Acid regenerated flue gas treatment method and system

A flue gas treatment system and flue gas treatment technology, applied in the field of acid regeneration flue gas treatment and acid regeneration flue gas treatment system, can solve the problem of affecting the heat exchange efficiency and normal use of heat exchangers, the effect of dust content is not very obvious, and the graphite Heat exchanger graphite block hole blockage and other problems, to achieve the effect of eliminating psychological discomfort, excellent emission indicators, and reducing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

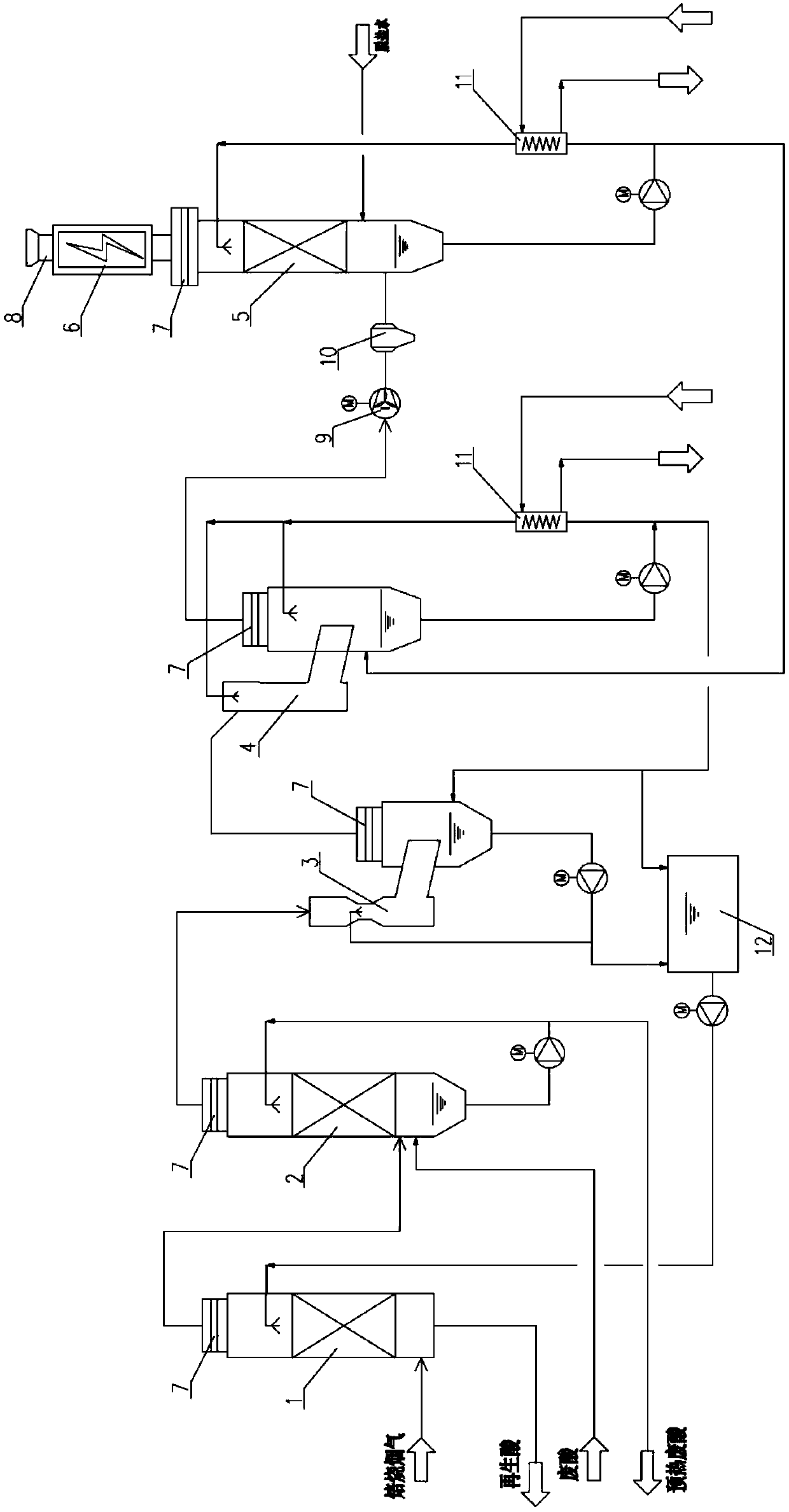

[0041] like figure 1 , the embodiment of the present invention provides a method for treating acid regeneration flue gas, comprising the following steps:

[0042] Step 1, after the acid regeneration flue gas is cooled by the Venturi pre-concentrator, it is sent to the absorption tower 1 for acid absorption;

[0043] Step 2, the flue gas treated by the absorption tower 1 is sent to the waste acid washing tower 2, and the waste acid is sprayed to remove dust from the flue gas, and the waste acid is preheated at the same time, and the preheated waste acid can be sent to the pre-concentrator for further processing. waste acid concentration;

[0044] Step 3, performing first-stage washing treatment on the flue gas treated by the waste acid washing tower 2, so as to remove part of the dust and acid mist in the flue gas;

[0045] Step 4, spraying and cooling the flue gas after the first stage of washing;

[0046] Step 5, spraying and cooling the flue gas for the second stage of wa...

Embodiment 2

[0065] An embodiment of the present invention provides an acid regeneration flue gas treatment system, including an absorption tower 1, a waste acid scrubber 2, a Venturi scrubber 3, a spray cooling tower 4, and a second-stage scrubber sequentially connected through a flue gas pipeline 5. Dust removal device and exhaust chimney 8. The waste acid washing tower 2 is provided with a waste acid spraying unit.

[0066] It can be understood that the waste acid spraying unit provided in the above waste acid washing tower 2 can adopt a conventional arrangement of nozzles in the tower, and the specific structure will not be described here; the waste acid spraying unit is connected with a waste acid supply pipe , There is a waste acid collection tank at the bottom of the tower, and the collected preheated waste acid can be sent to the Venturi pre-concentrator for further concentration treatment and then sent to the spray roaster. The waste acid washing tower 2 is preferably a packed tow...

Embodiment 3

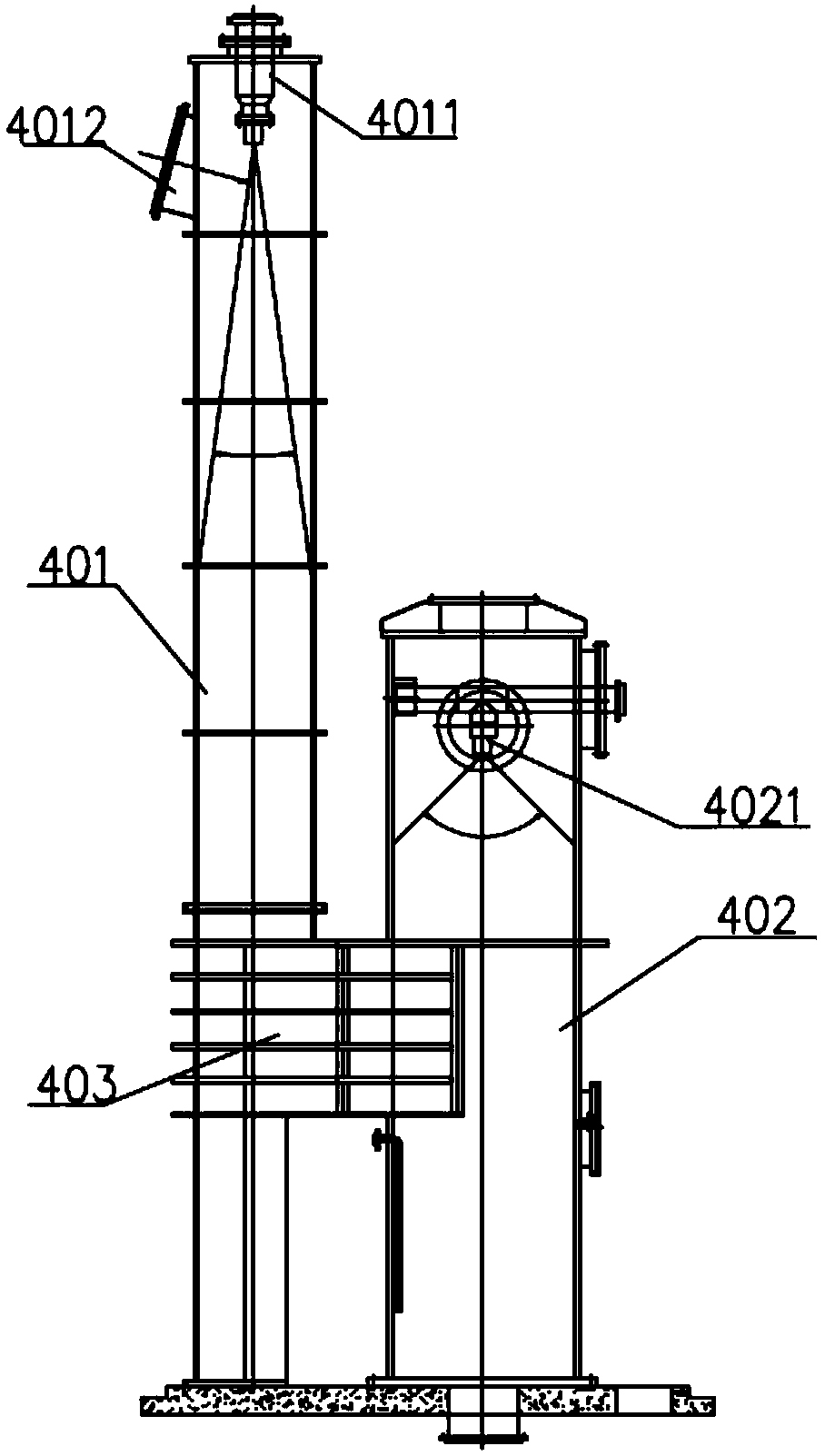

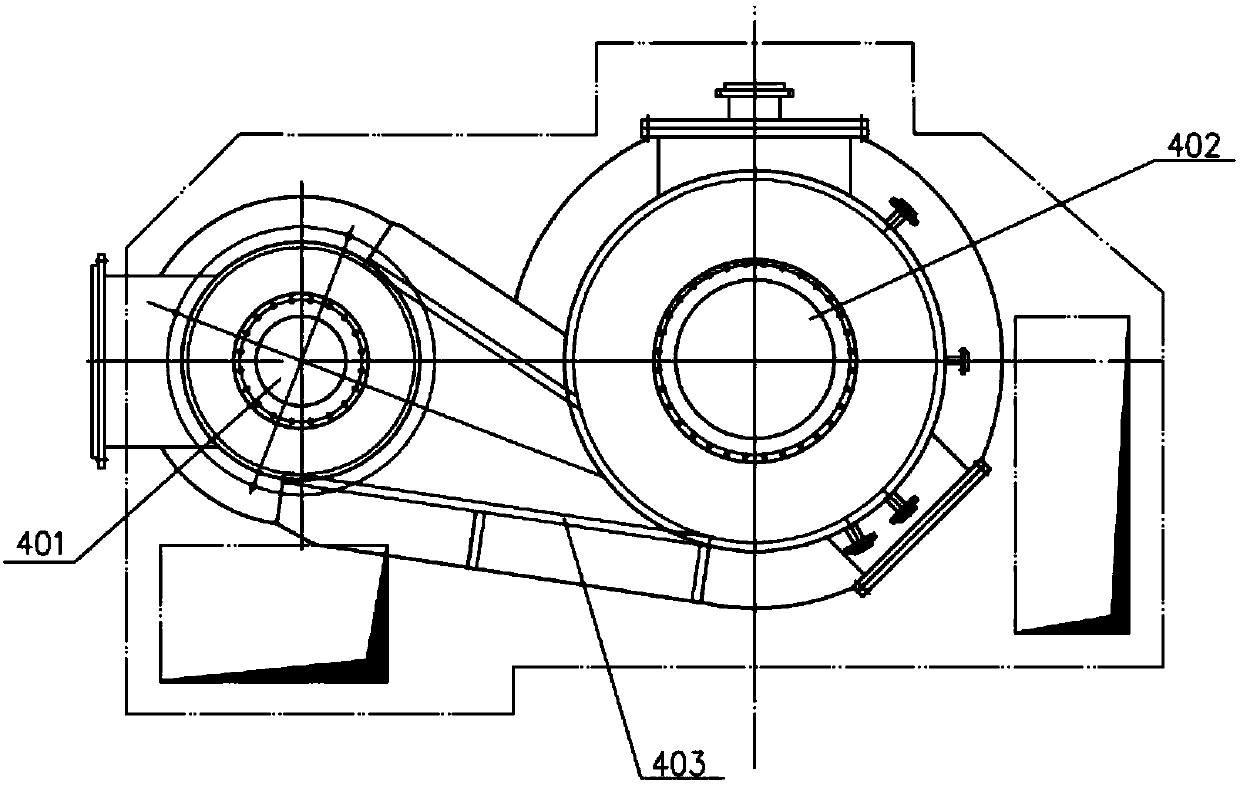

[0085] This embodiment provides a split spray cooling tower 4, which can be used in the first and second embodiments above.

[0086] like figure 2 and image 3 , the split spray cooling tower 4 includes a first tower body 401 and a second tower body 402 arranged left and right (that is, both are arranged along the horizontal direction), and the first tower body 401 is supported on the ground by a base, then The bottom of the first tower body 401 is located above the bottom of the second tower body 402; both the first tower body 401 and the second tower body 402 are provided with spray units;

[0087] The upper part of the first tower body 401 is provided with a flue gas inlet, and the lower part is provided with a material outlet, and the bottom of the material outlet is flush with the bottom of the first tower body 401, so that the material outlet can be used as the flue gas outlet of the first tower body 401 and spray liquid outlet; the bottom of the second tower body 402...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com