Artificial wetlands system for purifying roof rainwater containing washing wastewater

A constructed wetland system, rainwater technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Small area, avoid clogging, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

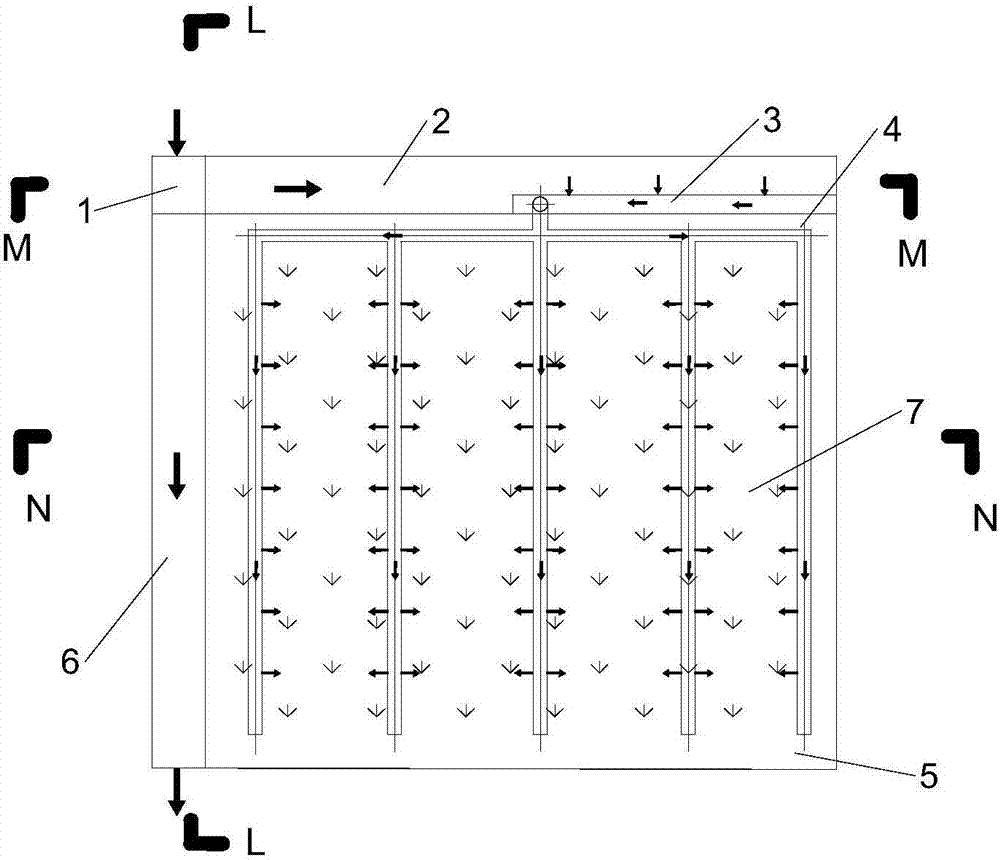

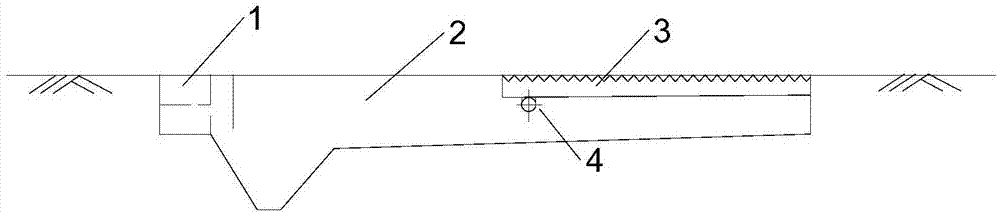

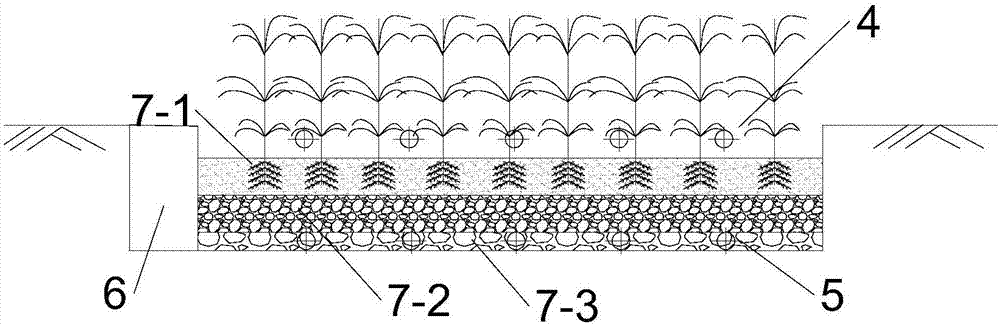

[0022] Such as figure 1 As shown in the figure, a constructed wetland system for purifying roof rainwater containing laundry wastewater includes a rain-sewage diversion well 1, a grit chamber 2, a water distribution channel 3, a water distribution pipe 4, a wetland treatment area 7, a water collection pipe 5 and a flood discharge ditch6. Such as Figure 5 and Figure 6 As shown, the water inlet of the rain and sewage diversion well 1 is connected to the rainwater pipe 1-1 on the roof of the building, and the water outlet is respectively connected to the flood discharge ditch 6 and the grit chamber 2, and the rain and sewage diversion well 1 is provided with a diversion valve 1-2 and a filter screen 1-3 , when the flow of heavy rain into the rainwater pipe is relatively large, and the water level in the rainwater diversion well 1 is higher than the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com