Online leakage measuring method and system for circulating work medium of thermal power set

A technology of circulating working fluid and thermal power units, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve the problem of difficult online measurement of circulating working fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Taking the rated working condition of a supercritical 600MW unit as an example, when the external leakage of the main pipeline is 20t / h, the pipeline efficiency is 98.3%, and the coal consumption for power supply is 290.4g / kw h. Not counting the leakage of the main pipeline, the coal consumption increases 2g / kw·h, the pipeline efficiency dropped by 0.7%. It can be seen that ignoring the leakage of the main pipeline and setting the pipeline efficiency as a fixed value will cause errors when evaluating the thermal economy of the whole plant, which should be paid attention to.

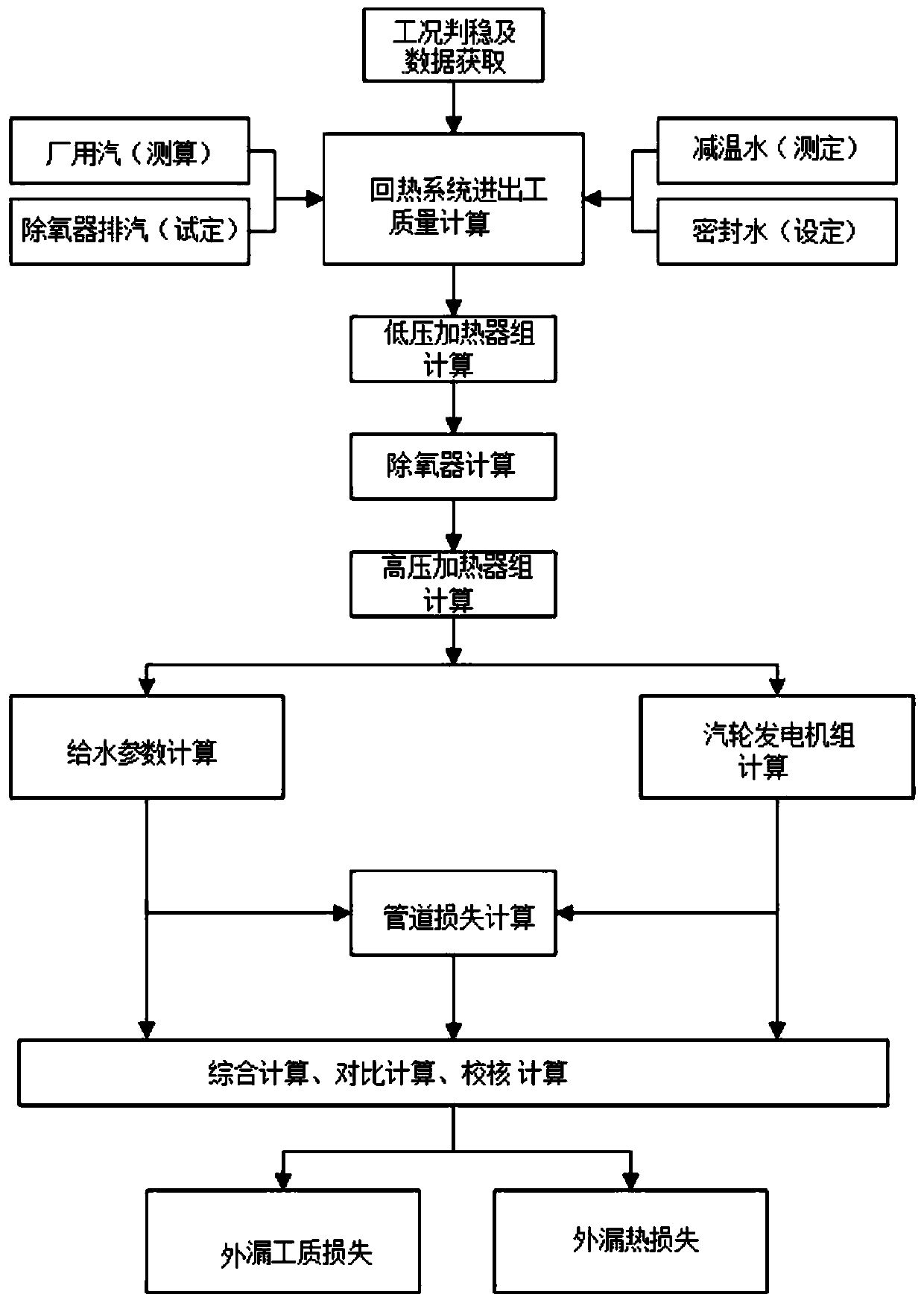

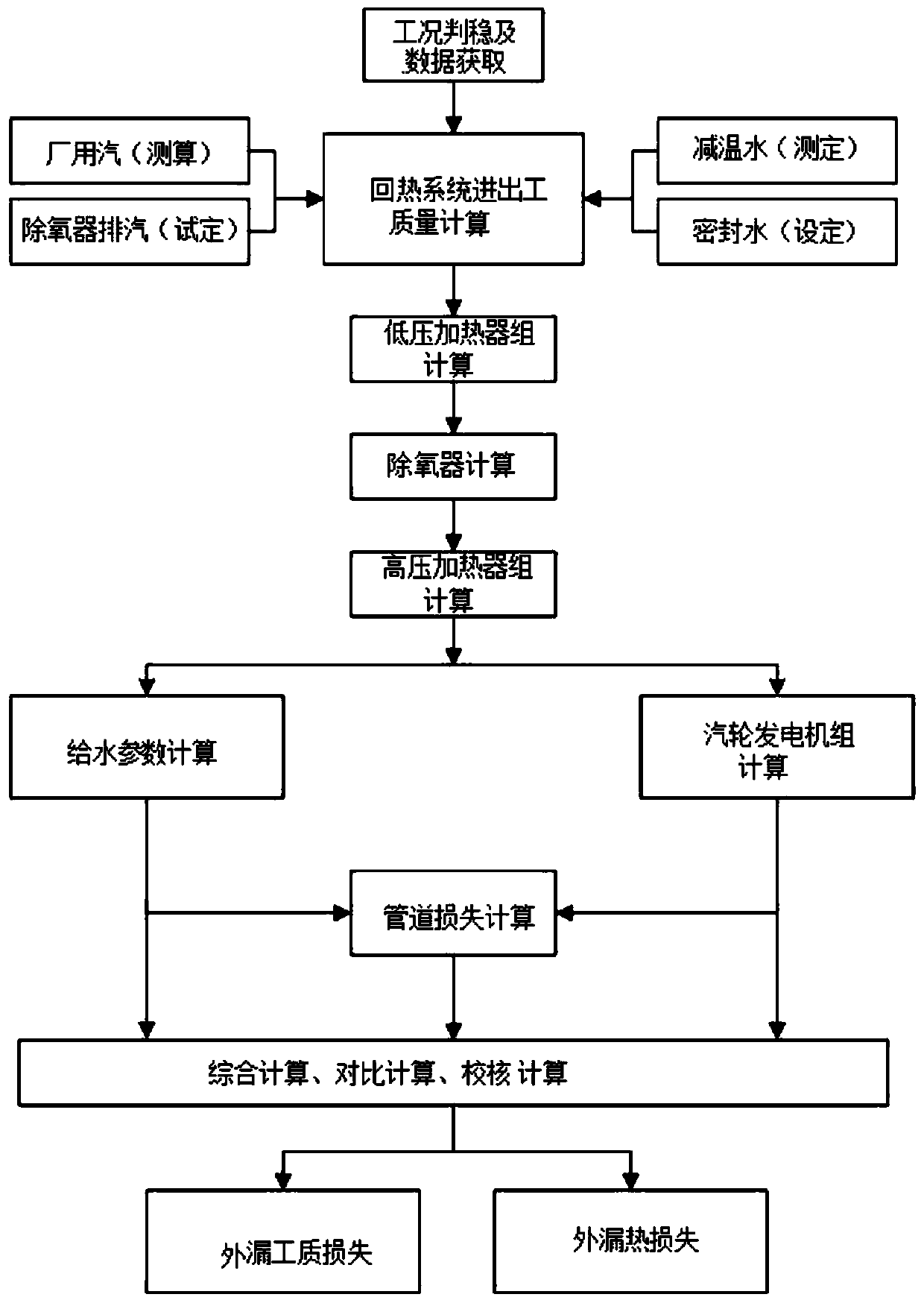

[0033] Such as figure 1 Shown is a flow chart of a method for on-line measurement of circulating working fluid leakage of a thermal power unit, which specifically includes the following steps:

[0034] 1) Working condition judgment and data acquisition:

[0035] Read the required primary parameters from the distributed control system DCS of the unit and the plant-level monitoring and communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com