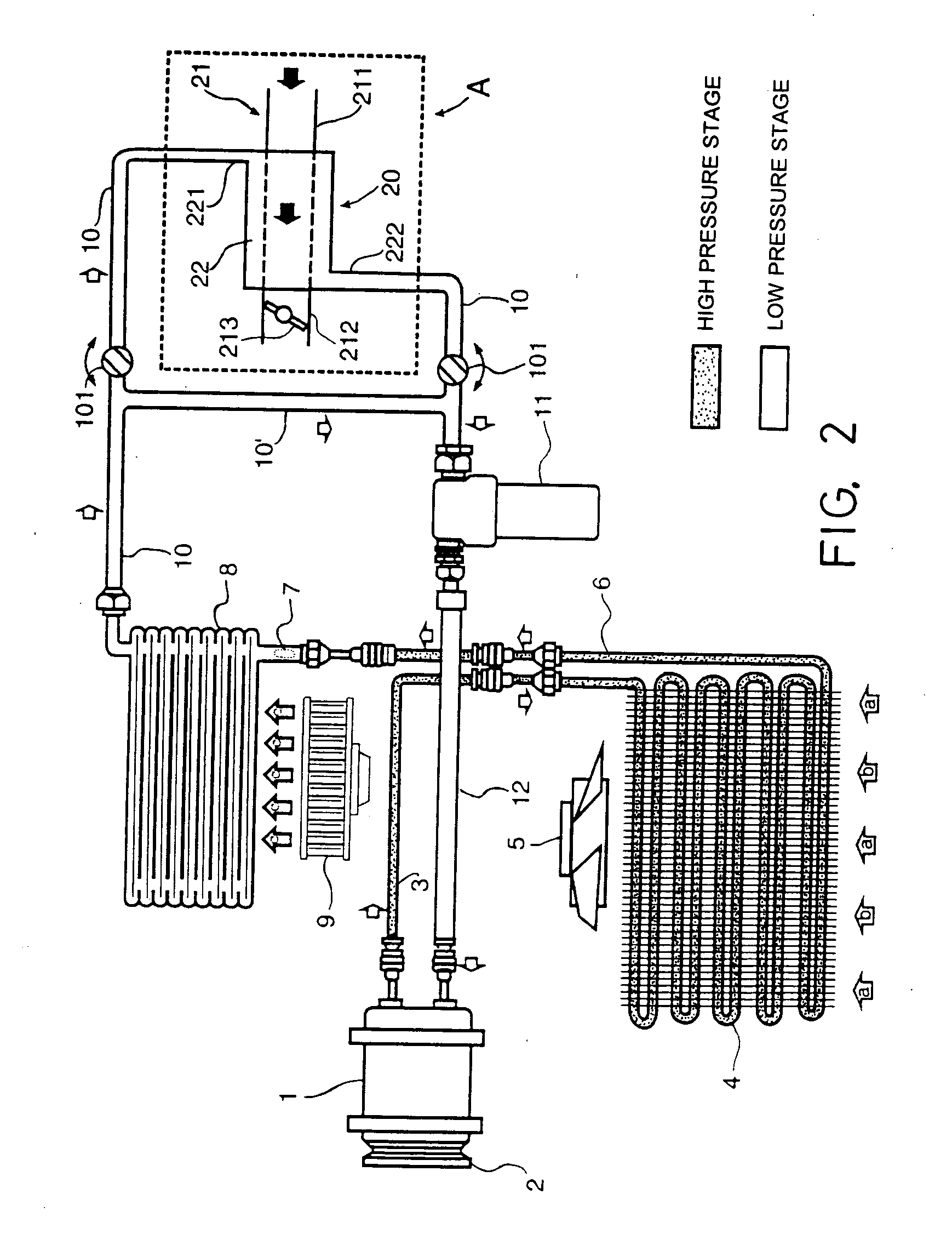

[0015] Referring to FIG. 1, a cooling system with refrigerant according to the present invention includes a compressor 1, a pulley 2, a condenser 4, a connecting pipe 3, which is disposed between the compressor 1 and the condenser 4, a fan 5 for the condenser 4, an expansion valve 7, an evaporator 8, a connecting pipe 6, which is disposed between the condenser and the evaporator 8, a cold air fan 9, a dehumidifying water collector 11, a connecting pipe 10, which is disposed between the evaporator and the dehumidifying water collector and a connecting pipe 12, which is disposed between the dehumidifying water collector and the compressor. The preceding components are basic elements required for constituting a car room of an air conditioning system. The route from the compressor 1 and the connecting pipe 3 to the expansion valve 7 via the condenser 4 is a high pressure stage and the route after the expansion valve 7 to the connecting pipe 12 via the evaporator 8 is a low pressure stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com