Purification method of ethyl acetate

A technology of ethyl acetate and a purification method, which is applied in chemical instruments and methods, carboxylic acid ester preparation, chemical industry, etc., can solve the problems of low primary yield of ethyl acetate and high energy consumption in operation, and achieve energy consumption reduction, significant The effect of practicality and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

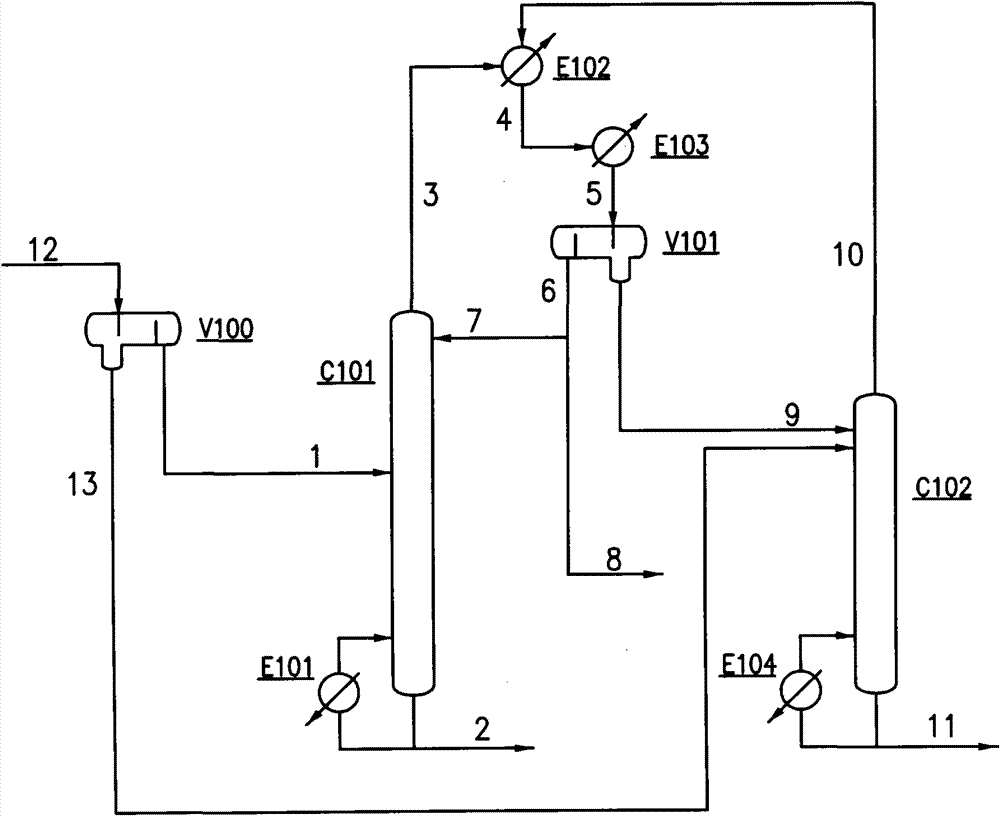

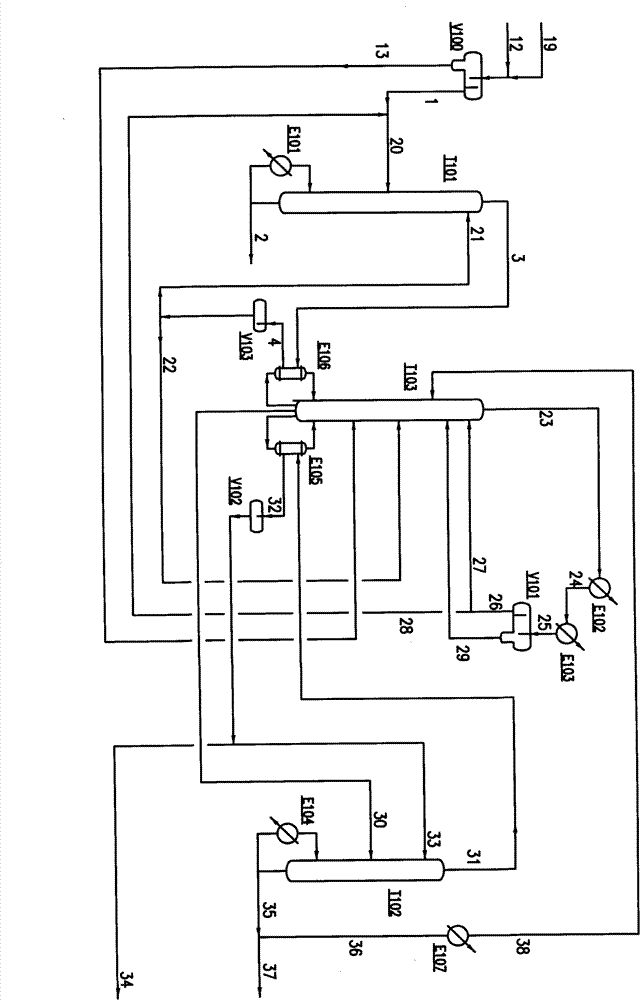

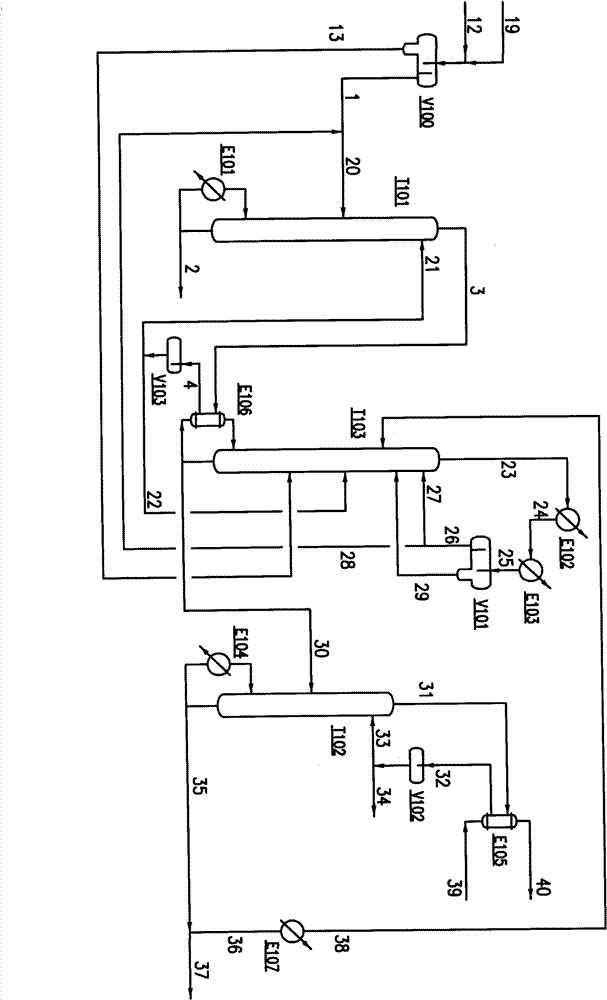

Method used

Image

Examples

Embodiment 2

[0071] The typical operating conditions of each main equipment of embodiment 2 are the same as embodiment 1.

[0072] Adopt the ethyl acetate purification method that the present invention provides and widely adopt two towers ethyl acetate refining process operation energy consumption contrasts as follows at present:

[0073] In the conventional two-tower ethyl acetate refining process widely used at present, the steam consumption for producing ethyl acetate is about 1.2 tons of steam per ton of ethyl acetate product.

[0074] Adopt the ethyl acetate purification method that the present invention provides, steam consumption is about 0.55 ton steam / ton ethyl acetate product.

[0075] Adopt the ethyl acetate purification method provided by the present invention to compare with the conventional two-tower ethyl acetate refining process method widely used at present, calculate by 100,000 tons / year ethyl acetate plant (ethyl acetate output is 12.5 tons / hour, annual operation The nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com