Internal heat exchanger assembly

一种内部热交换器、组件的技术,应用在热交换设备、过热器、制冷组件等方向,能够解决空间有限、困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

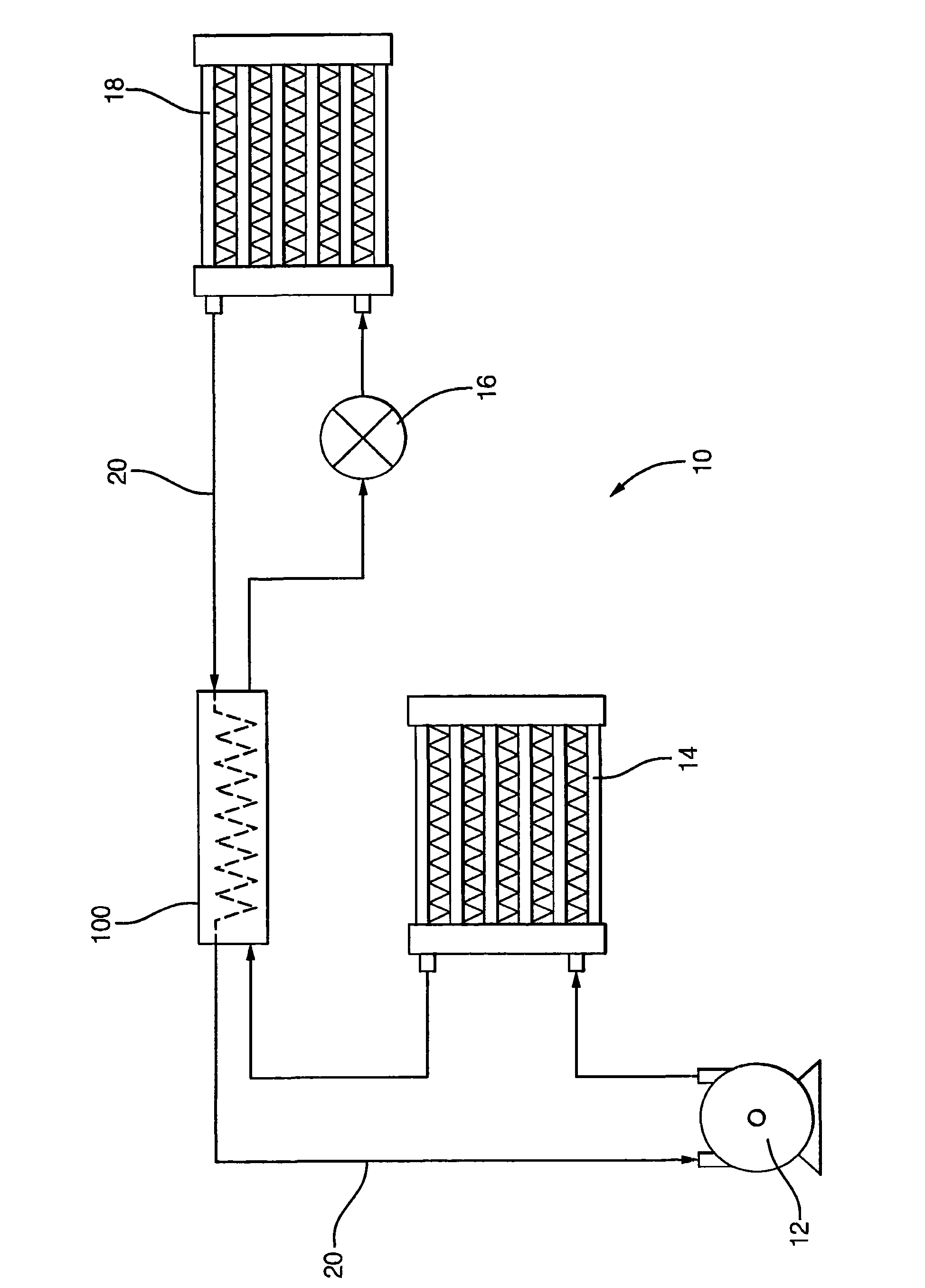

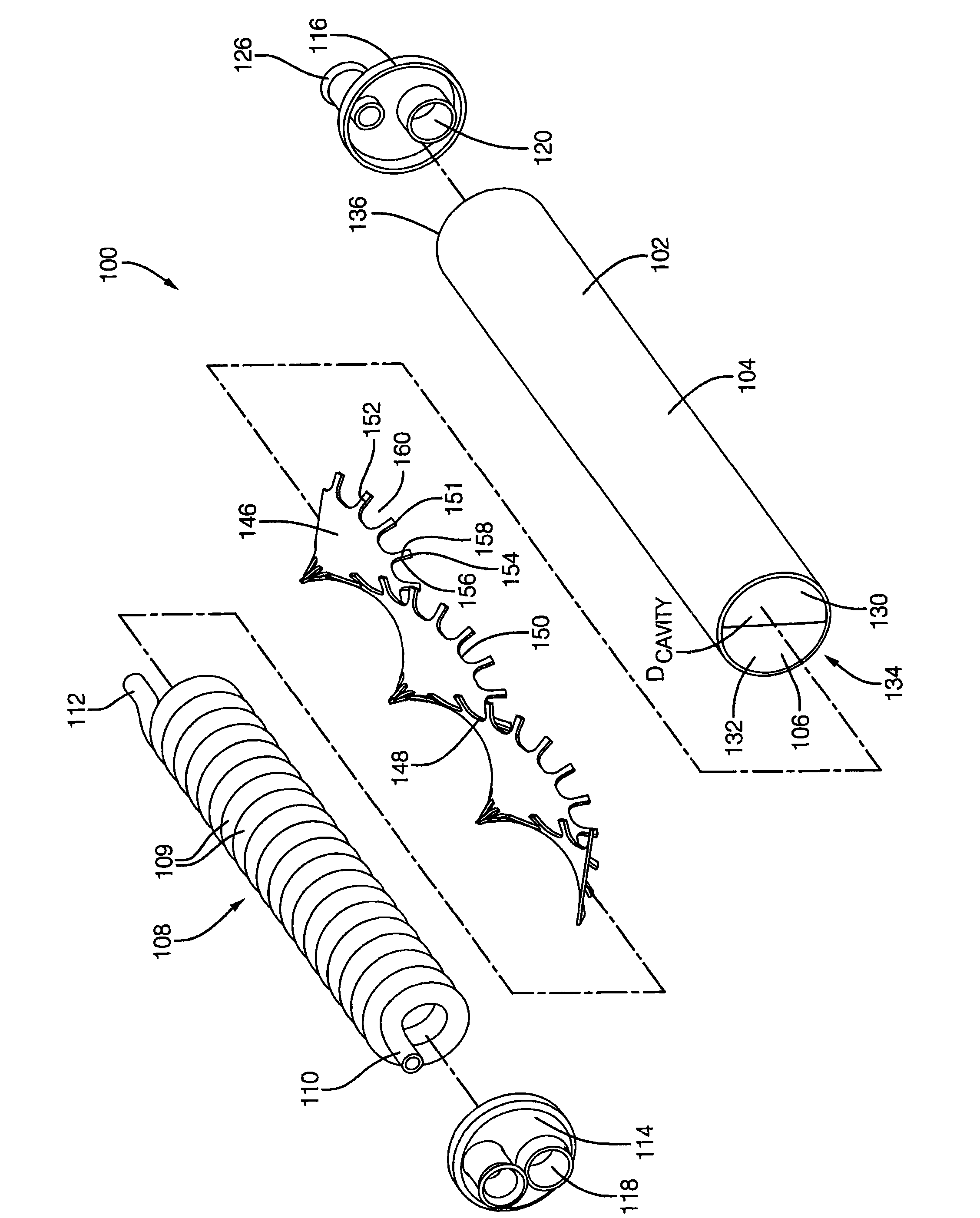

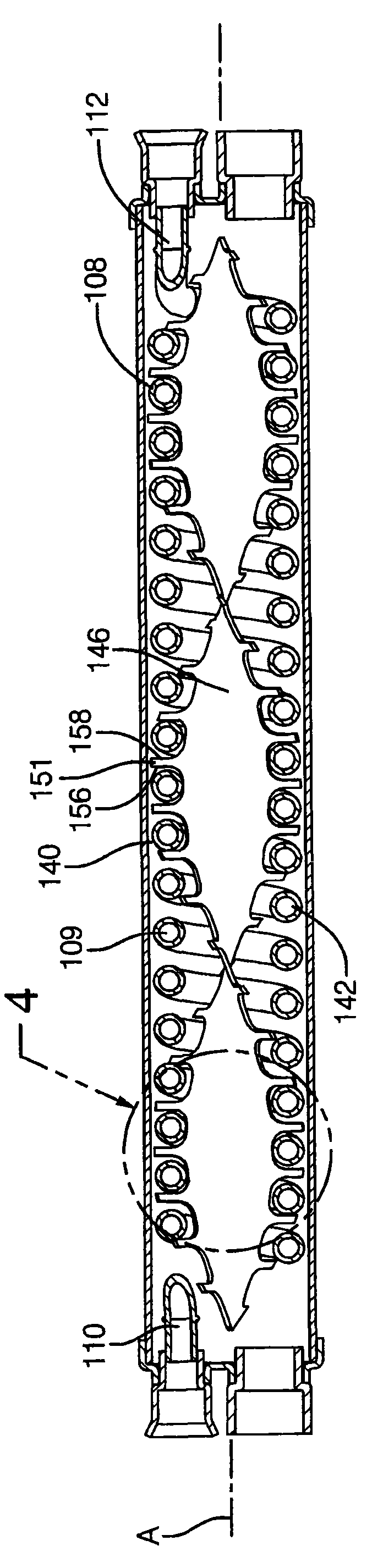

[0020] According to a preferred embodiment of the present invention, refer to Figure 1-4 , the air conditioning system 10 has a compressor 12, a condenser 14, an expansion device 16, an evaporator 18, and a refrigerant pipe 20 hydraulically connecting the above components in series. The air conditioning system 10 further includes an internal heat exchanger 100 to increase the heat transfer capability of the air conditioning system 10 .

[0021] Such as figure 1 As shown in , the low-pressure vapor refrigerant discharged from the evaporator 18 is sucked by the compressor 12 and compressed into a high-pressure vapor refrigerant, which is then discharged to the condenser 14 . In the condenser 14, the high-pressure vapor refrigerant condenses into high-pressure liquid refrigerant. The high pressure liquid refrigerant then passes through an expansion device 16 that regulates refrigerant flow to an evaporator 18 where it expands to a low pressure vapor refrigerant as it absorbs h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com