Coated drip irrigation tube/belt production method

A production method and technology for drip irrigation pipes, which are applied in the directions of spraying devices and spraying devices, can solve problems such as blocking the water outlet, and achieve the effects of prolonging the service life, improving the irrigation efficiency, and having a broad promotion prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

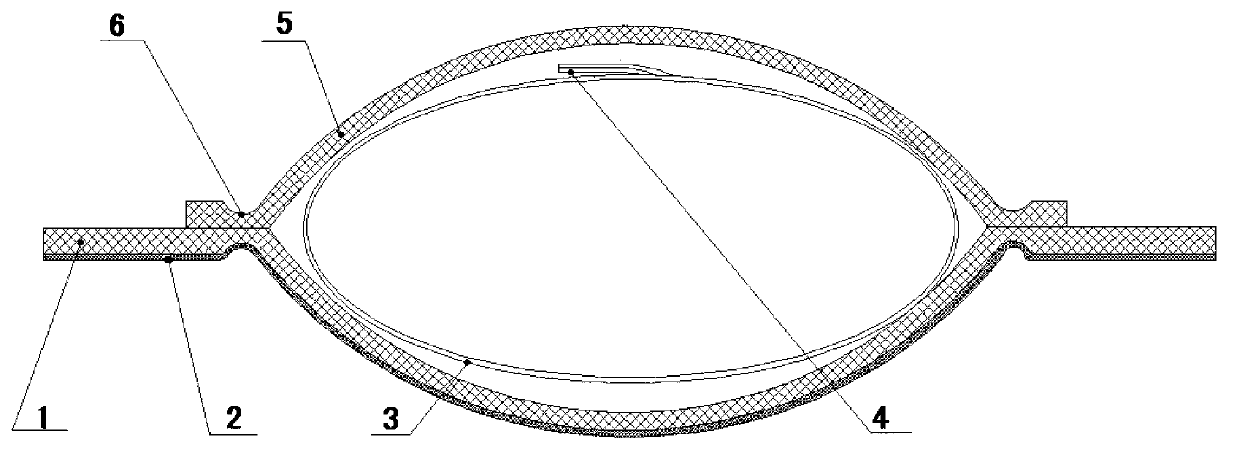

[0037] figure 1 Shown is a schematic diagram of the coating structure of the labyrinth drip irrigation belt widely used at present with the method of the present invention, the seepage side seam 4 of the drip irrigation belt is located in the middle of the filter mantle, and the filter mantle is heat-sealed and pressed by the upper and lower two-layer coating Composed of stitching or stitching, the upper layer is a fiber layer of water-permeable material, such as non-woven fabric, open foam, etc. The following is a water-blocking material, such as ordinary plastic film. A preferred example given by the present invention is to choose water-permeable fiber material non-woven fabric or open foam plastic for both top and bottom, and a water-blocking film 2 is arranged on the surface of the water-permeable fiber below. And in order to allow the irrigation water to concentrate on the root system of the above crops, the extended side of the lower water-blocking material layer of the...

Embodiment 2

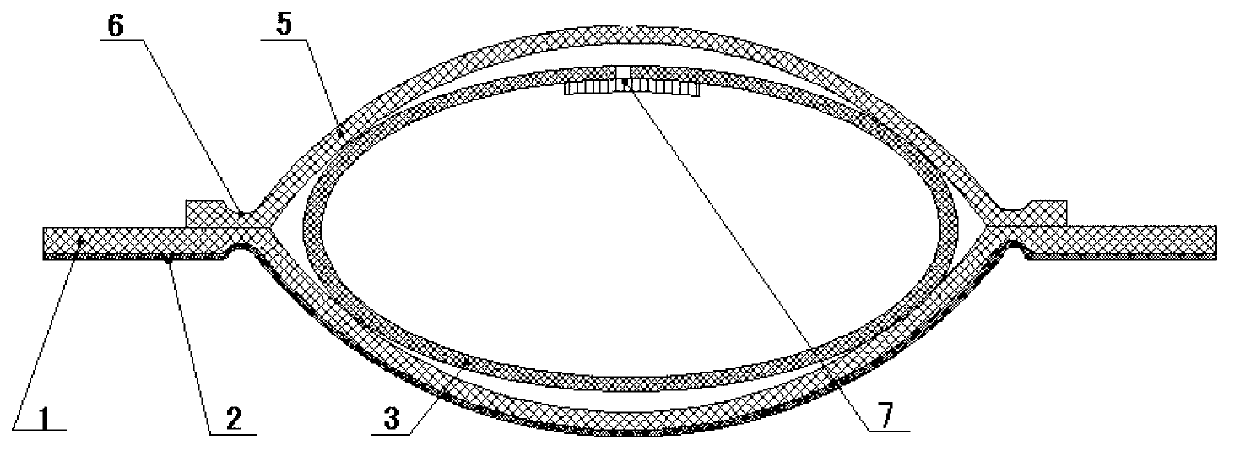

[0039] figure 2 Shown is a schematic diagram of the membrane structure of a labyrinth drip irrigation belt embedded in the patch. The labyrinth patch 7 is also arranged in the middle of the filter mantle, and the others are the same as in Example 1.

Embodiment 3

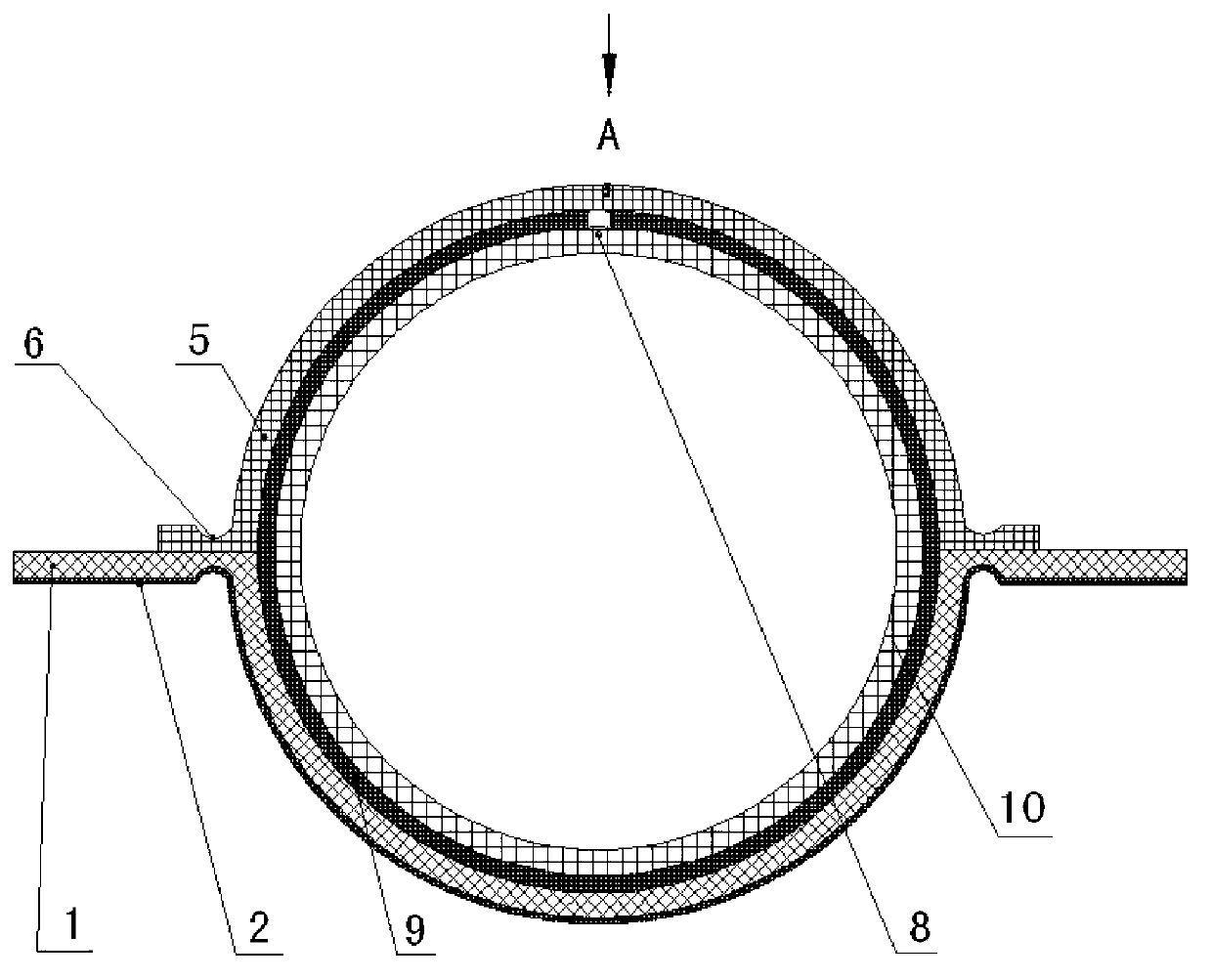

[0041] image 3 Shown is a schematic diagram of the envelope structure of a drip irrigation pipe embedded with a cylindrical dripper. The water outlet hole 8 of the cylindrical dripper 10 is also set in the middle of the filter mantle, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com