Single-effect four-body MVR (mechanical vapor recompression) saline wastewater separation device and separation method thereof

A separation device and salt mixing technology, applied in chemical instruments and methods, water/sewage treatment, multi-stage water treatment, etc., can solve the problems of high energy consumption, energy waste, large volume flow, etc. Heat exchange area and effect of operating energy consumption, cost reduction and operational energy consumption, flow reduction and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

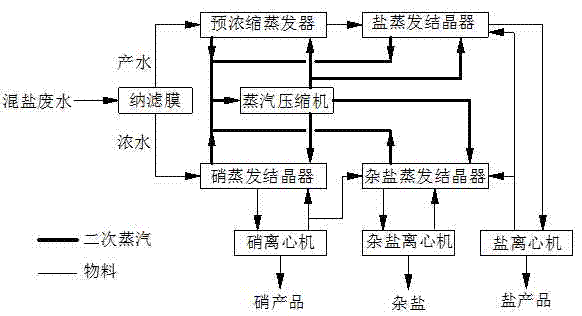

[0033] Such as figure 1 As shown, the secondary steam outlets of the pre-concentration evaporator, salt evaporation crystallizer, nitric acid evaporation crystallizer, and miscellaneous salt evaporation crystallizer are connected to the inlet of the same effect steam compressor, and the outlets of the steam compressor are respectively connected to the pre-concentration evaporator, Heating steam inlet of salt evaporation crystallizer, nitric acid evaporation crystallizer, miscellaneous salt evaporation crystallizer.

Embodiment 2

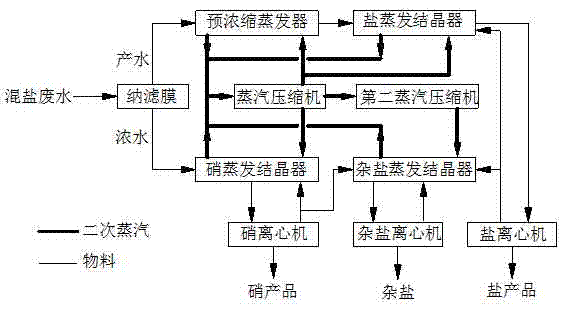

[0035] Such as figure 2 As shown, the secondary steam outlets of the pre-concentration evaporator, salt evaporation crystallizer, nitric acid evaporation crystallizer, and miscellaneous salt evaporation crystallizer are connected to the inlet of the same effect steam compressor, and the outlets of the steam compressor are respectively connected to the pre-concentration evaporator, The heating steam inlet of the salt evaporation crystallizer, the nitric acid evaporation crystallizer and the inlet of the second steam compressor, the outlet of the second steam compressor is connected with the heating steam inlet of the miscellaneous salt evaporation crystallizer.

[0036] The specific implementation method of the one-effect four-body MVR mixed salt wastewater separation method using the above separation device is as follows.

[0037] 1. Mixed salt wastewater passes through the nanofiltration membrane to obtain sodium chloride-rich product water and sodium sulfate-rich concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com