Filling material hypoxia removing nitric dephosphorization technique

A technology for nitrogen and phosphorus removal and process, which is applied in the direction of aerobic and anaerobic process treatment, and can solve the problems of not considering whether there is denitrification process in aerobic zone, large design capacity of denitrification tank, low volumetric efficiency of reaction tank, etc. , to achieve the effect of saving process energy consumption, saving aeration energy consumption, and increasing the concentration of nitrifying bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

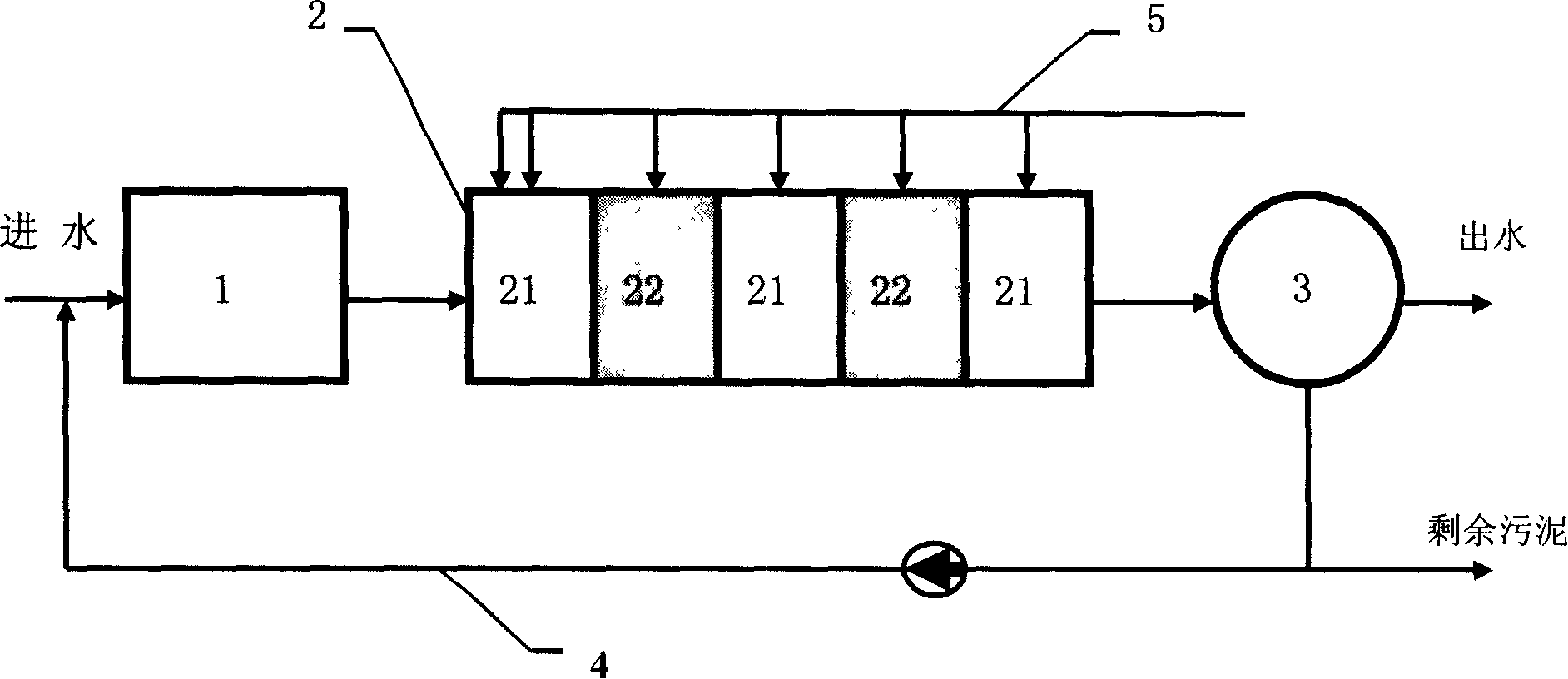

[0021] The present invention is further described with reference to the above-mentioned accompanying drawings.

[0022] The process of the present invention consists of a (deficiency) anaerobic tank 1, an aeration tank 2, a secondary sedimentation tank 3, a sludge return system 4 and an aeration system 5. An agitation device is arranged in the (deficiency) anaerobic tank 1 , and a filler area 21 and a low-oxygen area 22 are arranged at intervals in the aeration tank 2 , and the aeration tank 2 communicates with the aeration system 5 . The aeration system 5 controls the dissolved oxygen levels set in the filling area 21 and the hypoxic area 22 through automatic control to ensure the effect of water treatment.

[0023] 1. Treatment of urban sewage

[0024] Before the urban sewage enters the process of the present invention, the sewage is firstly pretreated by grids and degreasing, and then pretreated by the short-time primary sedimentation tank in front of the process of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com